PTI TorqTraQ User manual

Operator’s Manual

Revision 2.3

1440 Timberwolf Drive | Holland, OH 43528

419.867.5400 | www.pti-usa.com

Table of Contents

- 2 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

1CONTENTS (CLICK ON TEXT BELOW TO JUMP TO SECTION)

2Getting Started................................................................................................................................ - 3 -

2.1 Step 1: Charging the battery .................................................................................................... - 3 -

2.2 Step 2: Installing the software and drivers .............................................................................. - 3 -

2.3 Step 3: Setting the device clock to local time .......................................................................... - 5 -

2.4 Step 4: Installing a closure-specific chuck................................................................................ - 7 -

3TorqTraQ®device general operation .............................................................................................. - 8 -

3.1 Operating the device................................................................................................................ - 8 -

3.2 Removing a closure .................................................................................................................. - 8 -

3.3Applying a closure .................................................................................................................... - 8 -

3.4 Storing readings to memory..................................................................................................... - 8 -

3.5 Measuring band break ............................................................................................................. - 8 -

3.6 TorqTraQ®device menu ........................................................................................................... - 9 -

4Using the desktop software.......................................................................................................... - 11 -

4.1 Main Screen............................................................................................................................ - 11 -

4.2 Configure ................................................................................................................................ - 12 -

4.3 View Data ............................................................................................................................... - 13 -

4.3.1 Report screen (export to Excel) ...................................................................................... - 14 -

4.4 Validate .................................................................................................................................. - 15 -

5Storage .......................................................................................................................................... - 16 -

6Cleaning the device....................................................................................................................... - 16 -

7Safety notes .................................................................................................................................. - 16 -

8Service, Warranty, and Calibration............................................................................................... - 17 -

9Specifications ................................................................................................................................ - 18 -

10 Contact Information...................................................................................................................... - 19 -

11 Appendix – Legacy method of operation...................................................................................... - 20 -

Table of Contents

- 3 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

2GETTING STARTED

2.1 Step 1: Charging the battery

1. Connect the device to a powered USB port on a computer or USB wall charger (not included) using

the provided cable.

2. The display on the TorqTraQ®device will show battery strength by the number of bars that appear.

While the battery is charging, “Chrg” will appear on the display. Once the battery is fully charged,

“Batt” will be displayed.

3. Once the battery is fully charged, the display will change from Chrg to Batt and show full bars. As

the battery “tops off” towards the end of the charging cycle, the display might switch between

Chrg and Batt.

4. The battery scale (number of bars) calibrates during the first full charge. The battery scale may be

inaccurate until this occurs.

Note: If the battery level is very low when charging begins, the display will initially remain blank,

and the Application and Removal lights will flash every five seconds. Once the battery has charged

to a sufficient level to power the display, the display will begin to show the charging status.

Additional information: The TorqTraQ® device has an internal Lithium-Ion rechargeable battery. These

are long life batteries that can withstand many charging cycles; if the battery life seems short, contact

the TorqTraQ® manufacturer. When first unpacking the device, it must be fully charged using the

provided USB cable. A full battery charge takes approximately 3-4 hours depending on the battery level

when charging began. A full charge should last 8-12 hours depending on level of continuous usage. In

standby mode the battery will last many days. If the battery fully depletes, the internal clock will lose

time. If this happens, see Section 2.3 to set the clock on the device.

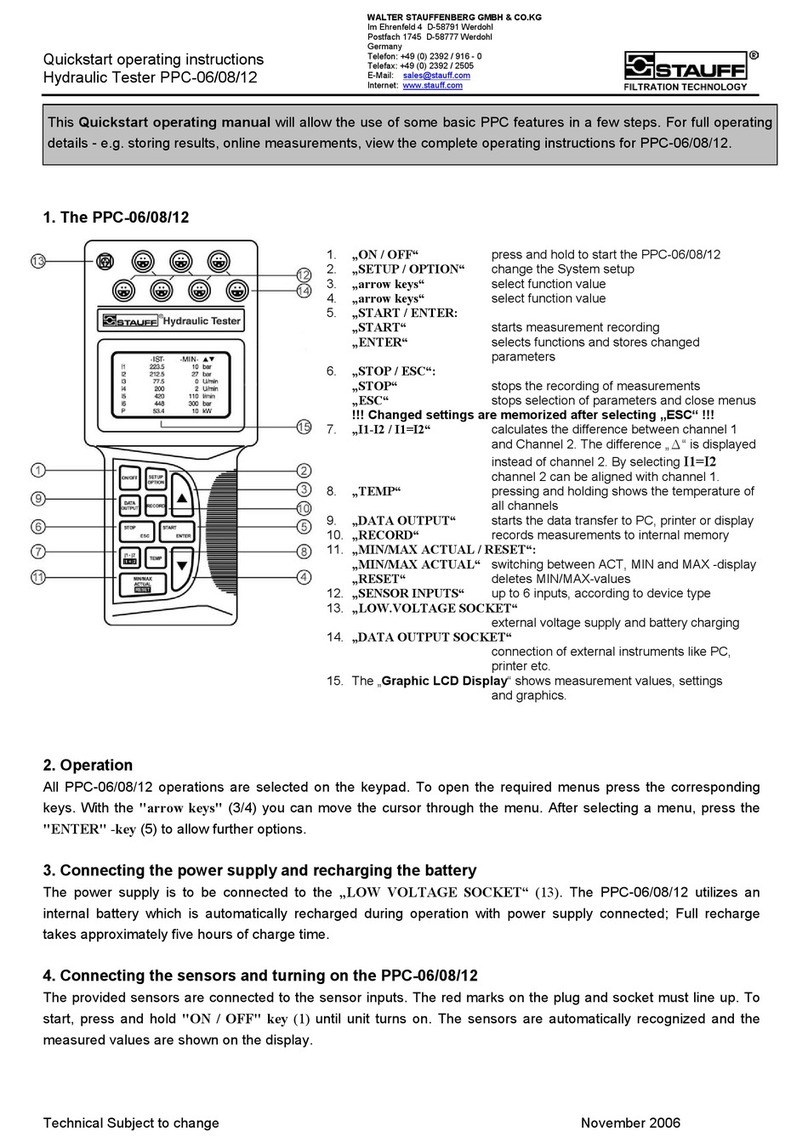

2.2 Step 2: Installing the software and drivers

This step should be performed by a system administrator. The software and drivers are compatible

with Windows XP through Windows 7.

1. Insert the provided CD rom into the computer

2. The CD should automatically run the installation program. If the CD does not automatically load

the installation program, browse the files on the CD and run setup.exe in the root directory.

3. Once the installer begins, follow the prompts on the screen (shown below). During this process

Windows might display security screens confirming the installation; accept these screens as

they appear (not shown below).

Table of Contents

- 4 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

1

2

3

4

5

6

Table of Contents

- 5 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

Installation is now complete.

4. The software can be found under:

Program Files/Plastic Technologies, Inc/TorqTraQ Desktop Software

Full software instructions can be found in Section 4 of this manual.

2.3 Step 3: Setting the device clock to local time

The device includes a timestamp on every reading stored, so it is important to make sure the local time

is maintained on the device. From the factory, the device clock is set to U.S. Eastern Standard Time

(EST).

The following steps assume the software and device driver have been successfully installed on a

computer. Setting the device clock:

1. Plug the TorqTraQ® device into the computer using the provided USB cable

2. Load the software through the Windows Start menu, by default the software will be located:

Program Files/Plastic Technologies, Inc/TorqTraQ Desktop Software

3. The software will load into the main screen:

7

8

Table of Contents

- 6 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

4. The device should appear in the upper Attached Devices window. If the device does not appear

in this window, unplug the device, plug the device back in, and hit the refresh button.

5. To set the clock on the device, click the configure button. The following window will appear:

6. Click the Save to Device button. This synchronizes the device clock to the time setting on the

computer as demonstrated above.

Full software instructions can be found in Section 4 of this manual.

Table of Contents

- 7 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

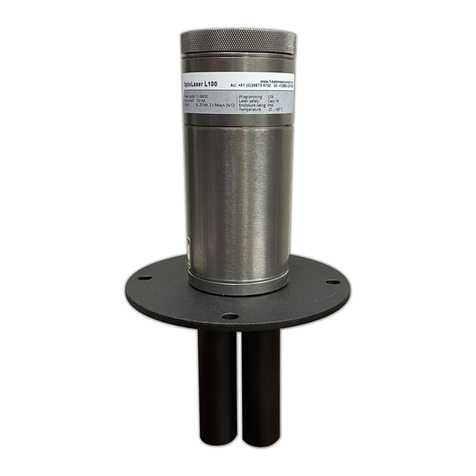

2.4 Step 4: Installing a closure-specific chuck

The chuck is the gripping mechanism that ensures that the TorqTraQ®device will properly mate with

closures. Each TorqTraQ®device will be shipped with at least one chuck. To install a closure-specific

chuck, please follow the following procedure. Failure to do so may damage the unit and void any

warranties.

Two-screw chucks:

1. Place the chuck into chuck pocket on bottom

of device.

2. Rotate the chuck until the two mounting holes

line up with the threaded holes.

3.

Use two screws to mount the chuck, the

screws should be snug – do not over-tighten.

Hardware used (provided):

Two #6-32 SS flathead screws, 1/4

” overall

length

One-screw chucks:

1. Place the chuck into chuck pocket on bottom

of device.

2. Rotate the chuck until the chuck drops into

place, the lugs on the bottom of the chuck will

drop into matching pockets on the device.

3. Use the one screw to mount the chuck, the

screw should be snug – do not over-tighten.

Hardware used (provided):

One #8-32 SS flathead screw, 5/16” overall

length

CAUTION: The screw lengths mentioned reference the overall length of the screw, do not exceed these

lengths or use different screws. Screws should be snug; do not over-tighten.

TIP: For customers with liquid products (soda, milk, juice, etc):

There is a possibility for product to get on the device and seep behind and around the chuck. When

the product dries it can become sticky and potentially “glue” the chuck into place, making it very

difficult to remove. In some cases the chuck becomes damaged upon removal. If the packaged being

tested contains a liquid product, it is recommended the operator coats the bottom and sides of the

chuck pocket with white lithium grease (or similar grease that can fill voids

) prior to installing a chuck.

Any excess grease should be wiped off once the chuck is installed. The grease will fill the voids and

keep the product from seeping into cracks and drying. Grease is not included with the device.

Table of Contents

- 8 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

3TORQTRAQ®DEVICE GENERAL OPERATION

3.1 Operating the device

The TorqTraQ®device is turned on by pressing the zero button on the device.Upon startup, the display

will scroll information about the device and then read “0.0”. At this point, the device is ready to take

measurements. The device can be operated with or without the USB cable plugged in, assuming the

battery is charged.

3.2 Removing a closure

1. Grip the container firmly in one hand, and the TorqTraQ®device in the

other. The TorqTraQ®chuck should be caref

ully placed over the

closure; making sure the chuck is perpendicular to the closure.

2. Press the zero button after

the chuck has been firmly fitted to the

closure and before rotational force has been applied.

3. Hold the container firmly and turn the device counter-

clockwise to

remove the closure. Rotation should be slow and steady for the most

accurate and repeatable results.

4. The peak torque is now displayed on the screen. See Section 3.4 for

next steps.

If after a test, the display “snaps back” to zero, the test was performed too quickly.

3.3 Applying a closure

1. Follow steps outlined in Section 3.2 above, turning the device in clockwise direction. Live

torque readings will display on the screen during the application; the operator must stop the

test when the torque reaches the desired application torque.

2. The peak torque is now displayed on the screen. See Section 3.4 above for next steps.

3.4 Storing readings to memory

For devices shipped prior to November 2012, please see Section 11 Appendix – Legacy method of

operation.

Start by completing a test using the instructions above; a peak torque reading should be on the display.

With the peak torque still on the display, press and hold the zero button for one second. The reading

will be stored in memory, and the memory location “xxx/250” will be displayed on the device screen.

3.5 Measuring band break

1. Grip the container firmly in one hand, and the TorqTraQ®device in the other. The TorqTraQ®

chuck should be carefully placed over the closure; making sure the chuck is perpendicular to

the closure.

2. Press the zero button after the chuck has been firmly fitted to the closure and before rotational

force has been applied.

Table of Contents

- 9 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

3. Hold the container firmly and turn the device counter-clockwise to remove the closure. Stop

rotation once initial torque is complete but the tamper band has not yet broken. Rotation

should be slow and steady for the most accurate and repeatable results.

4. The initial torque is now displayed on the screen. Store this reading and zero the device (see

Section 3.4 above).

5. Continue counter-clockwise rotation until all tamper band bridges have broken. The band

break force will now be displayed on the screen. Store this reading and zero the device (see

Section 3.4 above). Make note of the reading location in memory to distinguish between the

two readings (initial vs. band break).

3.6 TorqTraQ®device menu

For devices shipped prior to November 2012, please see Section 11 Appendix – Legacy method of

operation.

The TorqTraQ®device has a number of functions which can be accessed while the device is powered

on. To access the menu from the measurement display, press the zero button three times quickly

(within a two second window). “Menu” will appear on the display. While in the menu, tapping the

button will scroll through the menu options. Each menu item will scroll across the display. To select an

option, press and hold the button for two seconds. Release the button when the display changes.

Some menu items will only be available when they are applicable. Some menu items can be enabled

and disabled, so the menu options will change accordingly (i.e. if the option is enabled, the menu item

will offer a “disable” option, and vice-versa).

1. Last Record Erase

If any measurements have been stored in the device, this option will erase the last

measurement from memory.

2. All Records Erase

If any measurements have been stored in the device, this option will erase all measurements

from memory. When this option is selected, the device will ask, “Are you sure?” Tap the zero

button until “Yes” is displayed, then press and hold the button for two seconds to erase all

records. Or, to cancel this option, tap the button until “No” is displayed, then press and hold

the button for two seconds to go back to the menu.

3. Alarm Disable / Alarm Enable

If an application or removal torque alarm has been enabled, this option will temporarily

disable the alarm until the next time the device is powered on. The alarm can be enabled in

the TorqTraQ®Desktop Software; please see Section 4.2 to set the alarms.

Table of Contents

- 10 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

4. Recording Disable / Recording Enable

This feature is for older devices that store every reading by default, and will not appear on

newer devices (see Section 11 Appendix – Legacy method of operation). This option prevents the

device from storing any more measurements until the next time the device is powered on,

thus allowing operators to stop storing readings temporarily so as to not fill up the memory.

5. Peak Hold Disable / Peak Hold Enable

By default, peak hold is enabled. Disabling peak hold prevents the device from holding peak

measurements on its display, thus the display will always show the instantaneous torque it is

measuring in real-time. Since the peak torque will not be held, recording will also be disabled

when peak hold is disabled. This option will remain in effect until the next time the device is

powered on. This feature is typically used to watch live readings while applying a closure.

6. Battery check

Displays the status of the device’s battery.

7. Last calibration date

Displays the date of the device’s last calibration.

8. Power off device

Powers off the device.

9. Exit menu

Exits the options menu and returns to measurement mode.

Table of Contents

- 11 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

4USING THE DESKTOP SOFTWARE

4.1 Main Screen

When the software opens, the main window appears. If devices are connected to the computer via

USB, they will be listed in the upper table labeled “Attached Devices”. If the device does not appear,

unplug the device from USB, plug it back in, then hit the “Refresh” button. If the device still does not

appear, then the device’s drivers are not installed properly.

This lower table lists archived records, which is described in Section 4.3 of this manual.

•Configure – This button enters the configuration window, allowing the user to view and change

the device’s parameters (refer Section 4.2).

•View Data – This button enters the data window, allowing the user to view, export, and erase

data currently stored on the device (refer Section 4.3).

•Validate – This button enters the validation window which guides the user through validation

using a certified object. Refer to Section 4.4. The validate feature requires software version

0.9.35 or greater.

•Refresh – This button searches for attached TorqTraQ® Devices.

•Exit – This button exits the software.

Table of Contents

- 12 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

4.2 Configure

•Serial – The device’s assigned serial number.

•Device Clock – The device’s internal date and time. See Section 2.3 to set the time on the

device.

•Last Calibration – When the device was last calibrated. More information regarding calibration

can be found in Section 8.

•Firmware Version – The current firmware version on the device. The device firmware may be

updated by clicking the Update button and selecting the *.bin file provided (usually by email or

CD).

•Model Number – The device’s model number, which relates to the available features on the

device.

•Mode of Operation – This changes how the device saves the data, and defines what action is

performed when using the Zero button. The default is Mode 2 which is covered in this manual.

Mode 1 is the legacy method of operation; please see Section 11 Appendix – Legacy method of

operation.

•Identifier – This user-modifiable field allows the device to be named by the operator. This

identifier displays when the device is powered on.

•Display Units – The selected unit of measurement defines what torque units are displayed and

reported by the device.

•Alarm Thresholds – When the alarm is enabled, it will produce a sound when the user-defined

torque level is reached. The set-points can be set independently for application and removal.

Setting either threshold to zero will disable the alarm.

•Alarm Type – The user can select the style of visual or audible alarm indicator.

oNone: Both alarms are disabled.

oBeep: A monotone beep that sounds when the measured torque is at or above the set-point.

oRing: A two-tone ring that sounds when torque is at or above the set-point.

oGeiger: The device will make a clicking sound which clicks faster the closer the measured

torque is to the set-point. Once the torque is at or above the set-point, it will beep.

oSilent: The device will not make an audible alarm, but the “Application” and “Removal” lights

will flash rapidly when torque is at or above the set-point.

Table of Contents

- 13 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

•Power Off Delay – If the device remains idle for this period of time, it will automatically shut

off.

•Load from Device – This button will retrieve the current settings from the device.

•Save to Device – This button will save the displayed configuration to the device.

•Close – This button closes the configuration window and returns the user to the Main Window.

4.3 View Data

This window displays the current data stored on the device. Selecting the column title box using the

left mouse button will sort the sample rows based on that column’s data. By default, the data is

sorted by record number (order in which data was stored in device).

•Refresh – This button refreshes the chart by reading the memory on the TorqTraQ® Device.

•Erase – This button erases the memory on the device. The user will be prompted to archive the

data prior to erasing it from the device. Once the data is archived, it will appear in the lower

window of the Main Window (see Section 4.1). Archived data is saved in a local database

managed by the TorqTraQ® software and can be accessed at a later date.

•Report (Export to Excel) – This button enters the report window, where the user will be able to

print or export the data. (see Section 4.3.1 for exporting data)

•Close – This button closes the data window and reverts back to the main window.

Table of Contents

- 14 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

4.3.1 Report screen (export to Excel)

This window displays a printable, organized report containing the data currently stored on the device.

This window is also accessible for archived data; archived data can be accessed from the Main

Window.

When exporting, use the Microsoft Excel options:

Table of Contents

- 15 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

4.4 Validate

For devices shipped prior to November 2012, please see Section 11 Appendix – Legacy method of

operation.

The validate feature requires software version 0.9.35 or greater.

This window guides the user through a device validation procedure using a certified object (referred to

as the “gold bottle” within the industry). This procedure allows users to confirm proper operation of

their equipment on a regular basis. In addition to providing average and standard deviation data on a

sample set, this screen allows the operator to perform an in-field calibration offset based on the

results. This does not modify the factory calibration and is reversible. The steps are outlined on the

screen to assist the operator; additional details for these steps are below.

1. Hit the Remove button found in the upper left corner to remove any existing offsets which may be

stored on the instrument

a. This is to prevent creating offsets “on top of” other offsets, which will not work

Optional: Clear any existing data from the instrument prior to testing the certified object

2. Take at least 15 readings in either the application or removal direction (or both). This size sample set is

required to perform in-field calibration offsets. The device can be unplugged during this time. When

testing is complete, plug the device back into the computer and hit the Refresh button.

3. Select the 15 data points from the list that correlates to measurements taken from the certified object.

Note: the most recent readings might require the user to scroll to the bottom of the list.

a. The user can only perform the offset one direction at a time; because of this, use the filter to

show either application or removal readings.

4. Optional: Enter the specification for the certified object and click the Apply Offset button. If Removal

readings were filtered and selected in the table, then the offset will be applied in that direction only.

5. Repeat the above steps for the opposite direction, if required (selecting the filter accordingly).

If the measured average deviates too far from the certified object, or the standard deviation is too

high, the software will not allow an in-field offset.

Table of Contents

- 16 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

5STORAGE

The TorqTraQ®Closure Testing Device should be stored in the provided carrying case. Storage

temperatures should not exceed 120°F (48°C). Do not stack heavy items on the device or storage case.

6CLEANING THE DEVICE

It is recommended that the TorqTraQ® device be cleaned on a regular basis, particularly if it is used in a

wet environment or on a package that contains liquid product (such as soft drinks or dairy products).

Product has the potential to seep into cracks and dry which can effectively glue components together,

making the device harder to service. To clean the device, spray a standard cleaning agent onto a soft

cloth towel or rag and wipe the exterior of the device. Cleaning agents with high alcohol content can

potentially haze the plastic top plate. Avoid vigorous wiping while using aggressive cleaning agents.

Standard cleanroom cleaning / wipe-down agents should be acceptable. DO NOT clean the device

directly with liquid; always use a moist cloth and dry afterwards.

There is a possibility for product (soda, milk, juice, etc) to seep behind and around the chuck. When

the product dries it can become sticky and potentially “glue” the chuck into place, making it very

difficult to remove. In some cases the chuck becomes damaged upon removal. If the packages being

tested contain a liquid product, it is recommended the operator coats the bottom and sides of the

chuck pocket with white lithium grease (or similar) prior to installing a chuck. Any excess grease should

be wiped off once the chuck is installed. The grease will fill the voids and keep the product from

seeping into cracks and drying.

7SAFETY NOTES

•Do not remove the top cover plate, or disassemble the TorqTraQ®device in any way.

•Do not use the TorqTraQ®device for any purpose other than its intended use.

•Always use mating chucks provided by the manufacturer. Do not attempt to fabricate mating

chucks or modify the mating chucks provided.

•Do not charge the TorqTraQ®device with anything other than the supplied charger or USB

cable.

If the safety instructions listed above are not followed properly, damage to the device may occur and

any warranties will be void.

Table of Contents

- 17 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

8SERVICE, WARRANTY, AND CALIBRATION

Warranty and Service:The TorqTraQ®device is covered under a one (1) year limited warranty. If the

device does not seem to be operating properly, please contact the manufacturer using the contact

information found in Section 10 of this manual. If the device needs sent in for service, please obtain a

Return Materials Authorization (RMA) number from the manufacturer (Section 10).

Calibration: The device is calibrated prior to delivery; it is recommended that the device be returned

to the manufacturer for calibration every 12 months. When calibration is due, the device will display an

alert during startup. If a TorqTraQ® device requires recalibration, please contact the manufacturer or

local distributor (Section 10) to obtain a current quote for this service. TorqTraQ® device calibrations

follow ASTM methods and are traceable to N.I.S.T. standards.

Table of Contents

- 18 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

9SPECIFICATIONS

- U.S. PAT #6,910,390 –

TorqTraQ® Device

Range (Application & Removal): 2.0 to 50.0 in·lb

Unit(s) of Measure: in·lb, ft·lb, in·oz, N·m, kg·M

User Selectable

Resolution: 0.1 in·lb

Accuracy / Linearity: ± 0.5% F.S. / ± 0.5% F.S.

Maximum Load: 100 in·lb

Internal Memory: 250 Samples

Alarm Thresholds: Adjustable (1.0 to 50.0 in·lb)

Storage & Operating

Temperature Range: 32°F to 120°F (0°C to 48°C)

Operating Humidity: < 95% R.H. Non-Condensing

Water-Resistance Rating: IPX4

Automatic Shut-Off: Adjustable (1-255 s)

Continuous Operation Time: > 9.0 Hours

Power Supply (for charging): Powered USB port or USB charger

Table of Contents

- 20 -

©2012 Plastic Technologies, Inc. - All Rights Reserved

11 APPENDIX – LEGACY METHOD OF OPERATION

Devices shipped prior to November 2012 operate with different firmware, meaning some of the

device functions are slightly different. These areas are indicated by the stop sign logo within

this manual. The differences in operation are outlined below.

To view what firmware version is loaded onto the device, see sections 4.1 and 4.2 of this manual.

If the firmware version listed in the configuration screen is greater than 1.0, this is a new release and

everything in sections 1-10 of this manual applies. Do not read on, this section does not apply.

If the firmware version listed in the configuration screen is less than 1.0, please see the changes

below.

Section 3.4 – Storing readings to memory

When a peak torque is displayed on the screen, momentarily (quickly) press the on/zero button to save

the reading and zero the device. All non-zero readings are stored in memory.

Section 3.6 – TorqTraQ® device menu

To access the menu, press and hold the on/zero button for two seconds.

Section 4.2 – Configure: Mode of operation

This option is only available for devices with firmware greater than 1.0. This option only appears in

software versions 0.9.35 or greater.

Mode 2 is the default for newer devices (shipped after November 2012). Sections 1-10 of this manual

are specific to Mode 2.

Mode 1 reverts newer devices to the legacy method of operation. This is for users who own both old

and new devices, and prefer the old method of operation.

Section 4.4 – Validate

This feature requires software version 0.9.35 or greater, and firmware version 1.0 or greater.

Table of contents

Popular Measuring Instrument manuals by other brands

Zehntner

Zehntner ZVR 6000 instruction manual

BASETech

BASETech EM-3000 operating instructions

TPI

TPI 285 instruction manual

STAUFF

STAUFF PPC-12 Quick start operating instructions

Flexitron

Flexitron webdyn MTX-StarEnergy-E Software user manual

Blue-White industries

Blue-White industries Sonic-Pro S6A Series operating manual