PSC Proprietary 2000781J MkII MLB Operating Procedure Page 3 of 50

1. Revision History

to

to

Varies Varies See prior revisions for details.

This revision not used as I may be confused for 1 in document number.

J 17Jan19 RH CF

1) General wording and formatting improvements throughout document.

2) Cover page: Updated.

3) Changed all references of STP to NTP.

4) Section 2: Added and updated acronyms.

5) Section 3: Added reference to training record and website check for

latest revision. Reworded Lightband operation descriptions.

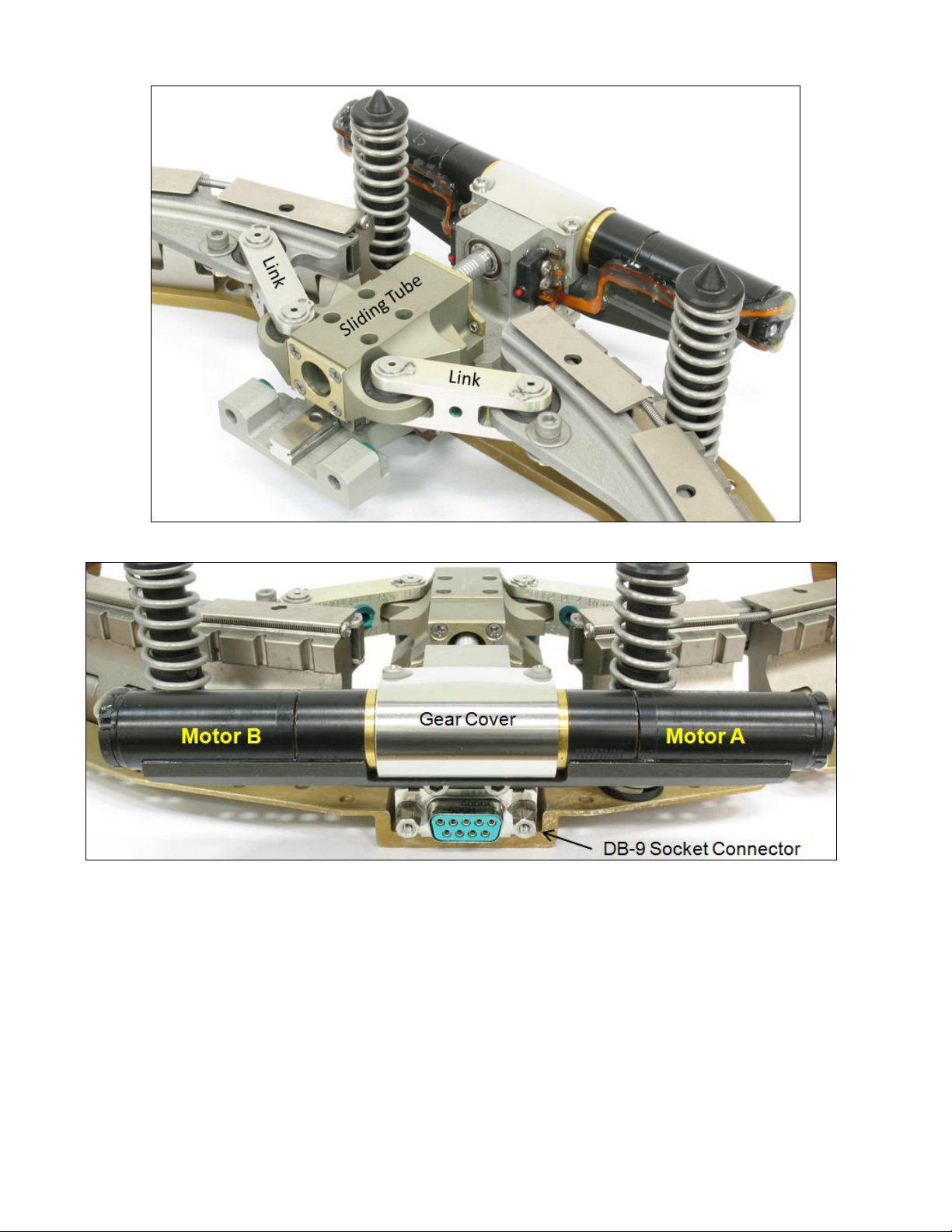

6) Figure 3-1, Figure 3-2, Figure 3-5, Figure 3-6: Updated.

7) Section 3.2: Added equipment and organized by section.

8) Section 4: Added #10

9) Section 6: Added Lower Ring # 5.

10) Figure 6-4: Added.

11) Section 7: Removed training verification step. Added Lightband

circularity note.

12) Step 7.1.4: Added cleaning of Lightband surfaces also.

13) Section 8.1: Reordered several steps.

14) Step 8.1.6: Increased allowable lateral stiffness.

15) Step 8.1.7: Removed pre-mate alignment requirements. Changed to

visibly level.

16) Step 8.1.10: Removed LCT reference.

17) Figure 8-5: Updated.

18) Step 8.2.3: Added detailed resistance measurement examples.

19) Figure 8-6, Figure 8-7: Updated power source symbol.

20) Step 8.2.8: Added.

21) Step 8.2.14: Removed picture as allowable data record.

22) Table 8-1: Reduced MLB13 minimum allowable 2nd peak current.

Reduced MLB31 & MLB38 minimum allowable startup current. Added

note to use current for durations.

23) Step 9.1.3: Added detailed resistance measurement examples.

24) Figure 9-1, Figure 9-2: Updated power source symbol.

25) Step 9.1.8: Added.

26) Step 9.1.13: Removed picture as allowable data record.

27) Figure 9-3: Refined notes.

28) Table 9-1: Added note to use current for durations.

29) Step 10.1.3: Added detailed resistance measurement examples.

30) Figure 10-1, Figure 10-2: Updated power source symbol.

31) Step 10.1.8: Added.

32) Step 10.1.5: Removed picture as allowable data record.

33) Table 10-1: Reduced maximum allowable first peak current. Added

note to use current for durations.

34) Section 12: Changed entire section from an electrical operation to a

manual operation.

35) Section 15: Documents now available on website.

36) Table 15-1: Removed #10 shoulder washer and LCTs. Added

alignment screws. Updated figures.

37) Figure 17-1: Updated power source symbol.

38) Section 18: Added. 2002159E LCT Procedure subsumed into this doc

and simplified. Deleted max allowable LCTs. Allowable LCT mounting