PSR PAT ANTI-TWO-BLOCK Specifications

INSTALLATION, OPERATOR’S & TROUBLESHOOTING

MANUAL

PAT ANTI-TWO-BLOCK

TABLE OF CONTENTS

1.

GENERAL INFORMATION.........................................................................................................1

2.

WARNINGS.................................................................................................................................1

3.

OPERATION ...............................................................................................................................2

SYSTEMDESCRIPTION.........................................................................................................2

CONTROL IDENTIFICATION ..................................................................................................2

PRE-OPERATION INSPECTION.............................................................................................4

OPERATIONAL TESTS...........................................................................................................6

4

INSTALLATION ..........................................................................................................................7

SYSTEMKITS.........................................................................................................................7

INSTALLATION, HYDRAULIC CRANE....................................................................................7

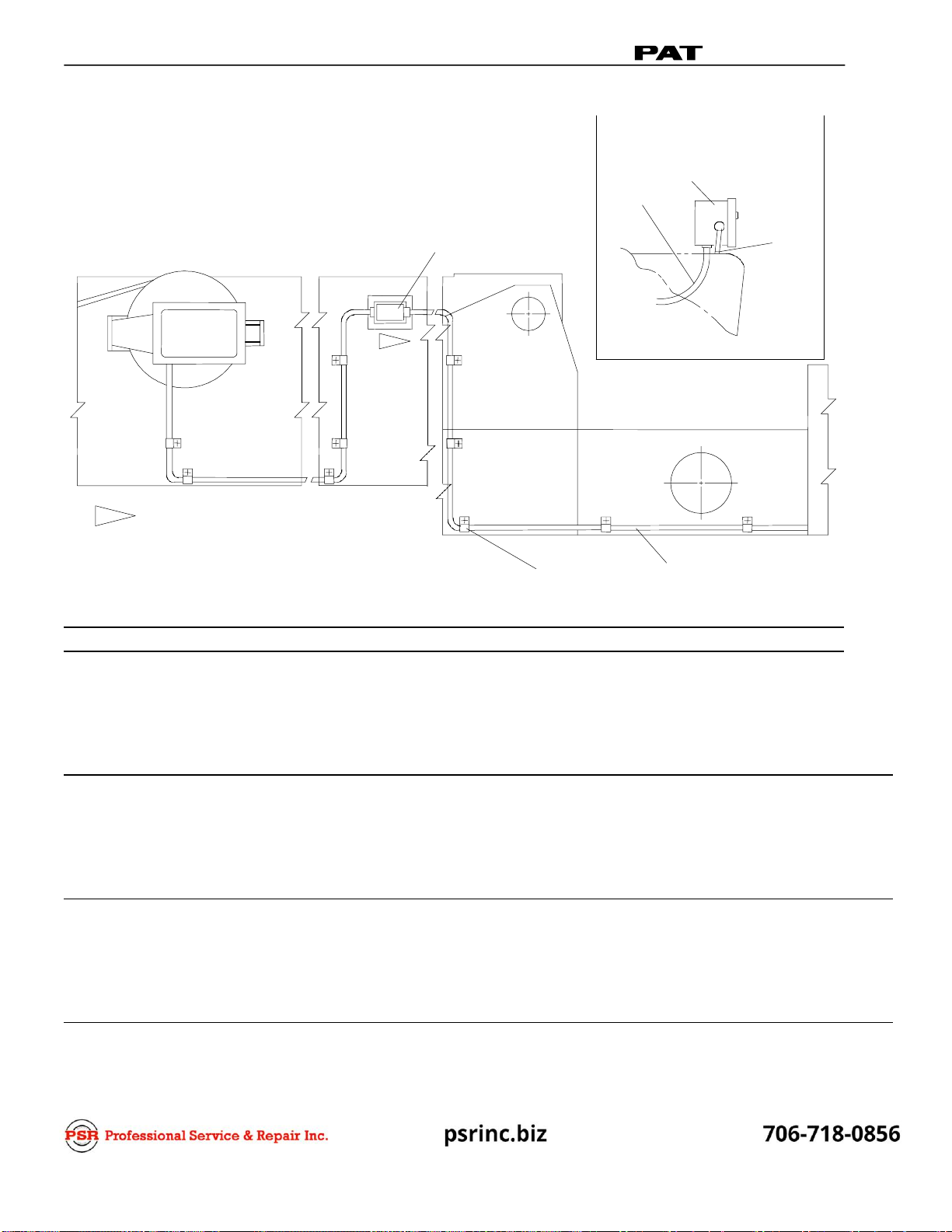

DRAWING 1. 031-300-060-653 A2B CONSOLE INSTALLATION KIT - PARTS LIST..................8

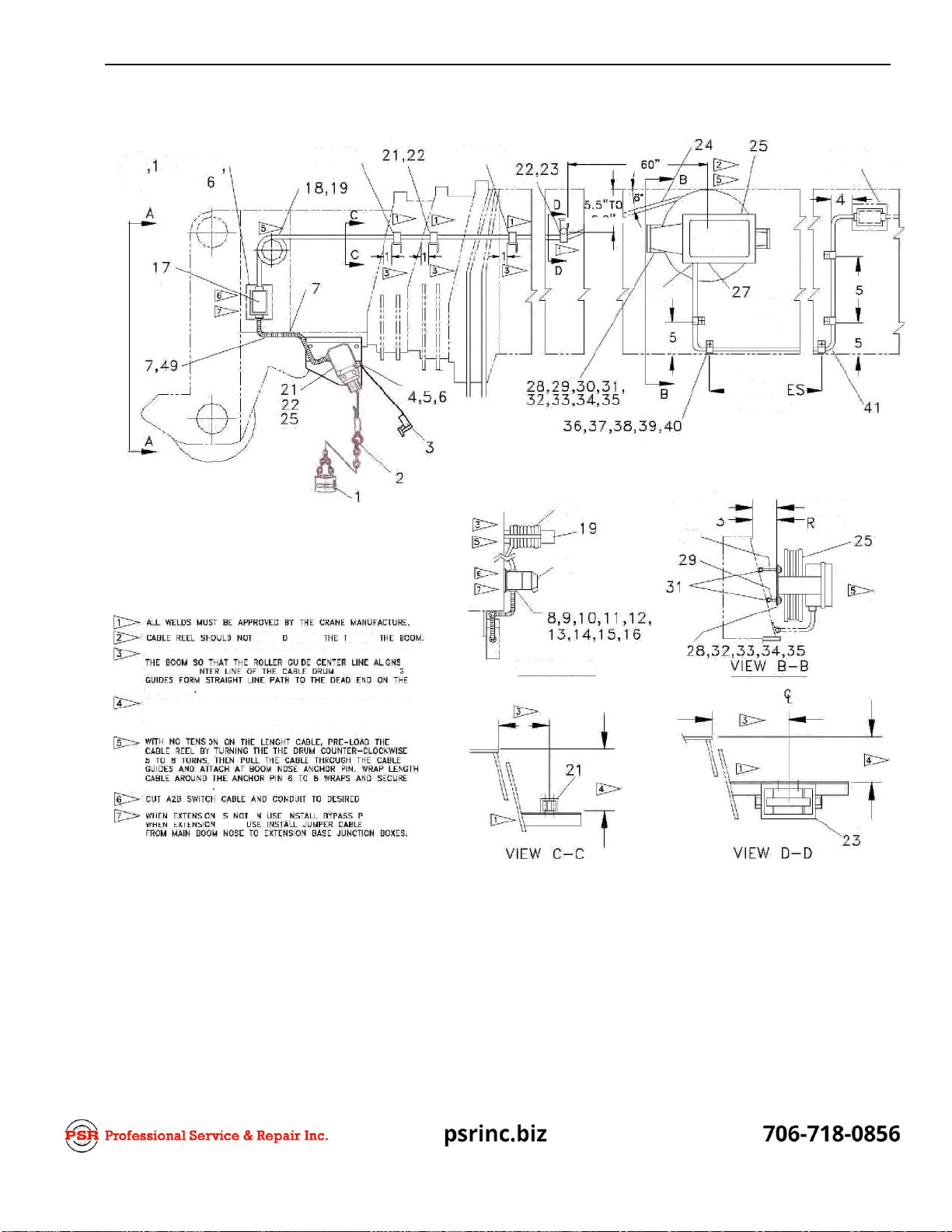

DRAWING 1. 031-300-060-654 A2B MAIN BOOM INSTALLATION KIT - PARTS LIST...............9

DRAWING 3. 031-300-100-443 A2B MOUNTING KIT - PARTS LIST........................................11

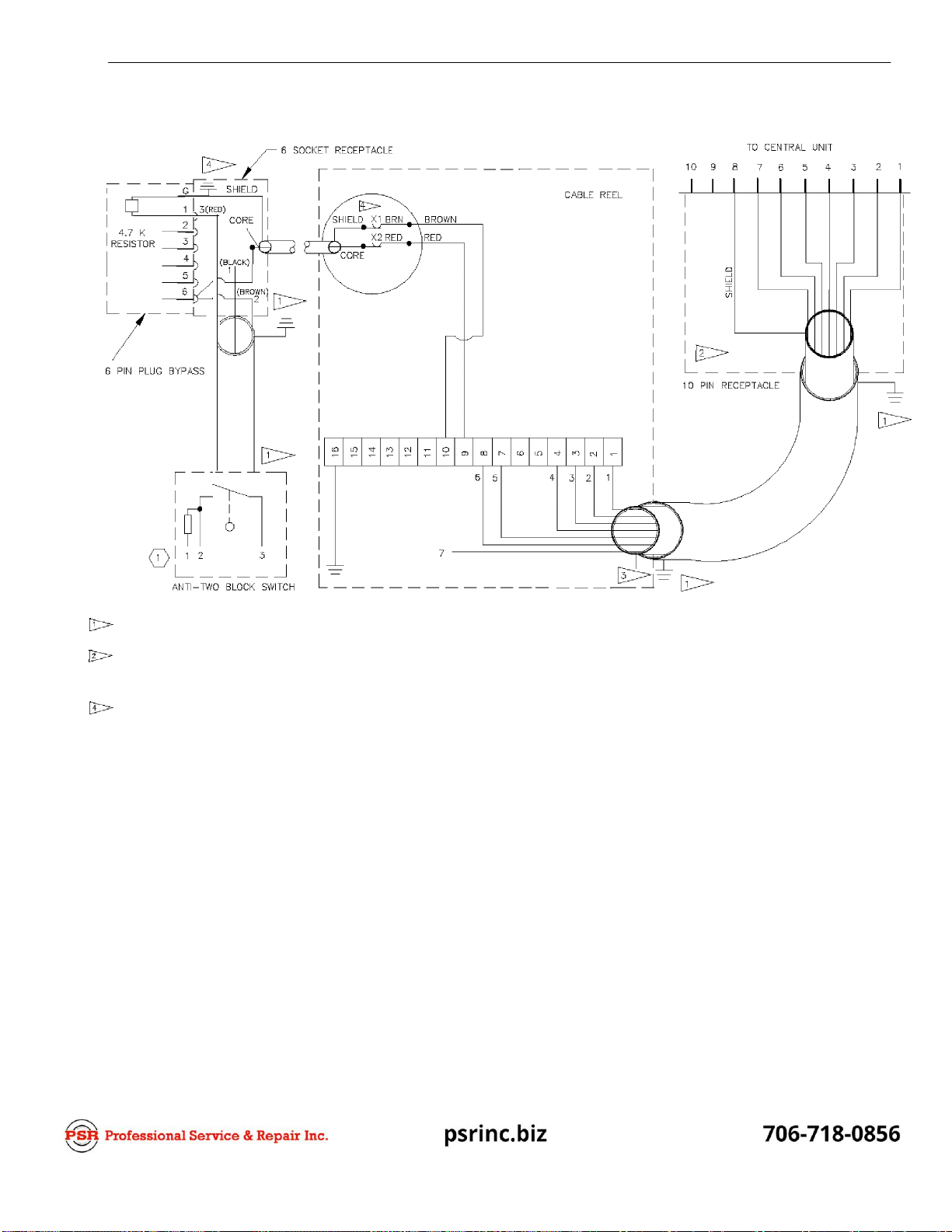

DRAWING 4. 031-300-060-653 A2B CONSOLE INSTALLATION KIT - ELECTRICAL

DIAGRAM..................................................................................................................................12

DRAWING 5. 031-300-100-654 A2B MAIN BOOM INSTALLATION KIT - ELECTRICAL

DIAGRAM..................................................................................................................................13

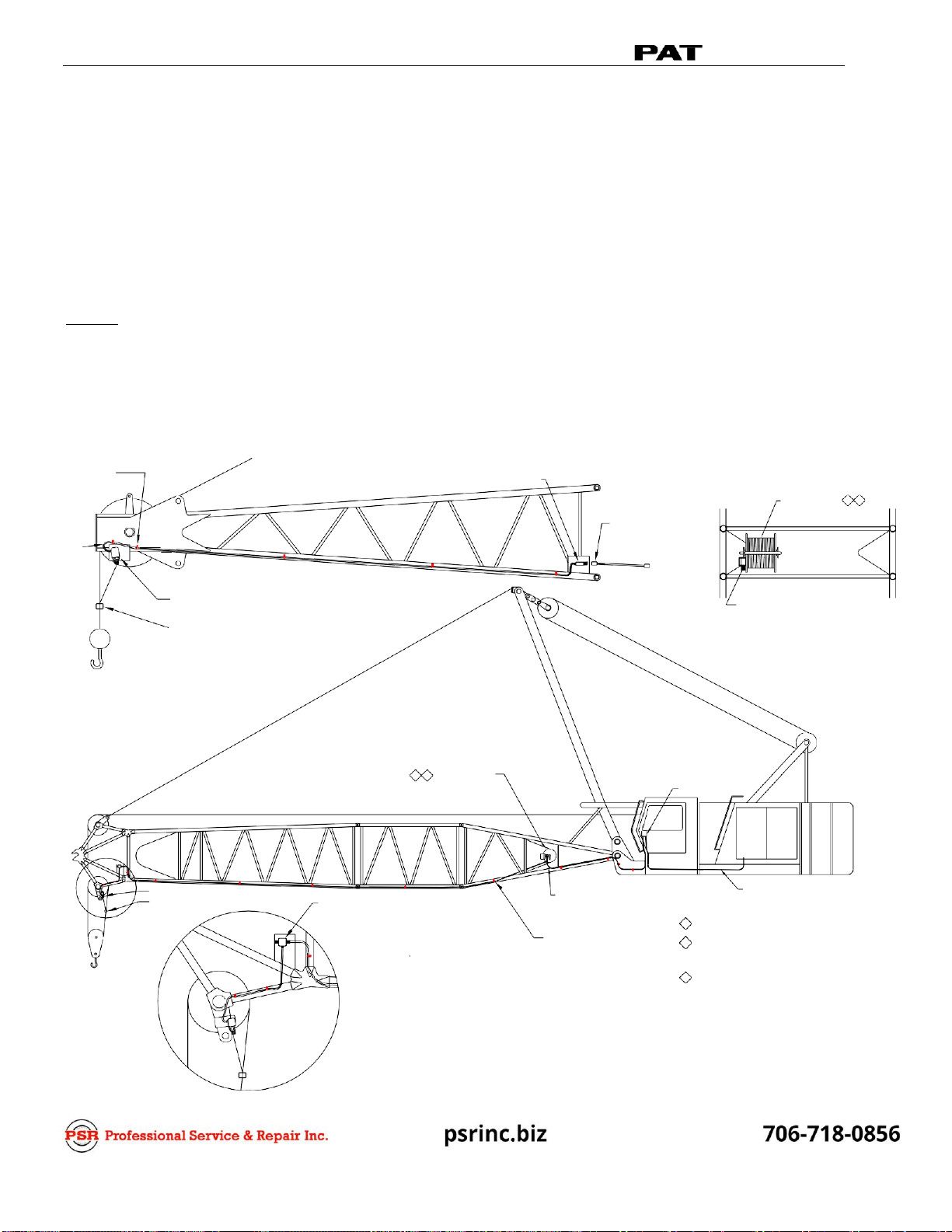

INSTALLATION, LATTICE CRANE........................................................................................14

DRAWING 6. 031-300-101-224 KIT, A2B MAIN BOOM LATTICE RETROFIT - PARTS LIST....14

031-300-101-225 KIT, A2B JIB LATTICE RETROFIT - PARTS LIST.........................................14

DRAWING 7. 031-300-101-224 KIT, A2B MAIN BOOM LATTICE RETROFIT - ELECTRICAL

DIAGRAM AND 031-300-101-225 KIT, A2B JIB LATTICE RETROFIT - ELECTRICAL

DIAGRAM..................................................................................................................................15

DRAWING 8. CONSOLE, A2B, W/LOCKOUT KEY SWITCH PARTS LIST................................16

DRAWING 9. 006-820-006-002 CABLE REEL, KT200 PARTS LIST..........................................17

LENGTH CABLEREPLACEMENT PROCEDURE .................................................................18

SLIP RINGREPLACEMENT PROCEDURE...........................................................................19

5

TROUBLESHOOTING ..............................................................................................................20

ANTI-TWO-BLOCK PROBLEM..............................................................................................20

ANTI-TWO-BLOCK THEORY..........................................................................................................................23

INSTALLATION, OPERATOR’S & TROUBLESHOOTING MANUAL

ANTI-TWO-BLOCK

GENERAL INFORMATION 1

1.

GENERAL INFORMATION

The PAT Anti–Two-block System has been designed to warn the crane operator of a two-blocking

condition of the crane. If a two-blocking condition is approached, the system will warn the operator by

sounding an audible alarm, lighting a warning light and locking out those functions which may

aggravate the crane's condition, whenever applicable.

NOTE: The term "two-block" is a crane term that refers to a condition when the load handling device

comes in contact with the boom head. This condition, if not prevented, may cause the wire rope to

break, allowing the load to fall. Either raising the load into the boom head, or telescoping the boom

without paying out hoist line can cause a "two- block" condition.

2.

WARNINGS

The PAT Anti-Two- Block System is an operational aid, which warns a crane operator of approaching

two-block conditions, which could cause damage to equipment and personal injury.

This device is not, and shall not be a substitute for good, sound operator judgment, experience and

use of accepted safe crane operating procedures.

The responsibility for the safe operation of the crane remains with the crane operator who shall ensure

that all warnings and instructions supplied are fully understood and observed.

Prior to operating the crane, the operator must carefully and thoroughly read and understand the

information in this manual to ensure that he or she knows the operation and limitations of the system

and the crane.

Proper functioning is dependent upon proper daily inspection and observations of the operating

instructions set forth in this manual. Refer to Section 4 of this manual.

3.

OPERATION

SYSTEM DESCRIPTION

The PAT Anti-Two-block System consists of an operating console, a cable reel, two-block switches

and all applicable wiring.

The anti-two-block switch(es) is (are) mounted at the head of the boom and boom extensions if

available. When the hook block contacts the weight, which means a two-block condition is

approaching, the hoist limit switch contacts open sending a signal that locks out the hoist up, boom up,

and tele out functions.

The cable reel, which is mounted on the boom base section, serves as an electrical conductor for the

anti-two-block switch signal.

The operating console is located in the operator's cab in front of the operator. This unit contains

different controls, which are described in the following picture.

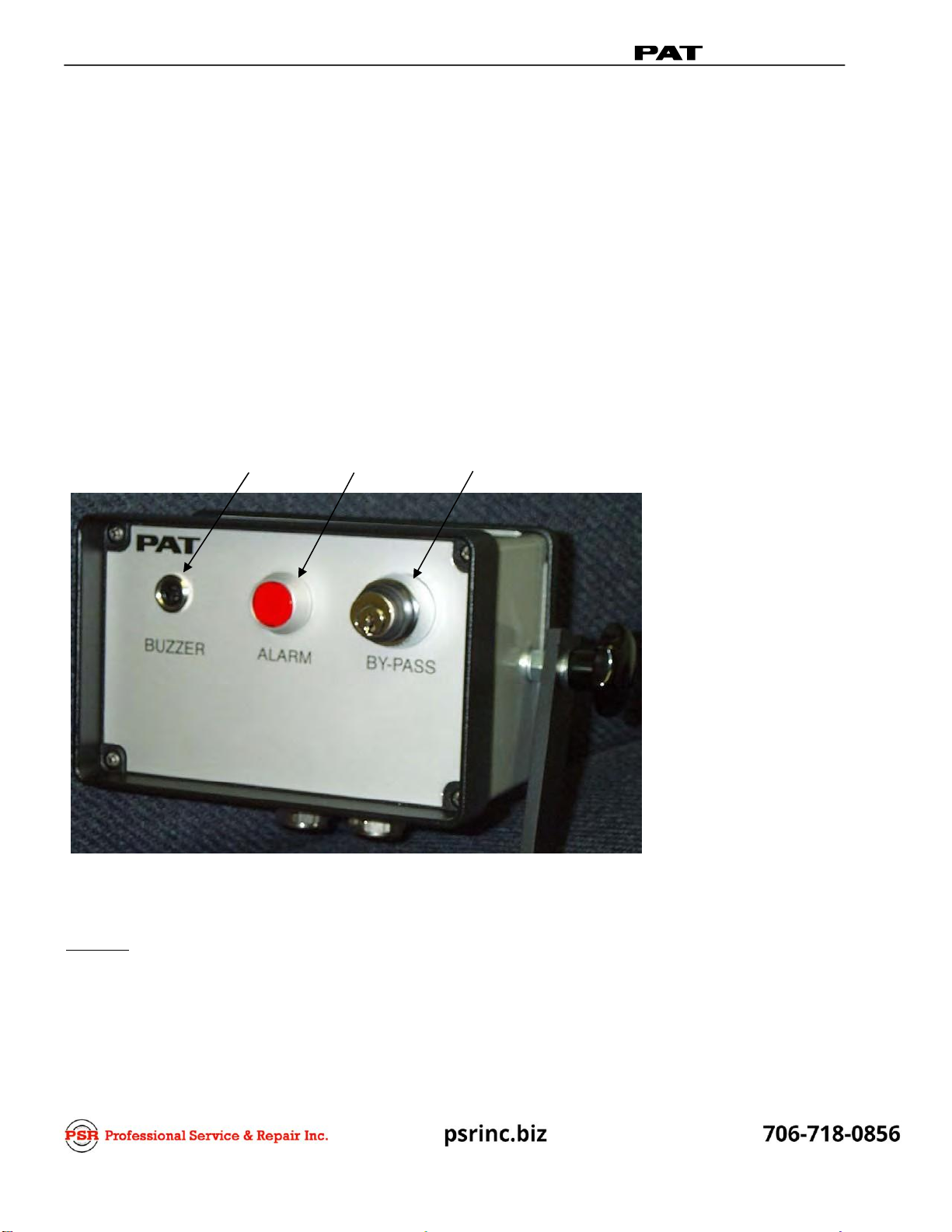

1.

Buzzer

2.

Alarm light button

3.

By-pass key switch

CONTROL

IDENTIFICATION

Figure 1 illustrates the controls of the PAT Anti-two-block System. The numbers of the illustration

correspond to the numbers in the following list, which describes the function of each control.

1. Buzzer: The BUZZER (1) is an audible alarm that sounds during an approaching two-block

condition of the crane. At the same time, the Anti-two-block Alarm Light (2) illuminates. The

following crane movements will be stopped concurrently; hoist up, telescope out and boom down.

(Whenever applicable) The audible alarm can be silenced temporarily by pushing the Alarm light

button (2).

2

INSTALLATION, OPERATOR’S & TROUBLESHOOTING MANUAL

ANTI-TWO-BLOCK

1

2

3

Since this switch deactivates the cut-off function of the anti-two-block system, the

following instructions shall be adhered to:

The by-pass key shall be used with discretion, because unwarranted use to

override the control lever lockout system can result in harm to the crane

and endanger property and/or person.

Never use the by-pass key to either overload or operate the crane in a

range that is not permissible.

PRE-OPERATION INSPECTION 3

2. Anti-Two-block Alarm Light and Alarm Stop Button: The ALARM LIGHT BUTTON serves a

dual purpose. First, a red warning light illuminates when the anti-two-block limit switch contact

opens. This indicates that a two-blocking condition is approaching. At the same time, the BUZZER

(1)

will sound and the following crane movements will be stopped concurrently: hoist up, telescope

out and boom down. (Whenever applicable) Second, it acts as an alarm stop button, which allows

the buzzer to be silenced temporarily.

3. By-Pass Key Switch: The BY-PASS KEY SWITCH (3) can deactivate the cut off function of the

anti-two-block momentarily to allow the crane operator to override the control lever lockout. This

function can only be engaged by using the matching key. The BY-PASS SWITCH has 2 positions,

which are more specifically described as follows:

The neutral position is engaged when the plunger is out and the key can be removed, as

shown below. In this position, the by-pass key switch does not influence the anti-two-block

control lever lockout.

This position bypasses the anti-two-block control lever lockout. This function can only be

engaged by using the matching key. In this position, the cut off function of the system is

deactivated. To activate the switch, the key has to be turned clockwise for about 45 degrees

and plunger push in, then turned back to the middle position to lock it in place (as shown

below). After activating the by-pass key switch, the alarm light will constantly blink, indicating

that the cutoff function has been deactivated. During this operation, with the anti-two-block

switch activated, the alarm light will blink with a higher frequency. The BUZZER (1) for

approaching two-block conditions will be illuminated at all times.

Failure to re-position the anti-two-block switch weight will prevent the system from functioning

properly. No weight shall be on the main hoist anti-two-block switch when the boom extension

is being used.

PRE-OPERATION INSPECTION

Prior to operating the crane, the following checks must be made:

1.

Check the cabling connections to the various parts of the system for physical damage.

2.

Check the spring-loaded cable reel to ensure it is free to rotate, has proper tension and is spooled

properly.

3.

Check the anti-two-block switches and weights for freedom of movement.

4.

Check the anti-two-block switch weight for proper installation on the hoist load line. The hoist line

runs through the A2B weight. With even parts of hoisting line, the weight shall be attached to the

dead-end line. With odd parts of hoisting line, the weight shall be attached to the line of lowest

speed.

5.

Check the A2B conditions for main/auxiliary hoist operation with the following instructions:

1)

If the crane works with only the main boom, the by-pass plug must be installed in the main

boom junction box.

2)

If the crane works with an extension:

a)

If the boom extension is not in the operating position, the by-pass plug must be installed in

the main boom junction box. The weight shall be installed on the main hoist anti-two-block

switch.

b)

If the boom extension is in the operating position and the load line is being used on the main

boom, the connecting cable must be installed between the junction boxes on the main boom

and extension. Weights must also be attached to the anti-two-block switches on both the

main boom and boom extension.

c)

If the boom extension is in the operating position and no load line is being used on main

boom, to prevent injury or damage to equipment, the weight shall be removed from main

boom switch. In that case the anti-two-block switch has to be locked with the red Anti-two-

block Retainer (See number 6 in this section).

4

INSTALLATION, OPERATOR’S & TROUBLESHOOTING MANUAL

ANTI-TWO-BLOCK

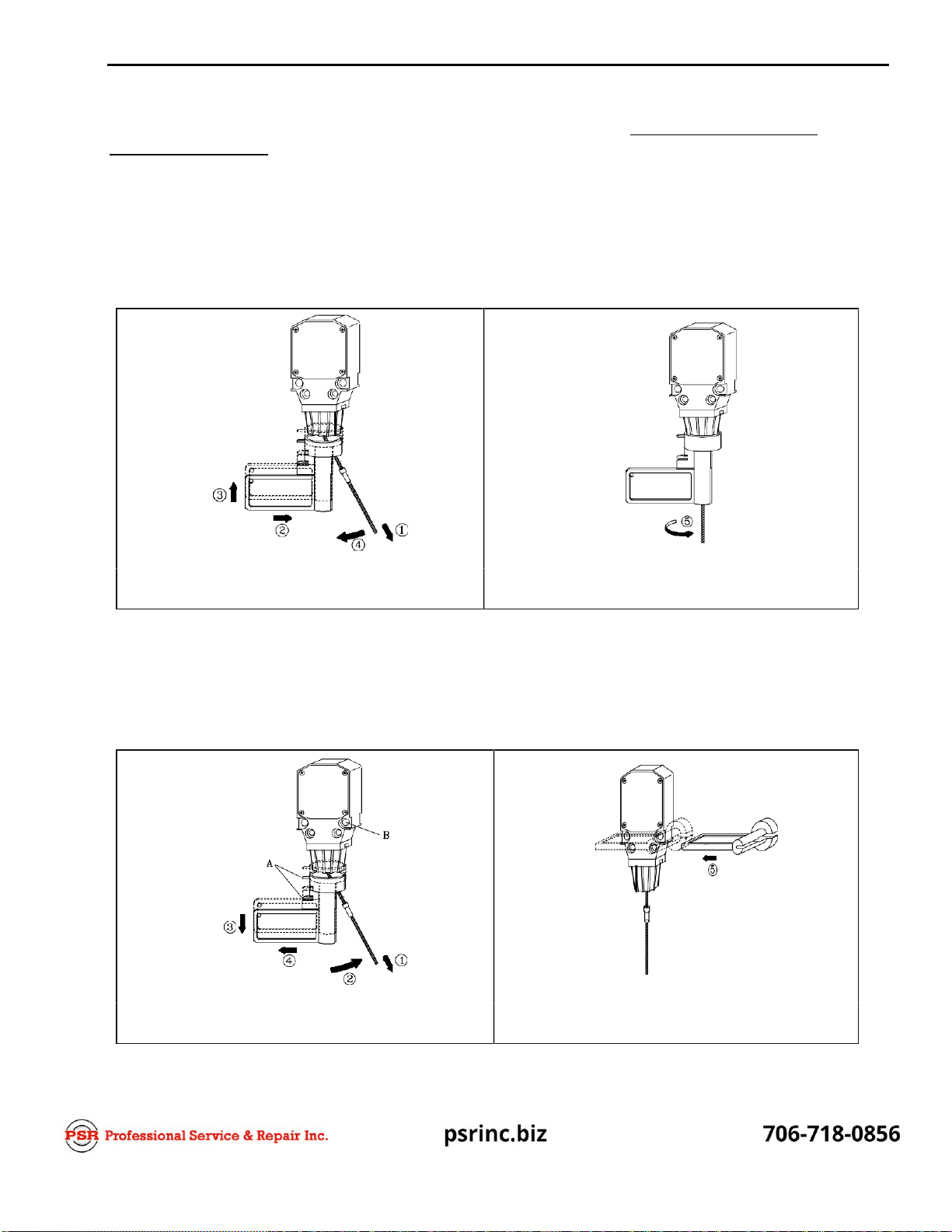

Fig. 1: Setting of Anti-two-block Retainer in

Locking Position

Fig. 2: Retainer in Locking Position

PRE-OPERATION INSPECTION 5

6.

Check the installation of the A2B retainer when applicable. - See Numbers 4 and 5 of Pre-

Operation Inspection, above.

Installation of Anti-two-block Retainer in Locking Position (Figures 1 and 2)

1.

Pull the cable out of the switch and bend back parallel to the boom and hold .

2.

Slide the retainer from left side with its slot over the cable between the crimped stop and the switch

. Push it firmly straight onto the cable guide of the Anti-two-block switch .

3.

Straighten the cable completely into the slot and release the cable.

4.

Turn the flag of the retainer for the operator’s best visibility. .

Removal and Storage of Anti-two-block Retainer (Figures. 3 and 4)

1.

Pull the cable out of the switch and bend back parallel to the boom and hold .

2.

Move the retainer down and then left to remove it from the Anti-two-block switch. Release the

cable.

3.

For storage, slide the retainer from the right side over the Anti-two-block switch until the clips (A)

lock into the holes (B).

Fig. 3: Removal of the Anti-two-block

Retainer

Fig. 4: Retainer in Storage Position

The following tests must be performed carefully to prevent personal injury or damage to the

machine. Proper system functioning requires successful completion of these tests before

operating the machine.

If the operator cannot clearly see the hook block approaching the boom head, an assistant

must watch the hook block.

The operator should be prepared to stop the machine immediately, if the system fails to

function properly by lighting the red warning light and /or sounding the audible alarm.

OPERATIONAL TESTS

The operation test will test and verify the anti-two- block switch(es)is (are) functioning properly. This

test should be completed periodically or any time there is an indication of uncertainty for operation.

1.

Start the crane in accordance with crane operator’s manual.

2.

Verify that the anti-two-block indicator and audible alarm function properly by manually lifting the

weight attached to the A2B switches on the crane. When the weight is lifted, the audible alarm

should sound, and the anti-two-block alarm light should light. (See SAE J1305 for two-block

warning and limit system operation)

3.

Slowly raise the main boom hook block to bring it into contact with the A2B switch weight.

NOTE: If the operator cannot see the load handling device approaching the boom nose, he shall have

an assistant (signal person) watch the load handling device. The operator shall be prepared to

stop the machine immediately if the system fails to function properly by lighting the red

warning light, sounding the audible alarm and locking the hoist up function.

When the hook block contacts the weight, the red anti-two-block indicator should light and the

audible alarm should sound. NOTE: The hoist up function of the crane will be disabled. Lower the

hook block to eliminate the two-block condition.

If the light and audible alarm do not function as described and the crane movements are not

stopped, the system is not working properly. The malfunction must be corrected before

operating the crane.

6

INSTALLATION, OPERATOR’S & TROUBLESHOOTING MANUAL

ANTI-TWO-BLOCK

INSTALLATION 7

4

INSTALLATION

SYSTEM KITS

This Installation Manual shows the approximate location of components and wiring diagrams required

for system operation. This manual has two different system component and wiring diagrams;

therefore, use the drawings that match your system, as shown below:

1.

031-300-100-432 SYSTEM, A2B HYDRAULICMAINBOOM

Component Item Qty Component Description

031-300-100-653 1.0 KIT, A2B CONSOLE

031-300-100-654 1.0 KIT, A2B MAINBOOM

031-300-100-443 1.0 KIT, A2B MAINBOOM MOUNTING (15R)

031-300-100-201 1.0 MANUAL, A2B SYSTEM RETROFIT INSTALLATION

2.

A2B LATTICE MAIN & EXT BOOM KITS

Component Item Qty Component Description

031-300-101-224 1.0 KIT, A2B MAIN BOOM LATTICE RETROFIT

031-300-101-225 1.0 KIT, A2B JIB LATTICE RETROFIT

031-300-100-201 1.0 MANUAL, A2B SYSTEM RETROFIT INSTALLATION

NOTE: Prior to starting the installation, it is advised to review the drawings and define the

component locations on the crane. The Anti-two-block System must be tested after completing

installation. Complete Section 3.3 Pre-Operation Inspection and Section 3.4 Operational Tests

in the Operator’s portion of this manual, Section 3. Operation.

3) Prior to operating the crane, the operator must carefully read and understand the information in

Section 3. Operation, in order to know the operation and limitations of the Anti-two-block System.

INSTALLATION, HYDRAULIC CRANE

Select the correct section for your crane and use the anti-two-block system drawings for component

installation and wiring system.

031-300-100-432 SYSTEM, A2B HYDRAULIC MAINBOOM

Drawing 1. 031-300-060-653 A2B Console Installation Kit - Parts List

Drawing 2. 031-300-100-654 A2B Main Boom Installation Kit - Parts List

Drawing 3. 031-300-100-443 A2B Mounting Kit - Parts List

Drawing 4. 031-300-060-653 A2B Console Installation Kit - Electrical Diagram

Drawing 5. 031-300-100-654 A2B Main Boom Installation Kit - Electrical Diagram

Optional jib kits are not shown on parts list. (The additional components are available upon request.)

NOTE: CONTACT CRANE MANUFACTURER FOR WELDING INSTRUCTIONS PRIOR TO

WELDING ON BOOM.

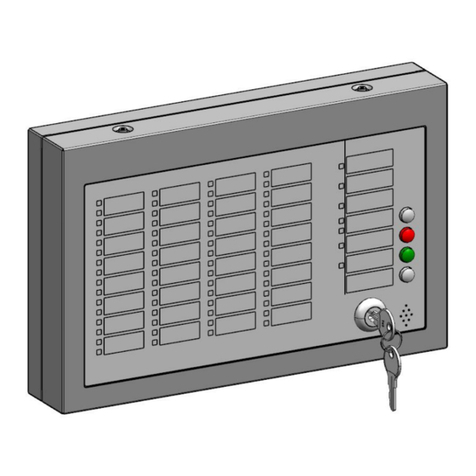

DRAWING 1. 031-300-060-653 A2B CONSOLE INSTALLATION KIT - PARTS LIST

VIEWOFCONSOLE

MOUNTEDINCAB

P A T

2,3,4,5

1

13 1

14

15

16 9

10

11

12

TO PLUG

AT BOOM BASE

CLEANELECTRICALCONTACTSAND

CONNECTORSOFALLFOREIGN

MATERIAL SUCH AS GREASE, OIL,

ANDDIRTBEFORECONNECTING.

CONTACTCRANEMANUFACTURERFORWELDINGINSTRUCTION

PRIORTOWELDINGONTHEBOOM.

7,8,9,10,11

TO CONSOLE

16 IN CAB

NO. PART NO. QTY DESCRIPTION

01 050-000-060-100 1 A2B CONSOLE, 12VW/ LOCKOUT KEYSWITCH

02 000-301-022-100 1 PLUG, 10 PIN

03 000-301-025-102 1 INSERT, 10 PINFEMALE

04 000-214-261-613 1 REDUCER, PG16-13.5

05 021-441-131-013 1 STRAIN RELIEF, PG13.5 W/ RED/WHTINSERT

06 000-610-020-371 5 TIE WRAP,VINYL

07 000-325-040-916 5 CABLE CLAMP, 9/16"

08 002-350-207-250 5 STUD, 1/4-20 X 7/8WELD

09 000-207-010-070 7 FLAT WASHER, 1/4

10 000-208-040-070 7 LOCK WASHER, 1/4

11 002-060-100-705 7 NUT, 1/4-20 HEX

12 002-051-107-255 2 SCREW, 1/4-20 X 1 HEXHEAD

13 031-010-100-153 2 TERMINAL, MALE .250 DC/MI 14-16 AWG

14 031-010-100-154 4 TERMINAL, FEMALE .250 DC/FI 14-16AWG

15 031-300-100-146 14' CABLE, 4 X 1.5S.S.

16 031-300-100-148 22' CABLE, 7 X 0.5D.S.

8

INSTALLATION, OPERATOR’S & TROUBLESHOOTING MANUAL

ANTI-TWO-BLOCK

1

8,9

0,11,12

20,21

21,22

42,43,44,45

13,14,15,1

5. 5"TO

P AT

26

1 1 /2

TYP.

SPAC

AT 55

18

2-7/8

30

FRONT

EAR

17

PDSITIO N *H E BASE SEC*I0 N ROLLER GUI DE, A DIST ANCE FRO M

VIEW A—A.

P05%ON HE?H?OF I0E,BA5, ,CTO’, R0,iLE„, DDE ?0?H,I

REEL. THE IABLE’WlLL HAYE AN ANGLE OF APPROXlPATELT 5’

INSTALLATION, HYDRAULIC CRANE 9

DRAWING 1. 031-300-060-654 A2B MAIN BOOM INSTALLATION KIT - PARTS LIST

NO. PART NO. QTY DESCRIPTION

01 068-000-050-078 4 HOOK BOLT, 3/8-16 X4

02 068-000-050-077 2 HOOK BOLT, 3/8-16 X 23/4

03 000-207-010-105 12 FLAT WASHER, 3/8

04 000-208-040-100 12 LOCK WASHER,3/8

05 002-060-101-005 8 NUT, 3/8-16 HEX

06 002-051-110-255 4 SCREW, 3/8-16 X 1 HEXHEAD

07 002-350-207-255 15 STUD, 1/4-20 X 1WELD

08 002-060-100-705 15 NUT, 1/4-20 HEX

09 000-208-040-070 15 LOCK WASHER,1/4

10 000-207-010-070 15 FLAT WASHER, 1/4

11 000-301-023-100 1 RECEPTACLE, 10 PIN

12 004-000-050-011 1 MOUNTING PLATE, 10 PINRECEPTACLE

13 002-053-904-127 8 SCREW, #10-24 X 1/2 ROUNDHEAD

14 000-208-040-053 8 LOCK WASHER, #10

15 000-301-025-101 1 INSERT, 10 PINMALE

16 000-214-340-016 2 HOLE PLUG, PG16

17 006-820-006-002 1 CABLE REEL, KT200STANDARD

18 031-300-100-148 20' CABLE, 7 X 0.5D.S.

19

031-002-100-053 1 A2B RETAINER FLAG W/ METALINSERT

20

031-300-100-269 1 DECAL "WARNING" A2BSWITCH

21

031-002-060-011 1 A2B SWITCH, (NEW STYLE) W/CRIMP

22 031-300-100-105 2 SCREW, 5/16-18 X 1 1/2 SOCKET CAP,STAINLESS

23 031-000-050-004 1 PLATE, A2B SWITCH, ADAPTER (PRIMERED)

24 002-070-100-805 2 FLAT WASHER, 5/16

25 000-208-040-080 4 LOCK WASHER, 5/16

26 000-051-106-185 2 SCREW, 5/16-18 X 3/4"HEX

27 031-300-100-110 10' CONDUIT, 1/4" BLACKFLEX

28 000-325-040-916 12 CABLE CLAMP, 9/16"

29 004-000-050-010 1 MOUNTING PLATE, 6 PINRECEPTACLE

30 000-301-022-296 1 RECEPTACLE, 6 PIN

31 000-301-022-060 1 PLUG, 6 PIN

32 000-301-025-061 1 INSERT, 6-PIN MALE

33 000-301-025-062 1 INSERT, 6-PIN FEMALE

34 000-214-340-013 1 HOLE PLUG, PG13.5

35 000-214-261-609 2 REDUCER, PG16-9

36

021-441-060-409 1 STRAIN RELIEF, PG9 YELLOW/WHITE

37

068-000-050-072 1 PLATE, CABLE REEL MOUNTING(PRIMERED)

38

021-441-090-909 1 STRAIN RELIEF, PG9, 3mm WHITE

39 000-214-261-613 1 REDUCER, PG16-13.5

40

031-004-100-028 4 CABLE GUIDE, SMALL,MAINBOOM

41

031-004-100-033 1 CABLE GUIDE, LARGE, MAINBOOM

42 000-610-020-371 5 TIE WRAP, VINYL, 1/4 X13"

43 000-401-024-470 1 RESISTOR, 4.7K

44 021-441-131-013 2 STRAIN RELIEF, PG12.8,RED/WHITE

45 031-300-100-064 4 BUSHING, FOR HOOKBOLT

46 031-002-100-048 1 LANYARD, RED

47 031-300-100-037 1 CHAIN CONNECTOR, QUICK LINK, 27/16"

48 003-100-210-012 1 WEIGHT & CHAIN, A2B W/SHACKLE

10

INSTALLATION, OPERATOR’S & TROUBLESHOOTING MANUAL

ANTI-TWO-BLOCK

5

INSTALLATION, HYDRAULIC CRANE 11

DRAWING 3. 031-300-100-443 A2B MOUNTING KIT - PARTS LIST APPROX.

1 2 2 60

3

A

P A T

1 1 1 A

4

5

1 1/ 2

TYP.

5

1

3

ROLLERGUIDESONBASESECTION

1 BECENTEREDONCABLEDRUM,

INGGUIDESTOFORMSTRAIGHT

TODEADENDON

WHENOPTIONALSWINGAWAY

SIONORROOSTERSHEAVEIS NOT

USE.STOWEXTENSIONCORDAND

STALLJUMPERPLUGIN BOOMNOSE

RECEPTACLE. WHEN OPTIONAL

AWAYEXTENSIONORROOSTER

IS IN USE,REMOVEANDSTOW

PLUG.INSTALLJUMPERCORD

BOOMNOSERECEPTACLEAND

AWAYEXTENSIONORROOSTER

RECEPTACLE.

POSITIONHEIGHTOFROLLERGUIDE

OBTAINCABLEREELLINEPATH

IS PARALLELTOTOPSURFACEOF

SECTIONS.

CUTA2BSWITCHCABLEAND

TODESIRED

CLEANELECTRICALCONTACTS

CONNECTORSOFALLFOREIGN

MATERIALSUCH AS GREASE,

ANDDIRTBEFORE

CONTACTCRANEMANUFACTUREFORWELDING

PRIORTOWELDINGONTHE

3

VIEWA- A

NO. PART NO. QTY DESCRIPTION

01 031-004-050-037 1 BRACKET, CABLE GUIDE ANGLE(7.5')

02 031-004-050-047 4 BRACKET, CABLE GUIDE ANGLE (7.5' X8")

03 031-004-050-057 1 BRACKET, LENGTH CABLE 1" ID X 1/8"WL X 8 1/2"

2

4

3

12 INSTALLATION, OPERATOR’S & TROUBLESHOOTING MANUAL ANTI-TWO-BLOCK

DRAWING 4. 031-300-060-653 A2B CONSOLE INSTALLATION KIT - ELECTRICAL DIAGRAM

INNER SHIELD

(Is)

INSULATED

AND CONNECT E D AS SHOWN.

OUTER SHIELD GROUNDED Y/ITH

COMPONE NT STRAIN RELIEF

CRANE ELECTRIC CONNECTION —

COMPONENTS ARE 0PT|0NAL AND

NOT SUPPLIED BT PAT.

RE*ER TO CRANE ELECTRIC

SCHEMATICS.

EACH 30LENQID VALVE 0R

MAC N ET DEVICE TQ BE INSTALLS D

Y/ITH DI0DE IN 4003....IN4007 AS

SH0Y/N.

Y/IRE ENDS INSULATED AND NOT

CONNECTED (WIRE 1—4, & 7).

' "10AMP

b!rusE

A2B—CONSOLE

050 000 060 00

19

i0 PIN PLUG

TO MAN BOOM REAR

INSTALLATION, HYDRAULIC CRANE 13

DRAWING 5. 031-300-100-654 A2B MAIN BOOM INSTALLATION KIT - ELECTRICAL DIAGRAM

N Q TES :

OU TER SH

I

ELD GROUNDED A* STRAI N

RELIEF C 0 N N EC*OR

I

NN

ER

SH

I

ELD

INSULATED

AND CON

N

EC*ED

AS S H0WN

INNER SHIELD CUT OFF AND TAPED

OUTER SH OLD NSU LACED AND CON N EC*LD

AS SHOWN

SWITC H PREWIRE D AND PO*TED

WELD STUD W/

CONNECT PLUG FROM SWITCH

TO THE JUMPER CABLE

CABLE REEL 1 2

CONDUIT

031-300-060-051

JUMPER CABLE FROM

JIB TO MAIN BOOM

BOOM TIP

BOOM BASE

A2B SWITCH ASSEMBLY

031-300-100-458

A2B SWITCH WEIGHT

CONNECT PLUG FOR CABLE

FROM A2B CONSOLE

TOP VIEW

031-300-101-225 A2B JIB KIT

1 2 CABLE REEL

031-300-060-049

A2B CONSOLE

A2B SWITCH 031-002-060-011

A2B SWITCH WEIGHT

4 CONDUCTOR CABLE

FOR CRANE POWER

JUNCTION BOX

531-300-100-112

2 CONDUCTOR CABLE

ASSEMBLY TO CABLE REEL

031-300-060-050

WELD STUD W/

9/16" CABLE CLAMP

031-300-101-224 A2B MAIN BOOM KIT

NOTES:

1

ALLOW AMPLE CABLE LOOP TO COVER

ALL MAST ANGLES.

2

TO CONNECT CABLE REEL TO MAIN BOOM NOSE;

UNROLL CABLE FROM CABLE REEL AND SCREW

2 PIN RECEPTACLE PLUG INTO THE MAIN BOOM

NOSE JUNCTION BOX.

3

REFER TO OPERATOR'S HANDBOOK FOR PROPER

USE OF A2B SWITCH WEIGHT AND RETAINER FLAG.

INSTALLATION, LATTICE CRANE

SYSTEM, A2B LATTICE MAIN & EXT BOOM KITS

Drawing 6. 031-300-101-224 Kit, A2B Main Boom Lattice Retrofit - Parts List and

031-300-101-225 Kit, A2B Jib Lattice Retrofit - Parts List

Drawing 7. 031-300-101-224 Kit, A2B Main Boom Lattice Retrofit - Electrical Diagram

and 031-300-101-225 Kit, A2B Jib Lattice Retrofit - Electrical Diagram

Optional jib kits are shown on parts list (the additional components available upon request)

NOTE: CONTACT CRANE MANUFACTURER FOR WELDING INSTRUCTION PRIOR TO WELDING

ON BOOM.

DRAWING 6. 031-300-101-224 KIT, A2B MAIN BOOM LATTICE RETROFIT - PARTS LIST

031-300-101-225 KIT, A2B JIB LATTICE RETROFIT - PARTS LIST

14

INSTALLATION, OPERATOR’S & TROUBLESHOOTING MANUAL

ANTI-TWO-BLOCK

This manual suits for next models

6

Table of contents