PSV groupe DRC-C10 User manual

1

R

RE

EF

FR

RI

IG

GE

ER

RA

AT

TE

ED

D

M

MI

IN

NC

CE

ER

R

D

DR

RC

C

-

-

C

C1

10

0

U

Us

se

er

r

G

Gu

ui

id

de

e

Usine du berre au Loup –RD147 –BP20 –95420 Genainville –France

Brand, patents and models registered in France and abroad R.C.S. Pontoise B 642

033443

2

NEW EQUIPMENT COVERED BY THE DIRECTIVE

1. CEM 2014 / 30 / UE

2. BT 2014 / 35 / UE

3. MACHINE 2006 / 42 / CE

CERTIFICATE OF COMPLIANCE rules of the European

Community.

The Manufacturer hereby PSV Groupe, BP20 95420 Genainville

certifies that the new material designated below:

REFRIGERATED MINCER

TYPE : ………….

Serial number : ………….

Genainville, done on ………….

M. Michel PATUREL

CEO

3

TABLE OF CONTENTS

1 / INTRODUCTION AND STANDARDS --------------------------------------------p.4

2 / INSTALLATION AND ELECTRICAL CONNECTION-------------------------p.5

3 / FEATURES AND SPECIFICATIONS---------------------------------------------p.6

4 / DESCRIPTION -------------------------------------------------------------------------p.8

A / INSTALLING THE BODY------------------------------------------------------------------------------ p.8

B / MOUNTING PLATES AND KNIVES --------------------------------------------------------------- p.9

5 / MAINTENANCE. -------------------------------------------------------------------- p.12

A / CLEANING THE MACHINE -------------------------------------------------------------------------p.12

B / PRELIMINARY CLEANING--------------------------------------------------------------------------p.12

C / DISINFECTION-----------------------------------------------------------------------------------------p.12

D / RINSE ----------------------------------------------------------------------------------------------------p.13

E / MAINTENANCE: ---------------------------------------------------------------------------------------p.13

6 / WARNING ----------------------------------------------------------------------------- p.14

7 / ACCESSORIES---------------------------------------------------------------------- p.14

8 / CUSTOMER SERVICE------------------------------------------------------------- p.14

9 / WARRANTY--------------------------------------------------------------------------- p.16

10/ INSTALLING THE STEAK RECONSTITUOR ---------------------------p.17-18

11/ USING THE STEAK RECONSTITUOR ---------------------------------- p.19/20

12/ EXPLODED VIEW of STEAK RECONSTITUOR ----------------------- p.22/23

13/ EXPLODED VIEW of MINCER -------------------------------------------------- p.24

14/ NOMENCLATURE OF MINCER -------------------------------------------- p.25/26

15/ EXPLODED VIEW GEAR BOX-------------------------------------------------- p.27

16/ EXPLODED VIEW BODY--------------------------------------------------------- p.28

17/ EXPLODED VIEW CONTROL PARTS---------------------------------------- p.29

18/ CONTROLS ------------------------------------------------------------------p.30/31/32

19/ ELECTRIC SCHEME -------------------------------------------------------------- p.33

20/ ISTALATION AND SETTINGS OF TERMOSTAMETRE-------------- p.34/35

4

1/ INTRODUCTION

DRC H12 mincer can mincer all kinds of meat for the production of

hamburgers, meatballs, sausage, etc.. ...

It has Three cutting elements version UNGER 82 (2 plates and double

cutting knife).

STANDARDS

These devices meet the requirements of the decrees and safety

standards.

General hygiene and safety laid down in Articles 84 to R233-R233-

106, introduced in the Labour Decree No. 80543 of July 15, 1980.

French standard NF U66-062, Machine chopping meat, integrated

prevention.

The control devices and signage, exhibit a degree of protection IP54

as defined in standard NF 20-010.

All devices present a degree of protection IP245.

Continuous sound pressure level equivalent to the Workstation measured

according to standard NF S31 124 P <70 dB (A) empty and loaded

5

2/ INSTALLATION

Position the machine on a stable and solid work surface.

See recommended height of sketches above.

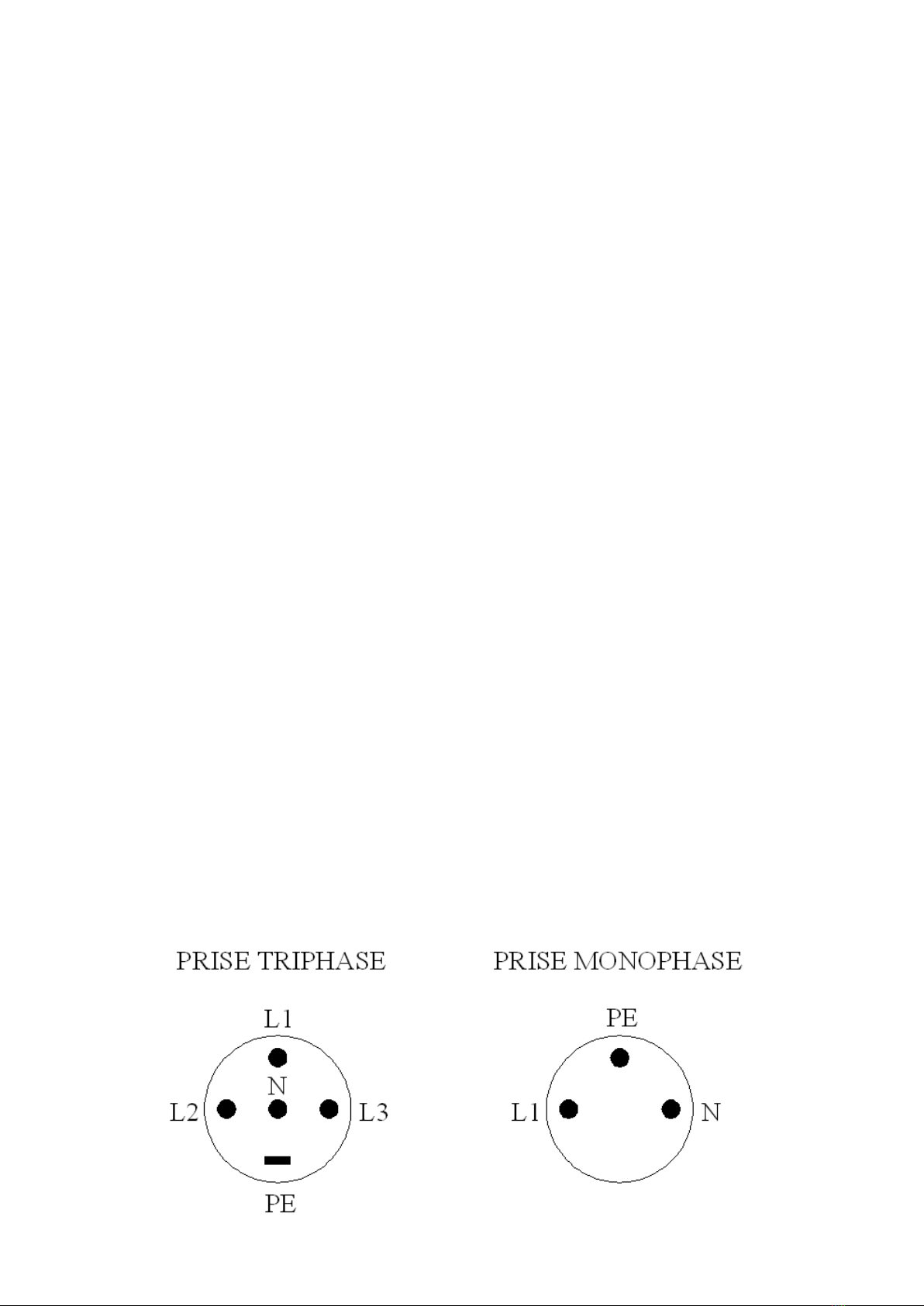

ELECTRICAL CONNECTION

The electrical connection must be performed by qualified personnel and be

conducted in compliance with safety standards in force.

6

The line of the power supply must be carried out using a cable

section adapted to the power of the machine and must include two

phase conductors and a grounding conductor (voltage machine

230v, 50 Hz) .

The power of the machine must be protected by a breaker.

Cooling system power is secured by a specific breaker Réf Ø5x20 / 2,5A.

7

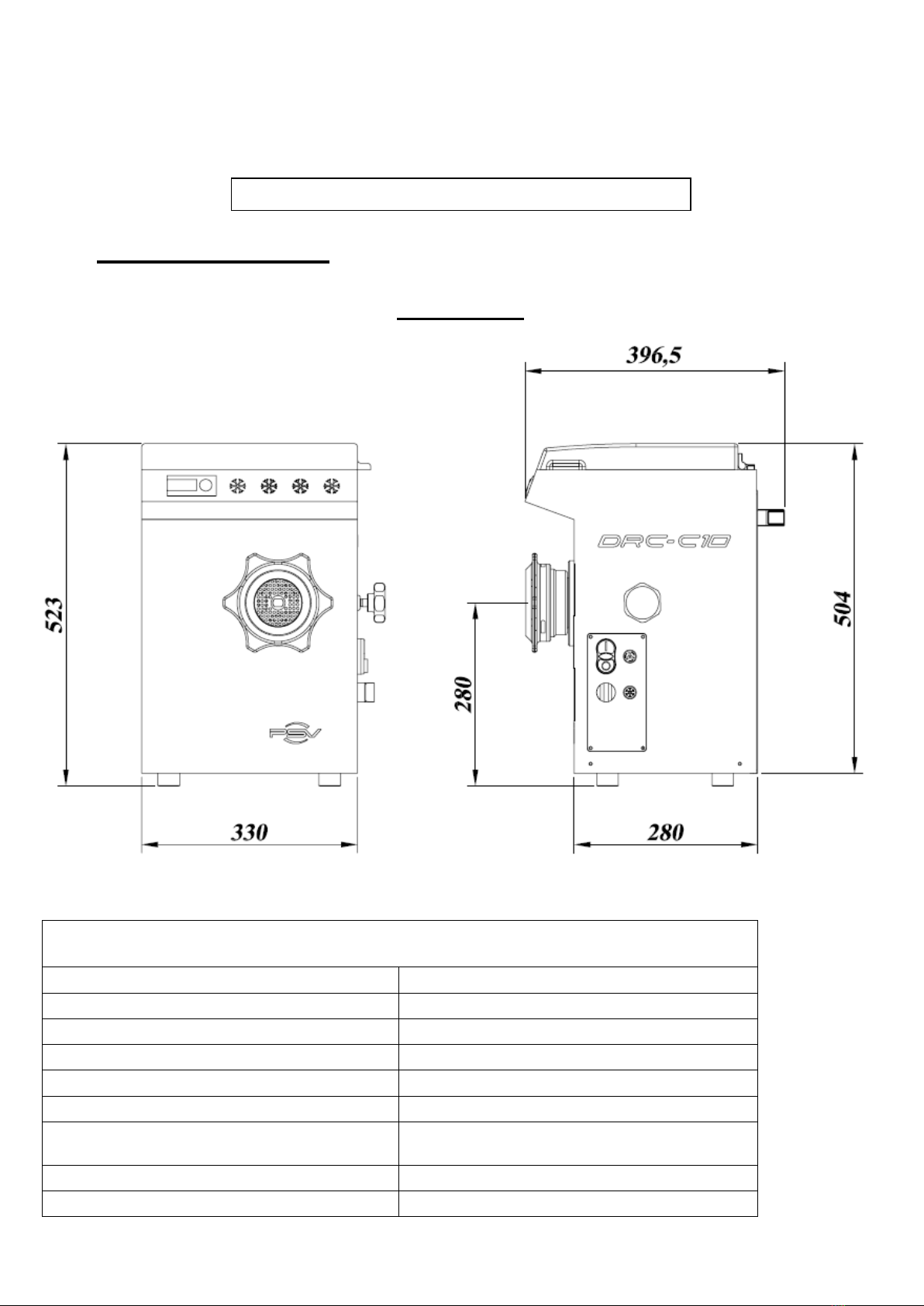

3/ FEATURES

TECHNICAL SHEET

DRC –C10

Specifications

DRC –C10

Dimensions (mm)

396,5 x 330 x 504

Weight

52kg

Packing (mm)

655x460x705

Théoritical flom

300 kg/h

Engine

1,5CV / 1,12 KW continu

Voltage

TRI - 400v - 50 HZ /

MONO - 230V - 50HZ

Gear Box

PSV

Cutting System

Double cut H82 SUPINOX

8

Standard equipment

1 double knife, 1 cutting plate, 1

plateØ3

Gaz

R134A

4/ DESCRIPTION

A / INSTALLING THE BODY

Present the body in front of the machine.

Fit the body in its seat .

Tighten the nut until red ring can not been seen anymore.

9

Be sure body is well tighten

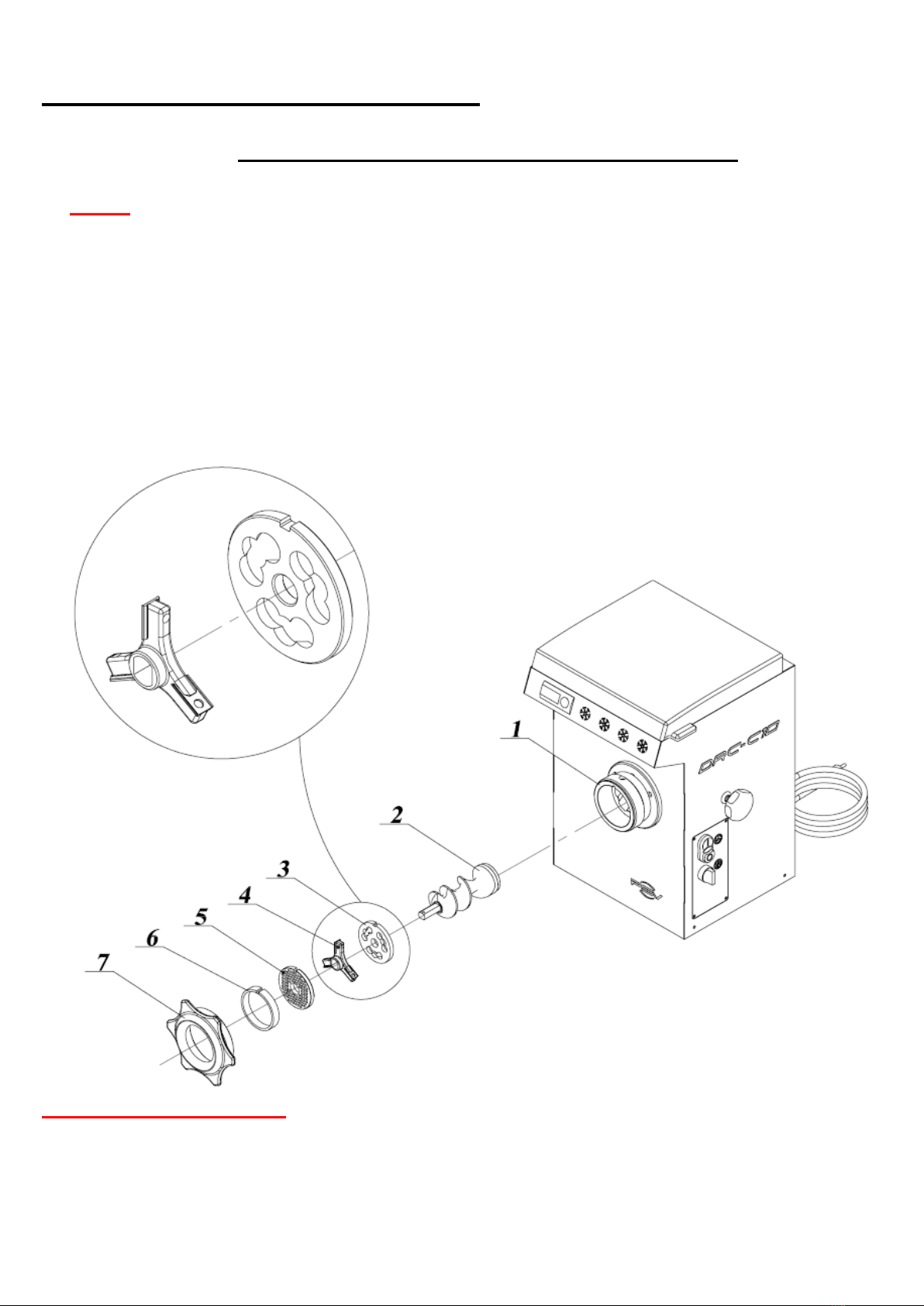

B / MOUNTING PLATES AND KNIVES

1/ SYSTEM WITH 3 CUTTING ELEMENTS (UNGER).

NOTE : Disconnect the machine from the electricity grid for the

following:

Insert the A-helix (2) inside the body (1) with a slight twisting motion for a

good engagement with the hex output shaft engine.

B-Fit the knife plate (3).

C-Mount the blade (4).

D-Mount plate (5).

E-Assemble the ring (6).

F-mount stainless steel nut (7).

VERY IMPORTANT :

It is essential to follow the order of assembly

Do not mount the entire body / propeller and cutting system at

once.

1

0

Installation should be done as described above in several

phases.

2/ PRECAUTIONS FOR INSTALLATION AND MAINTENANCE

SYSTEM UNGER

Make sure that the cutting system is mounted exactly as shown below.

Improper installation, including upside down, causing breakage of the

blades or plates.

The plate must be perfectly knife against the face of the body of the

chopper.

The nut stainless steel machine should not be tightened significantly.

Change the blades before they are flush with the branches of the knife.

To surface plates from wear. Plates prevent waste a perfect fit and cause

rapid wear of the blades.

A- PLATE A-KNIFE

B-DOUBLE FACE KNIFE (shoulder outlet plate side )

C-PLATE WITH HOLES

1

1

C/ STARTING

Initialize coolign system 15 minutes before first mincing of the day

(settings of temperatures).

Cooling system must always be on, even for non-continuous mincing.

NF EN 12331+A2 2010-07 information reagrding temperature having

to be below 7°C inside the whole way for meat from tray to cuting

system. Meat should not be stored on the tray.

Digital temperature screen has to meanings : showing temperature and

regulating (thermostat) the cooling system.

Temperature of régulation is settled between 3°c and 4°c.

While working, regulations must not vary widely.

Do not minced frozen meat, juice, bones...

5/ MAINTENANCE

DISCONNECT BEFORE ANY WORK ON THE UNIT

A/ CLEANING THE MACHINE :

For obvious reasons of hygiene, meat mincing machines require extensive

and frequent cleanings. They must be kept perfectly clean and

1

2

maintenance, disassembled, cleaned and disinfected after each half day of

work.

To do so, we recommend to use detergent (like dish soap or ammonia

products).

B/ Preliminary cleaning:

Remove visible dirt by brushing (body, propeller, screw, plates and knives).

C/ DISINFECTION

Immerse all removable parts in a bath of warm water (Temperature 45-55 °

C.) with a detergent-disinfectant appropriate.

For the plate and body wash in warm water with the same detergent-

disinfectant.

D/ FLUSH

Rinse the removable parts, rinse the plate, and the body.

Do not immerse the device. Do not clean the jet pressure

The brushes used must be cleaned in a detergent solution and rinsed.

The body of the chopper does not require special maintenance. Just use a

towel or disposable paper moistened.

Avoid using abrasive cleaners that will damage the steel. Sponges are

prohibited.

E/ MAINTENANCE

The gearbox requires no maintenance.

6/ WARNING

PROTECTION AGAINST THE RISK OF CUTS CAUSED BY KNIVES:

There is a serious risk when the operator can move the fingers through the

1

3

plate of hash, as the knife rotates in contact with it.

When the holes have a diameter less than 4mm, the risk of introduction of

the fingers does not exist (CF NF E 09-010). It is the same for diameters

between 4 and 8mm included, provided that the plate has a thickness of

5mm.

For hole diameters greater than 8mm or specially shaped openings (in

beans for example), it is necessary to develop a device that prevents

access to the dangerous part.

7/ ACCESSORIES

Your device comes with a pestle in food.

8/ AFTER SALES SERVICE

After-sales service is performed by your dealer:

He will ensure the start and the possible restoration of your device and he

will provide spare parts and accessories.

9/ WARRANTY

As a manufacturer, we guarantee our equipment one year against any

manufacturing defect, the bill acting as a warranty.

IMPORTANT:

The electrical and electronic parts are excluded from the warranty.

LIMIT OF OUR GUARANTEE:

The warranty applies only to the purchaser and not to third parties to which

the material could be resold.

Our guarantee is limited to replacement or repair free of parts found

defective by us. In this case, the material is returned to us prepaid.

The port and the workforce are in all cases be borne by our distributor.

All comments and not misuse by special instructions, changes,

modifications, or repairs outside the workshop of an authorized dealer, and

the lack of identification plate, result in the cancellation of the guarantee.

1

4

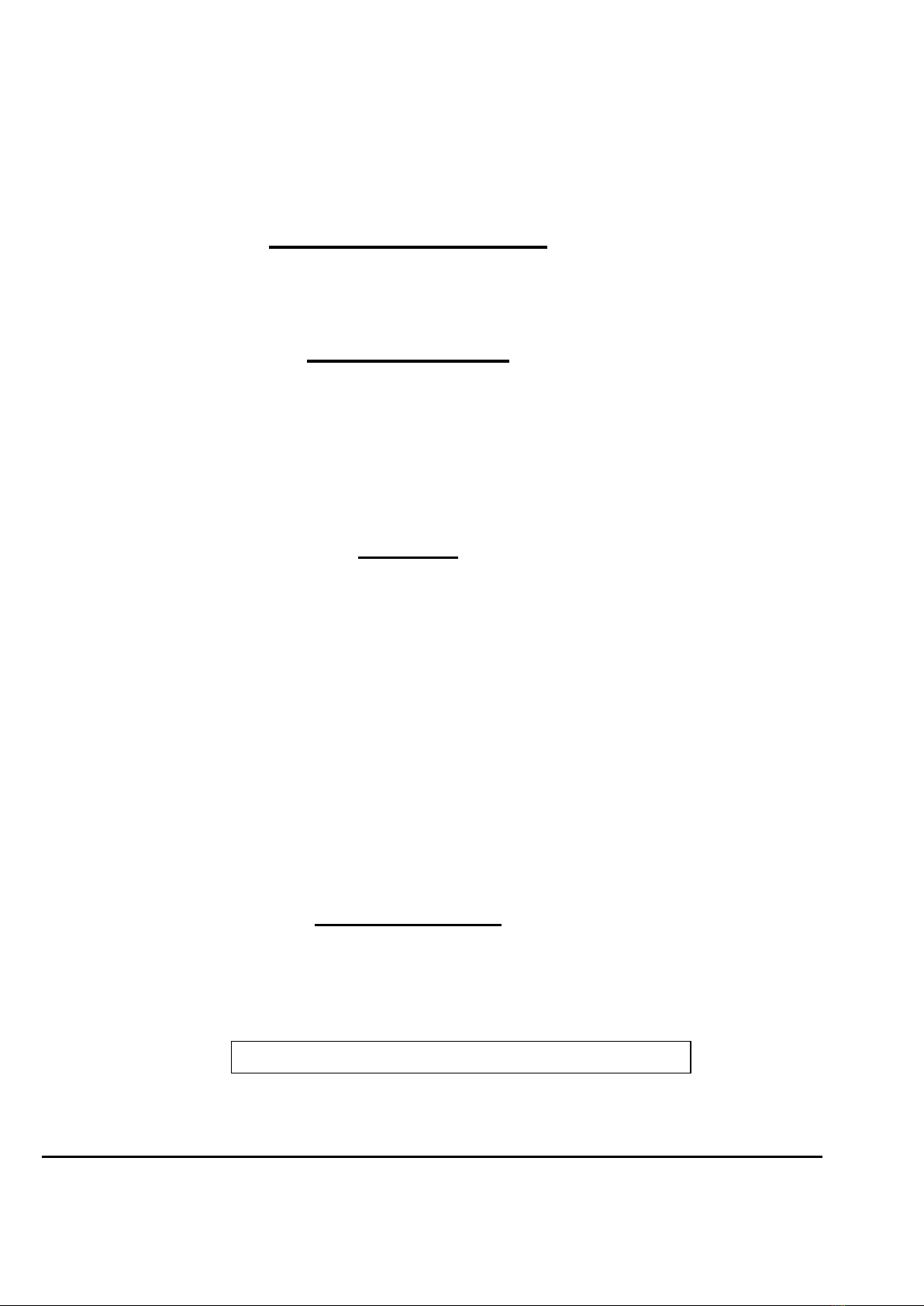

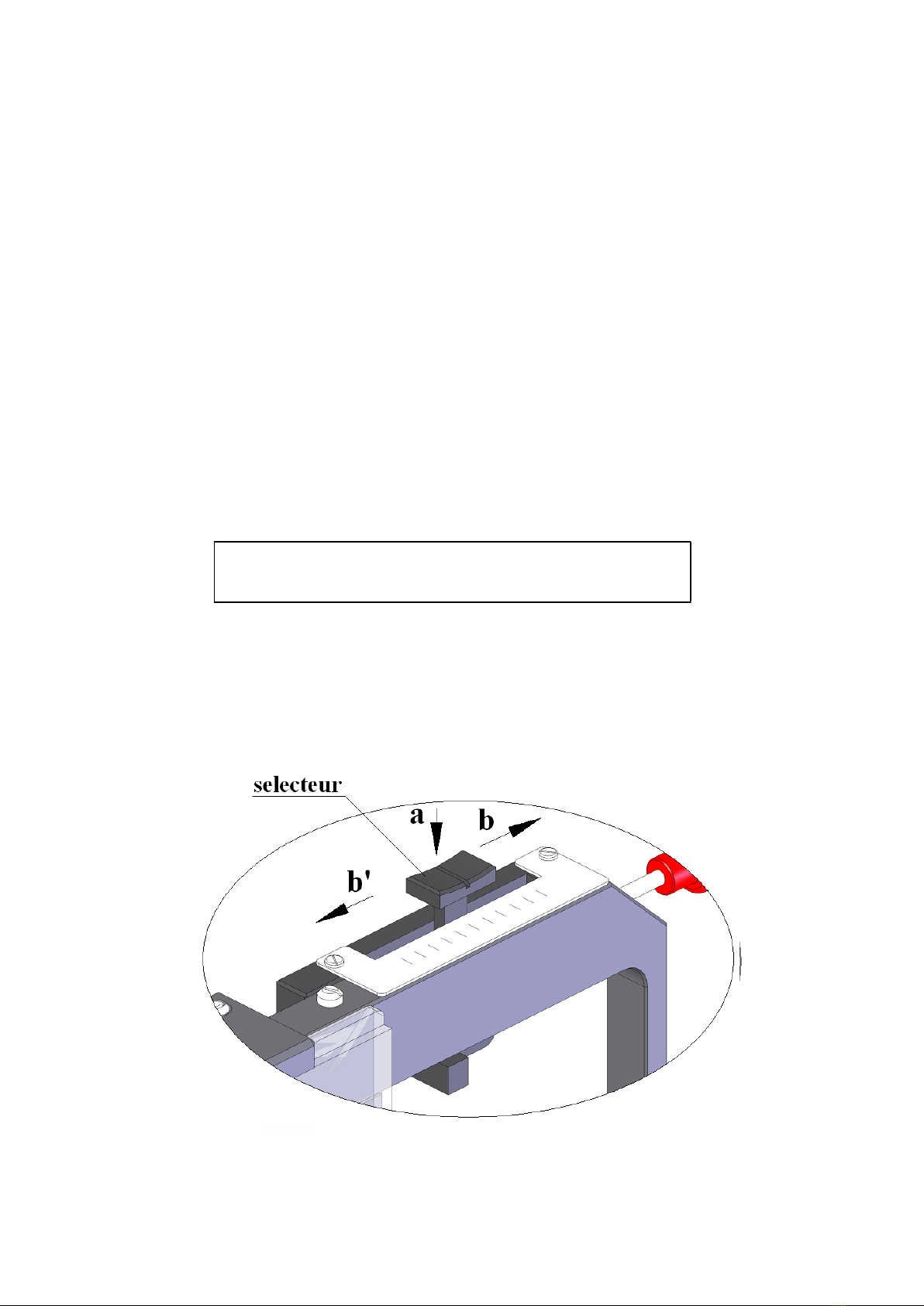

10/ INSTALLATION OF STEAK

RECONSTITUOR (OPTIONAL)

Place support Aon mincer nut and lock it with fork 7and with button 8.

Place the body of B.

Slide the Cplate inside the ray of the support.

1

5

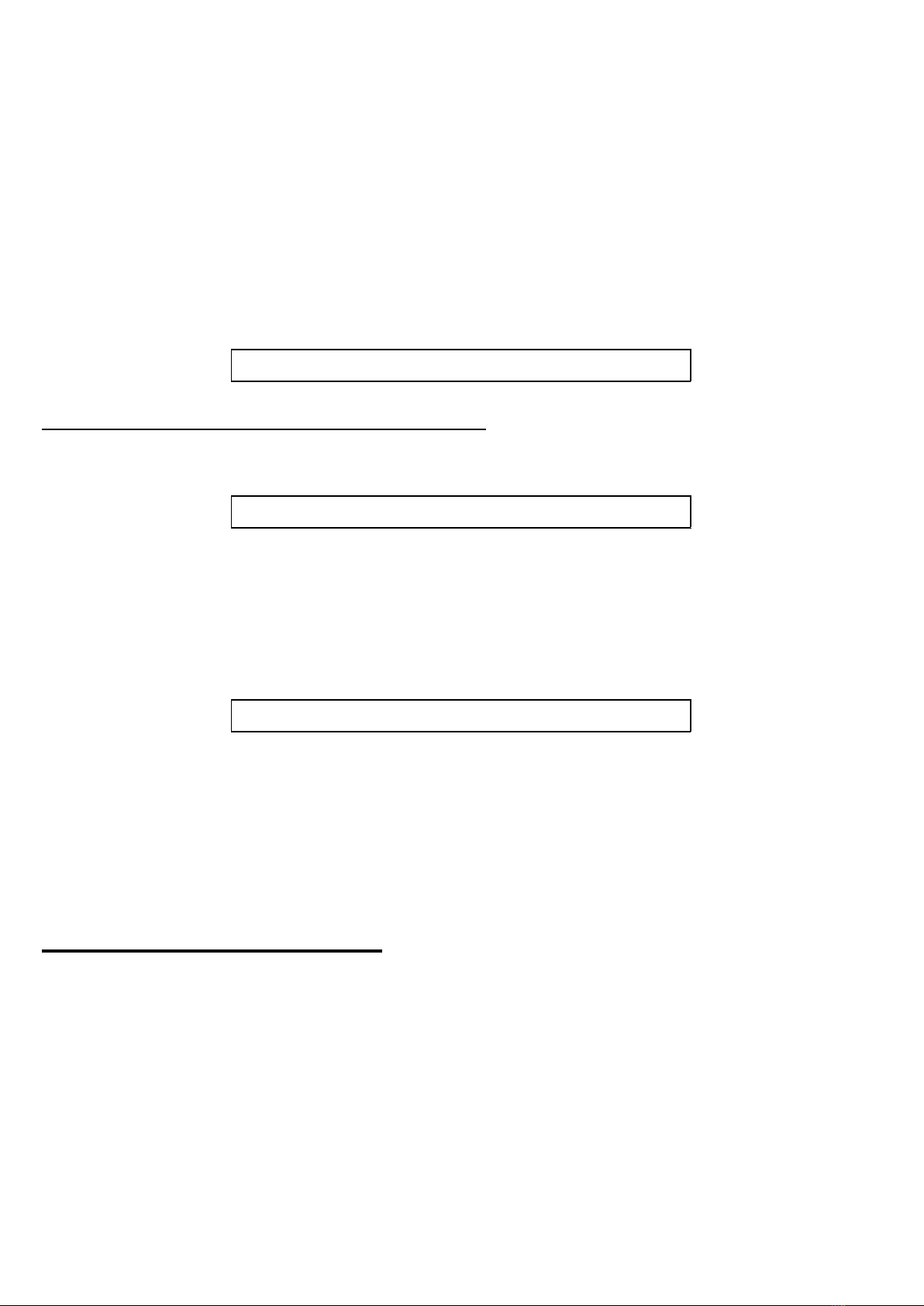

11/ USING OF STEAK

RECONSTITUOR

1/ Sélect reconstituor mode on control board, pages (31/32).

2/ push sélector to set weight.

3/ push against the body.

1

6

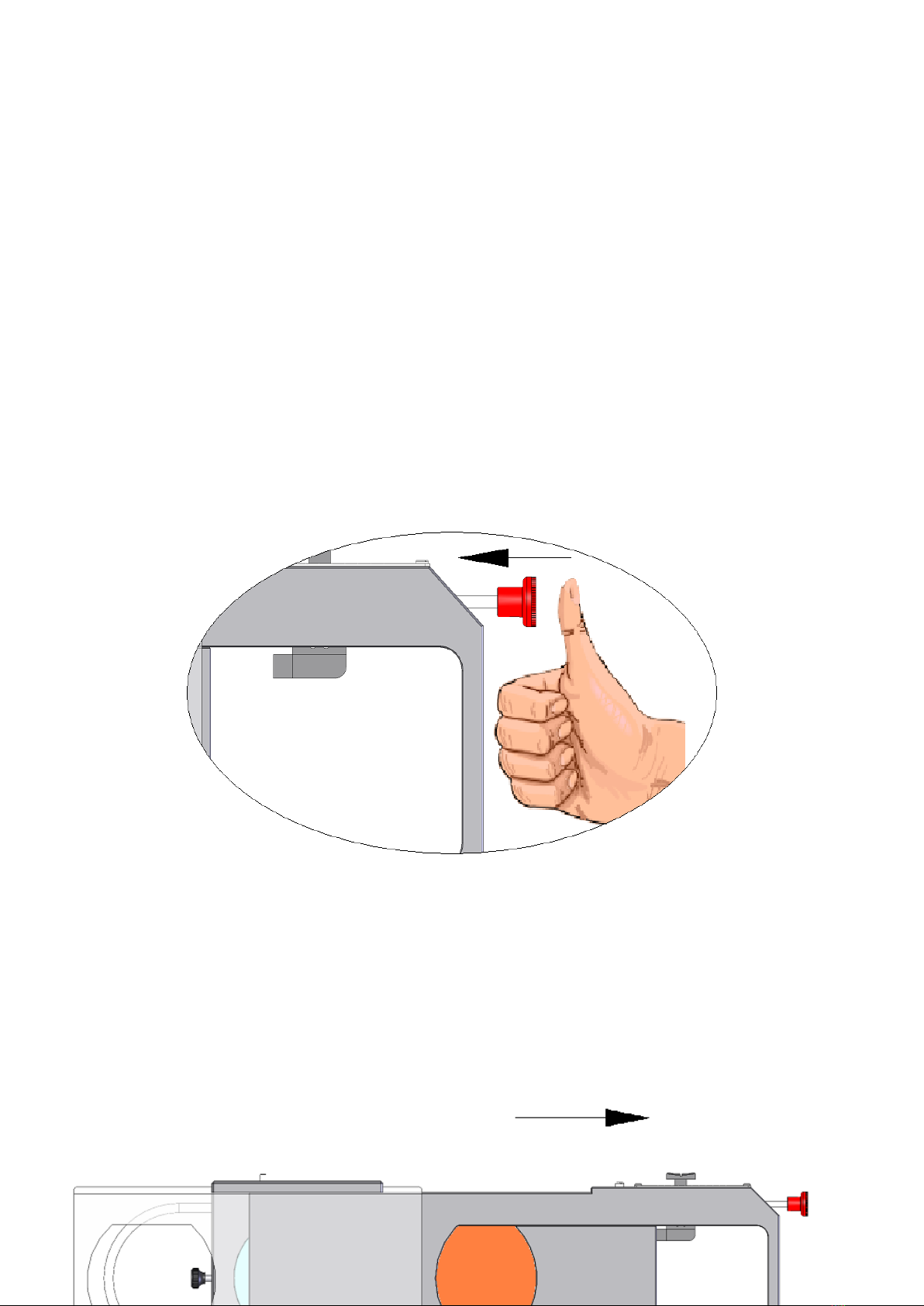

4/ Press button to start mincing and form steack

5/ mincing stops automatically and burger can be realised by pulling the

device to the right.

1

7

Using reconstituor in bulk mode :

Pull the plexi plate to the right.

Place the mouth in front of the plate of mincer so the met can go out

continously

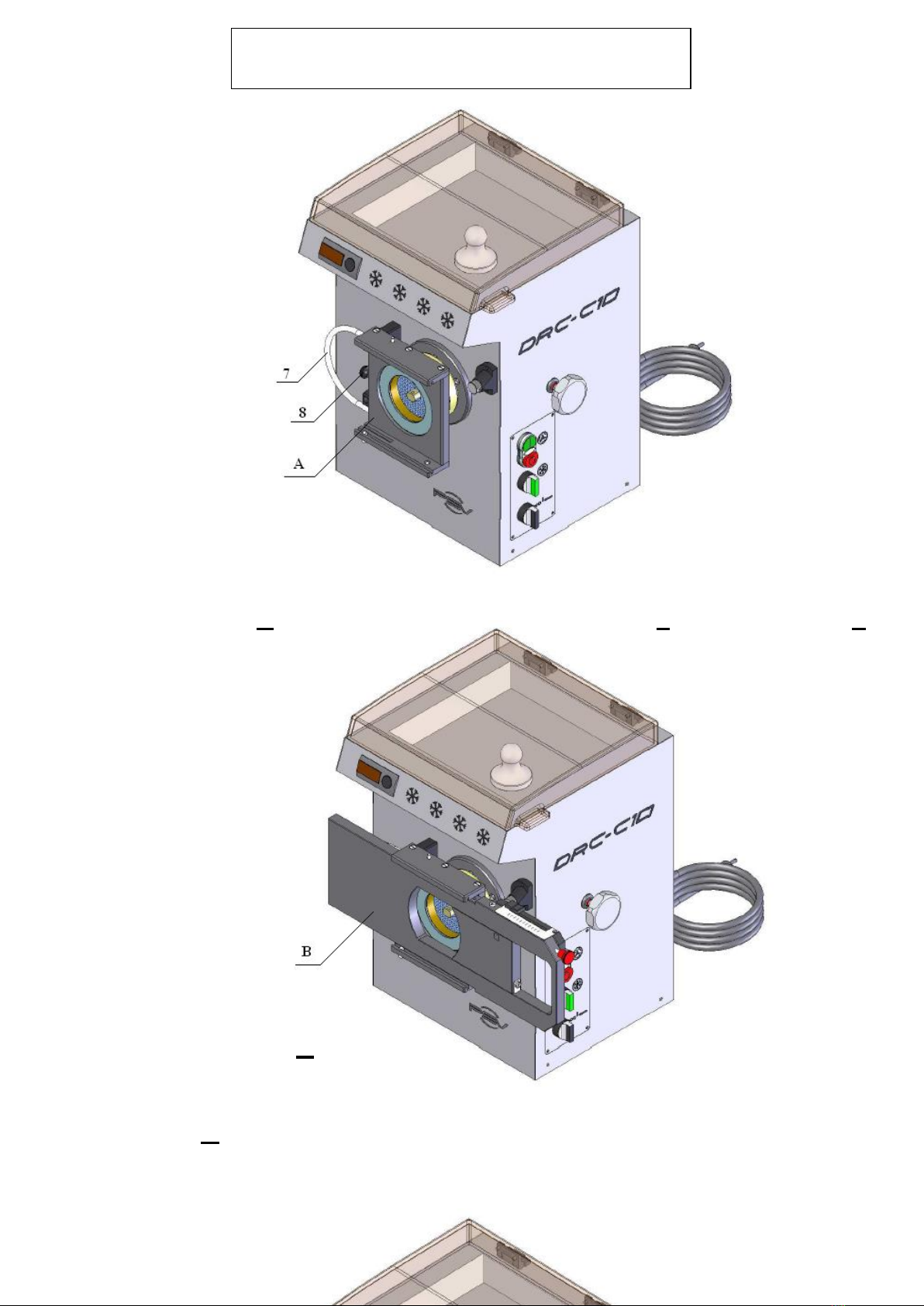

EXPLODED AND NOMENCLATURE

HACHOIR –DRC-C10

1

8

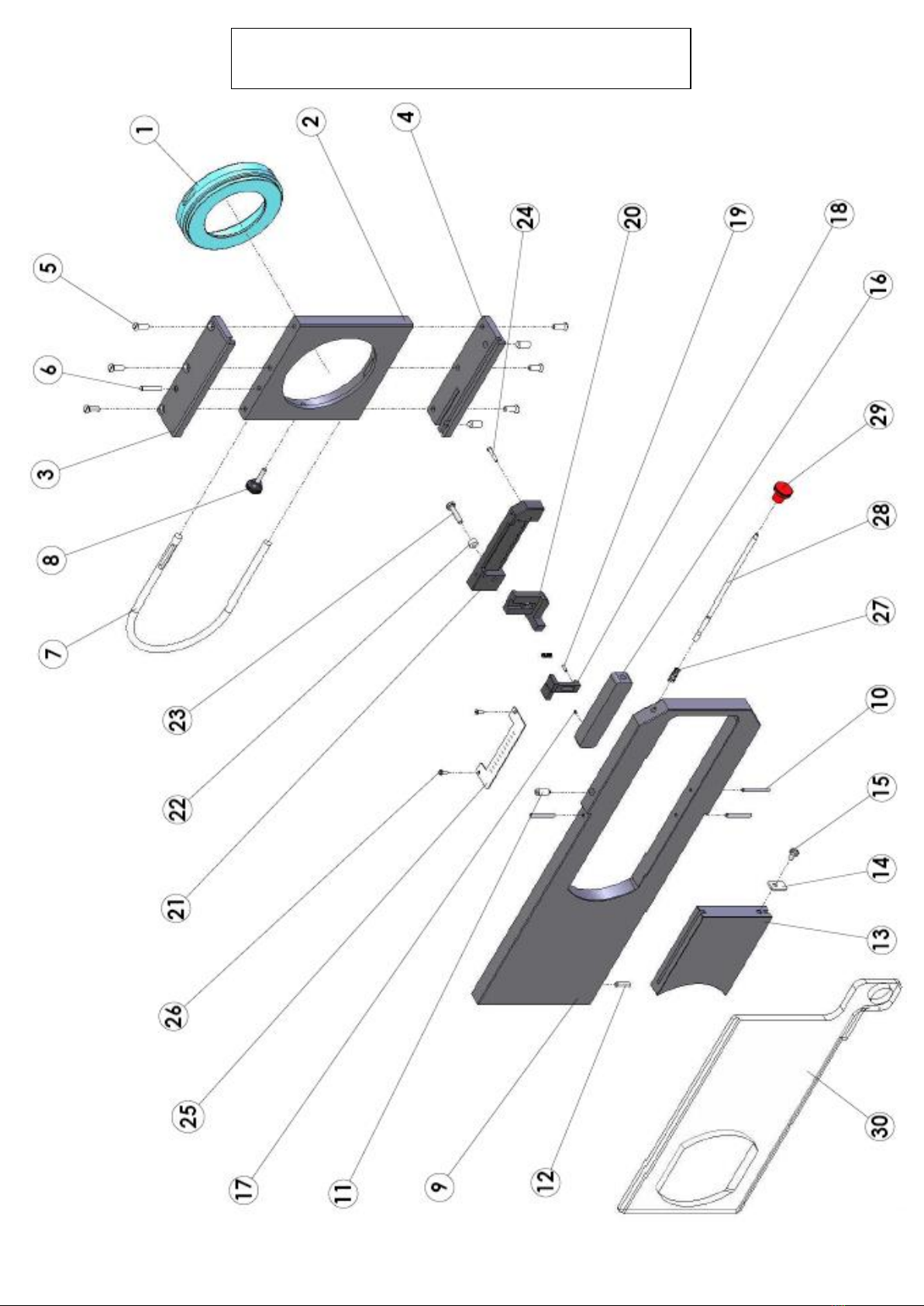

12/ EXPLODED VIEW OF

RECONSTITUOR

1

9

Burger forming device spare parts

SCHEME

NB

DESCRIPTIONS

QUANTITY

PART

NUMBER

NET PRICE

€

1

BODY SCREW

1

104

124

2

SUPPORT TIROIR

1

1018

80

3

PIECE 1 SUPPORT

TIROIR

1

1019

30

4

PIECE 2 SUPPORT

TIROIR

1

1020

30

5

VIS TF

6

ZVIS062

6

AXE DE POIGNEE

1

186

7

FOURCHETTE

1

132

11

8

BOUTON DE

SERRAGE

1

133

2

9

CHASSIS TIROIR

1

1021

86

10

AXE GUIDAGE DEMI

EMPREINTE

1 // 2

200 //192

11

BUTEE A BILLE

2

189

6

12

AXE BUTEE TIROIR

1

178

12

13

DEMI EMPREINTE

TIROIR

1

1022

39

14

BUTEE DE DEMI

EMPREINTE

1

110

1

15

VIS TCL

1

ZVIS145

1

16

GLISSIERE DE

SUPPORT

SELECTEUR

1

1023

24

17

VIS SANS TETE SIX

PANS

1

ZVIS123

1

18

SELECTEUR

1

1024

27

19

GOUPILLE

1

203

3

20

GUIDE SELECTEUR

1

1025

32

21

SUPPORT

SELECTEUR

1

1026

44

22

ENTRETOISE RONDE

1

031

1

23

VIS TCL

1

ZVIS144

1

24

VIS TF

1

ZVIS066

1.1

25

SUPPORT ETIQUETTE

GRAMMAGE

1

131

6

26

VIS TCL

2

ZVIS146

1

27

RESSORTS

2

204 // 205

4 // 2

28

AXE DE RELANCE

CYCLE

1

194

9

29

BOUTON BORNE DE

RELANCE CYCLE

1

188

3

30

FENETRE

1

1027

51

31

ETIQUETTE

GRAMMAGE

1

179

2

2

0

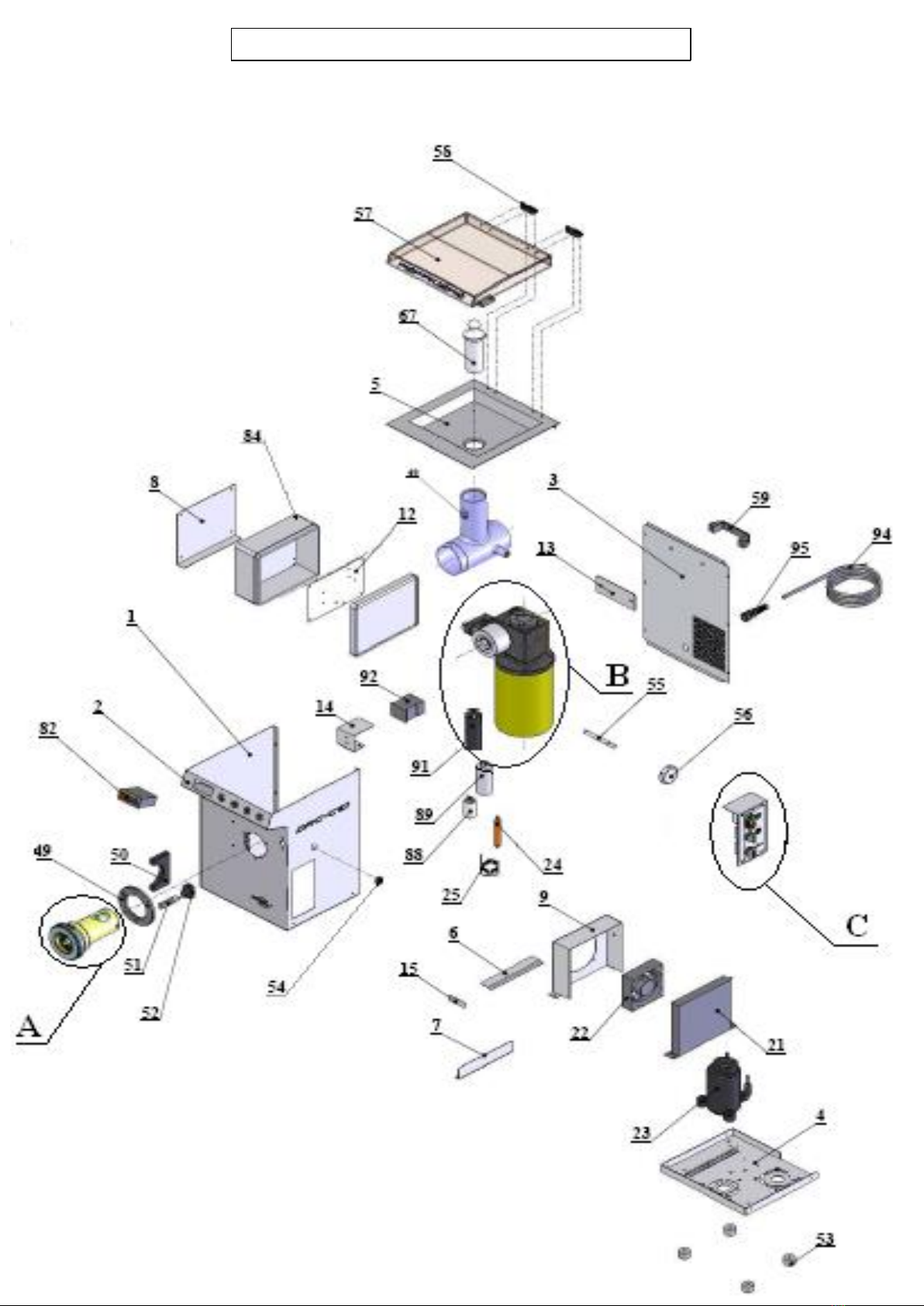

13/ EXPLODED MINCER DRC-C10

Table of contents

Other PSV groupe Kitchen Appliance manuals