PSV groupe DRC114 User manual

1

F

FL

LO

OO

OR

R

S

ST

TA

AN

ND

DI

IN

NG

G

M

MI

IN

NC

CE

ER

R

D

DR

RC

C1

11

14

4

U

Us

se

er

r

G

Gu

ui

id

de

e

Usine du berre au Loup –RD147 –BP20 –95420 Genainville –France

Marques, brevets et modèles déposés France et étranger. R.C.S. Pontoise B 642 033443

« Original manual »

2

Certificate of Conformity to rules of the European Community

The manufacturer hereby GROUPE PSV, BP20 95420 GENAINVILLE

NEW EQUIPMENT COVERED BY FOLLOWING DIRECTIVES

MACHINE 2006 / 42 / CE

CEM 2014 / 30 /UE

BT 2014 / 35 / UE

MODELE : TRADITIONAL MINCER

TYPE : DRC114CS

SERIAL NUMBER :

M. Dominique VILLA

CEO

3

TABLE OF CONTENTS

1/ INTRODUCTION AND NORMALISATION ………………… p.4

2/ INSTALLATION AND ELECTRICAL CONNECTION …… p.5

3/ CHARACTERISTICS AND TECHNICAL SHEET………. p.6

4/ DESCRIPTION ……………………………………………... p.8

A/ INSTALLING THE BODY ………………………………… p.8

B/ PLATES AND KNIVES MOUNTING ………..……… p.9

2/ SYSTEM WITH 3 CUTTING ELEMENTS……………… p.10

3/ SYSTEM WITH 5 CUTTING ELEMENTS……………. p.11

C/ PRECAUTIONS………………………………………. p.12

1/ MOUNTING & MAINTENANCE OF UNGER SYSTEM p.12

2/ UTILISATION DES BOUTONS DE COMMANDE p.13

3/ PRODUCT PUSHER USING ……………………………. p.14

5/ MAINTENANCE…………………………………………........ p.15

A/ CLEANNING OF THE MACHINE…. ..……………….. p.15

B/ PRELIMINARY CLEANNING ………………………… p.15

C/ DISINFECTION…………………. ……………………. p.15

D/ RINSE… …………………………………………………. p.16

E/ MAINTENANCE …………………………………………... p.16

6/ WARNING…….…………………………………………… p.17

7/ ACCESSORIES ……………………………………………… p.17

8/ AFTER SALES SERVICE ………………………………….. p.17

9/ WARRANTY CONDITIONS…. …………………………… p.18

10/ NOMENCLATURE DRC 114………………………….. p.19/20

11/ EXPLODED VIEW DRC 114 …………………………... p.21/22/23/24

12/ ELECTRICAL SCHEME …………………………………. p. 25

4

1/ INTRODUCTION

The mincer DRC 114 can mince all kinds of meat for the production of

hamburgers, meatballs, sausage…

The mincer can be equipped with 3 or 5 cutting elements UNGER.

(See on page 10/11)

The mincer 114 is equipped of one or two knife double side with removable blades.

NORMALISATION

These devices meet the requirements of the decrees and safety standards.

General hygiene and safety laid down in Articles 84 to R233-R233-106, introduced

in the Labour Decree No. 80543 of July 15, 1980.

French standard NF U66-062, Machine chopping meat, integrated

prevention.

The control devices and signage, exhibit a degree of protection IP54 as defined in

standard NF 20-010.

All devices present a degree of protection IP245.

Continuous sound pressure level equivalent to the Workstation measured according

to standard NF S31 124 P <70 dB (A) empty and loaded

The hand-protection plate is mandatory and should never be disconnected from

the board.

5

2/ INSTALLATION

Place the machine on a stable and solid floor

ELECTRICAL CONNECTION

Electrical plug in must be preformed by qualified personnel and be conduced in

compliance with safety standards.

The line of the power supply must be carried out using a cable section adapted to the

power of the machine and must include three phase conductors and a grounding

conductor (voltage machine 400v, 50 Hz) or two phase conductors and a grounding

conductor (voltage machine 230v, 50 Hz) .

Electrical plug in must be protected by a circuit-breaker.

6

3/ CHARACTERISTICS

TECHNICAL SHEET DRC 114

TECHNICAL CHARACTERISTICS

DRC 114

Dimensions

1000 x 760 x 1250

Weight

129 kg

Packing dimensions

1200 X 800 X 1350

Débit théorique

900 Kg/h

Motor

5,5 CV / 4,1 KW

Tension

3 PHASES - 400v - 50 HZ

Gear box

PSV gear box

Cutting system

3 or 5 cutting elements UNGER

Standard equipment

1 knife, 1 plate Ø5, 1plate / knife

7

4/ DESCRIPTION

A/ BODY MOUNTING

Rotate the safety guard to place the body

Place the body in front of the machine

8

Fit the body in its seats (two blots through).

9

Tighten the two clamp handles setting the body on the machine

Make sure that the body is properly applied against the front

10

B/ MOUNTING PLATES AND KNIVES

1/ 3 CUTTING ELEMENTS SYSTEM (UNGER).

NOTE : DISCONNECT THE MACHINE OF THE ELECTRICAL RETE FOR THE

FOLLOWING OPERATIONS :

A- Insert the helix (2) inside the body (1) with a slight twisting motion for a good

engagement with the hex output shaft engine.

B- Mount the cutting plate (3).

C- Mount the knife (4).

D- Mout the plate (5).

E-Mount the ring (6).

F-Mount the nut (7).

IMPORTANT :

The mounting must be done in the order announced.

Do not mount the both body / helix and the cutting system in one time.

The mounting must be done following the steps.

11

2/ 5 ELEMENTS CUTTING SYSTEM (UNGER).

NOTE : DISCONNECT THE MACHINE OF THE ELECTRICAL RETE FOR THE

FOLLOWING OPERATIONS :

A- insert the helix (2) inside the body (1) with a slight twisting motion for a good

engagement with the hex output shaft engine.

B- mount the plate/knife (3).

C- mount the knife (4).

D- mount the plate (5).

E- mount the knife (6).

F- mount the plate (7).

G- mount the ring (8).

H- mount the nut (9).

IMPORTANT :

The mounting must be done in the order announced.

Do not mount the both body / helix and the cutting system in one time.

The mounting must be done following the steps.

12

C/ PRECAUTIONS

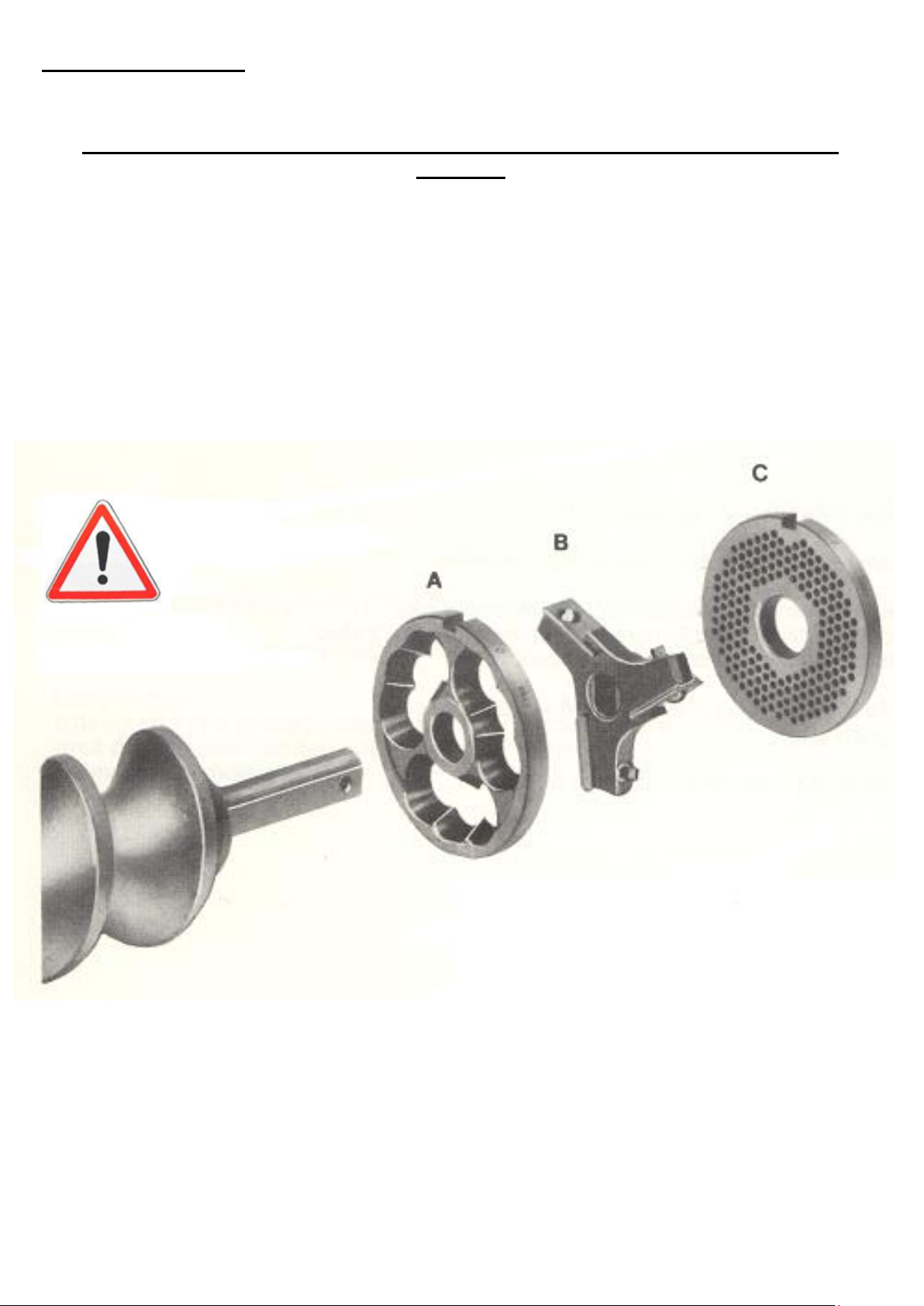

1/ PRECAUTIONS FOR THE MOUNTING AND MAINTENANCE OF UNGER

SYSTEM

Make sure that the system is mounted as shown below. Improper installation,

including upside down, causes breakage of plates and knives.

The plate knife must be perfectly aginst the face of the body.

The nut stainless steel machine should not be tightened significantly.

Change the blades before they are flush with the branches of knives.

To surface plates from wear. Plates prevent waste a perfect fit and cause rapid wear

of blades.

A- PLATE KNIFE

B- DOUBLE FACE KNIFE (shoulder outlet plate side)

C- HOLES PLATE

13

2/ USING THE PANEL

Pushing the GREEN button, the machine starts. The rotation of the

feed screw must be done in unclock sense.

The machine stops by pushing the RED button.

If the machine is blocked, push the BLACK button once.

The emergency stop must be used to stop the machine in case of

emergency. Using this button, it must be unlocked to restart the machine.

ON BUTTON

OFF BUTTON

REVERT

BUTTON

EMERGENCY

STOP

14

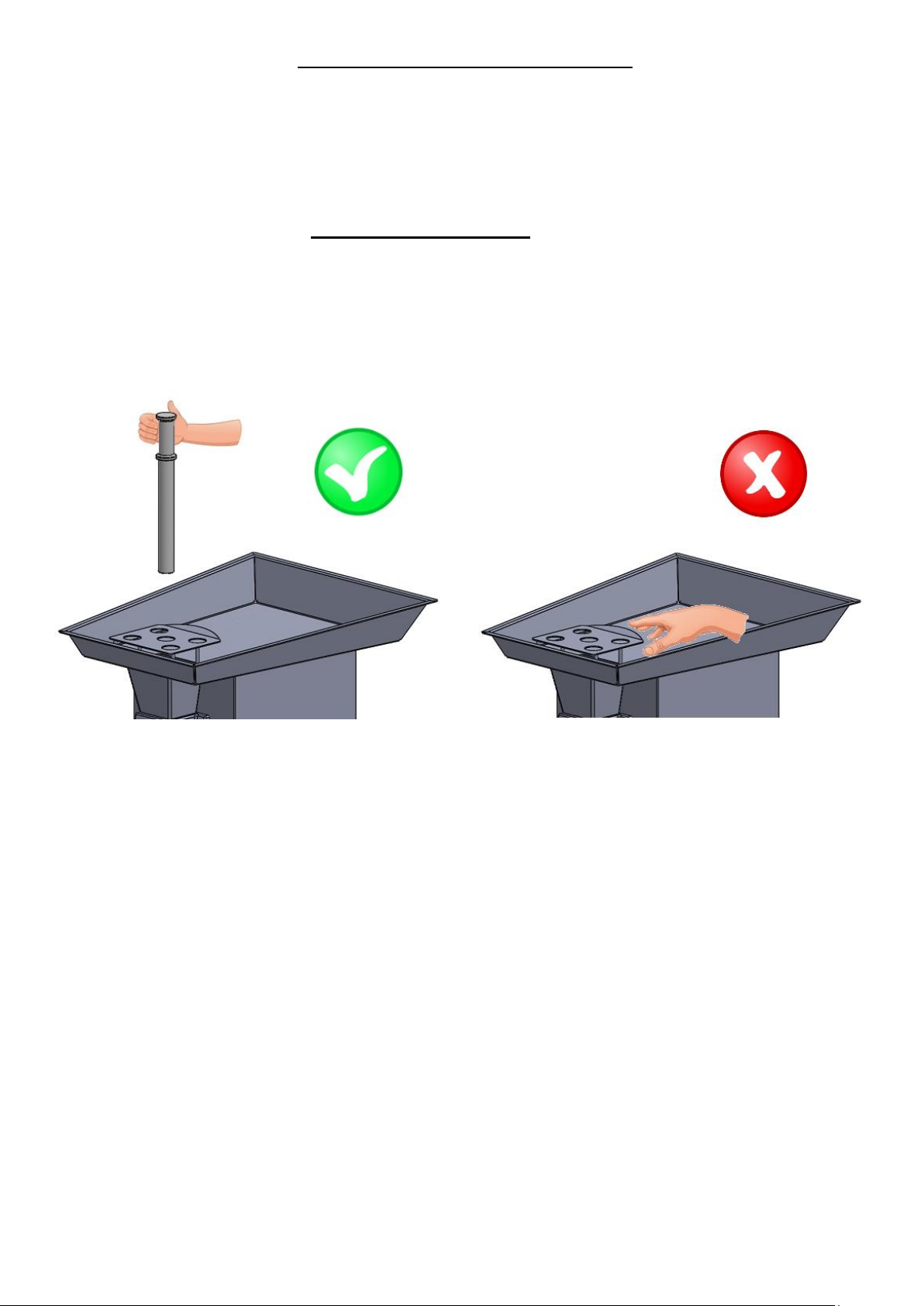

3/ USING THE PLASTIC FEEDER

The machine is delivered with a plastic feeder to push the meet in the feed screw.

Using the plastic feeder is extremely important, it is strictly forbidden to us the

hand to avoid any failures.

15

5/ MAINTENANCE

DISCONNECT BEFORE ANY INTERVENTION

A/ CLEANING OF THE MACHINE :

For obvious hygiene reasons, the machines for mince meat need to be cleaned often

and correctly. Machines must be maintained in perfect conditions, cleaned,

dismounted, disinfected two times per day.

For cutting elements cleaning, it is necessary to dismount the whole body/helix and

the cutting element in the same time to avoid any failures (and following the

standard NF EN 12331:2013).

We recommend the use of detergents and disinfecting products.

B/ PRELIMINARY CLEANING :

Remove visible dirt by brushing (body, feed screw, nut, plates and knives).

C/ DISINFECTION :

Immerse all removable parts in a bath of warm water (T° 45 à 55°C), with an

appropriate detergent.

For the meat plate and the body wash in warm water with the same detergent.

D/ RINCE :

Rinse the removable parts

Rinse the plate and the body

16

Do not immerse the device

Do not clean with high pressure jet

The brushes used must be cleaned with a detergent solution.

The chopper’s body does not require special maintenance. Just use a towel or

disposable paper moistened

Avoid using abrasive cleaners that will damage the steel. Sponges are

prohibited.

E/ MAINTENANCE :

Lock system must be controlled daily.

17

6/ WARNING

SECURITY PARTS :

En aucun cas la plaque protège-main située sur le plateau doit être déformée et à

fortiori enlevée ou dessoudée.

PROTECTION AGAINST THE RISKS OF FAILURES CAUSED BY

KNIVES :

There is a serious risk when the operator can move the fingers through the plates as

the knife rotates in contact with it.

When the holes have a diameter less than 4mm, the risk of introduction of the

fingers does not exist (CF NF E 09-010). It is the same for diameters between 4 and

8mm included, provided that the plate has a thickness of 5mm.

For holes diameters greater than 8mm or specially shaped opening (in beans for

example), it is necessary to develop a device which prevents access to the

dangerous part.

The safety guard in front of the machine has been developed for that case, in

conformity with EN 12331 : 2013 standard.

7/ ACCESSORIES

The device is delivered with a pestle in food and a 24 key for the body clamping.

8/ AFTER SALES SERVICE

After sales service must be done by our distributor :

Our distributor will take care of the machine’s installation and possible

restoration of your device

Our distributor will answer your enquiry of spare parts and accessories.

18

9/ WARRANTY CONDITIONS

En tant que fabricant, nous garantissons notre matériel un an contre tout vice de

fabrication, la facture faisant office de bon de garantie.

As a manufacturer, we guarantee one year for any manufacturing defect, the

invoice acting as a warranty.

IMPORTANT :

Electricals and electronics are excluded from the warranty.

Warranty limits :

The warranty applies only to the purchaser and not to third parties to which

the material could be resold.

Our guarantee is limited to replacement or repair free of parts found defective by us.

In this case, the material is returned to us prepaid.

The port and the workforce are in all cases be borne by our distributor.

All comments and not misuse by special instructions, changes, modifications, or

repairs outside the workshop of an authorized dealer, and the lack of identification

plate, resulting in the cancellation of the guarantee.

19

10/ NOMENCLATURE

NOMENCLATURE DRC 114 -

DESCRIPTIONS

REFERENCE

QTY / 114

PART

NUMBER

PLASTIC FEEDER

1

1

921C

STAINLESS STEEL PLATE + HAND PROTECT

2

1

993

STAINLESS STEEL NUT

3

1

412

COMPENSATION RING

4

1

391

PLATE 114

5

1

D114/5MM

KNIFE 114

6

1

CTX_D114

PLATE / KNIFE 114

7

1

D114/00

KNIFE HOLDER 114

8

1

389

STAINLESS STEEL FEED SCREW114

9

1

992

CLAVETTE PLAQUE DE COUPE

10

1

777

VIS TFB FIXATION CLAVETTE

11

1

ECROU BORGNE FORME HAUTE

12

2

ZVIS921

STAINLESS STEEL BODY

13

1

991

BODY RING

14

2

957 BIS

CHOPPER

15

1

993

VIS CHC FIXATION COUVERCLE RÉDUCTEUR

16

8

LIP SEAL TYPE AS

17

1

997A

GEAR BOX COVER

18

1

971

ANNEAU ÉLASTIQUE POUR ALÉSAGE

19

1

998

NEEDLES BEARING

20

1

996E

BORRELLY WASHER

21

1

ZVIS173

BEARING STOP WASHER LS

22

1

996D

NEEDLES CAGE AXIAL AXK

23

1

996C

BEARING STOP WASHER AS

24

1

996B

ROUE AVEC ARBRE + PIGNON INTERMEDIAIRE

25

1

967BIS

PLAQUE INSONORISANTE ( 1 PLAQUE DE 500 x 505 Pour 3

machines )

26

1

799

RONDELLE DE BUTÉE DE ROULEMENT AS

27

1

944

NEEDLES CAGE AXIAL AXK

28

1

946

BEARING STOP WASHER LS

29

1

945

DOUILLE A AIGUILLES HK

30

1

996A

ROULEMENTS A UNE RANGEE DE BILLES A CONTACT RADIAL

31

2

996F

PIGNON INTERMEDIAIRE

32

1

967BIS

GOUPILLE CENTRAGE REDUCTEUR

33

1

044

GEAR BOX BODY

34

1

970

JOINT D'ETANCHEITE POUR BOUCHON

35

1

BOUCHON DE REMPLISSAGE HUILE

36

1

910

LIP SEAL TYPE AS

37

1

997B

THREE PHASES MOTOR

38

1

967

GROWER WASHER

39

4

ZVIS920

VIS A TETE HEXAGONALE ENTIEREMENT FILETEE

40

4

ZVIS918

RONDELLE PLATE

41

6

ZVISI10-004

RONDELLE EVENTAIL EXTERIEUR

42

4

ZVIS083

20

VIS THEF FIXATION REDUCTEUR

43

2

ZVIS007

HEXAGONAL NUT

44

2

ZVIS025

GEAR FIXATION SCREW

45

2

ZVIS919

ION/OFF BUTTON + AUXILIARY BLOCK

46

1

459-2/459-1

ON/OFF BUTTON + CAP + AUXILIARY BLOCK

47

1

936/936A/937B

BOUTON IMPULSION ARRIERE + CAP + AUXILIARY BLOCK

48

1

937D/935B/93C

INSERT TETE CYLINDRIQUE

49

4

VIT020

RONDELLE PLATE

50

4

ZVIS047

RONDELLE EVENTAIL EXTERIEUR

51

4

ZVIS060

VIS A TETE HEXAGONALE ENTIEREMENT FILETEE THEF

52

4

ZVIS092

INSERT TETE CYLINDRIQUE

53

10

Z/105

TOLE SUPPORT BOITIER

54

1

993

INSERT TETE CYLINDRIQUE

55

2

Z/105

RONDELLE PLATE

56

2

ZVIS112

RONDELLE EVENTAIL EXTERIEUR

57

2

ZVIS029

VIS CHC FIXATION TOLE SUPPORT BOITIER

58

2

ZVIS058

ELECTRONIC BOARD

59

1

934

RONDELLE PLATE

60

4

ZVIS035

RONDELLE EVENTAIL EXTERIEUR

61

4

ZVISI10-006

VIS TRL FIXATION BOITIER

62

4

ZVIS074

TÔLE ARRIÈRE INOX

63

1

993

VIS TRL FIXATION TÔLE ARRIÈRE INOX

64

10

ZVIS099

PRESSE ETOUPE + ECROU NOIR

65

1

923

CÂBLE PREMOULE

66

1

ZCAB003

FIXED WHEEL

67

2

9009

ROULETTE PIVOTANTE

68

2

9009BIS

VIS A TETE CYLINDRIQUE A SIX PANS CREUX

69

4

GROWER WASHER

70

4

PROXIMITY CONTACT

71

1

404

CONTACT SUPPORT

72

1

VIS A TETE HEXAGONALE ENTIEREMENT FILETEE THEF

73

2

RONDELLE EVENTAIL EXTERIEUR

74

2

RONDELLE PLATE

75

2

GOUJON FIXATION CORPS

76

2

995

BAGUE DE GUIDAGE CAPOT

77

2

9013

SAFETY GUARD

78

1

993

VIS A TETE HEXAGONALE ENTIEREMENT FILETEE THEF

79

1

BUTEE PLASTIQUE DE CAPOT

80

1

9012

PLASTIC LEG

81

1

VIS TRL

82

1

ANNEAU A MONTAGE RADIAL Ø16x1,5

83

4

9018

ECROU INDESSERRABLE

84

4

AIMANT DE CONTACT

85

1

655

BUTEE TOLE

86

1

993

GREY PLASTIC STOP

87

4

9011

VIS A TETE HEXAGONALE ENTIEREMENT FILETEE THEF

88

2

VIS TF FIXATION AIMANT

89

4

CLE DE SERRAGE ECROU BORGNE ( S=24)

90

1

993

Table of contents

Other PSV groupe Kitchen Appliance manuals