PROGRAMMING

1. Enter Program Mode (Passcode is 1997)

( press and hold each button until the dash appears)

To Program a Relay (pg. 27 of the manual)

Choose “Relay Type” (P210, 220)

0=Not in Use 1=Alarm 2=Control

(Alarm=de-energize ON and energize OFF, Control= is opposite)

Choose “Relay Function” (P211, 221)

0=Off 1=Level 4=Loss of Echo

Choose “Relay Setpoint 1” (P213, 223)

This is the ON setpoint.

Choose “Relay Setpoint 2” (P214, 224)

This is the OFF setpoint.

(no setpoints are required when “Loss of Echo” function is used)

To go to Run Mode, follow Step 3.

3. Calibration is done, go into Run Mode!!!

2. Choose “APP” (pg. 25 in manual)

Choose “Mode of Operation (P100)”

1=Distance 2=Level 3=Space 4=Volume

Choose “Measurement Units (P104)”

1=meters 2=cm 3=mm 4=feet 5=inches

Choose “Empty Level (P105)”

=distance from the transducer face to empty level (bottom of

vessel/pump station) - automatically sets 4mA

Choose “Span (P106)”

=distance from empty level (bottom of vessel) to 100% level

- automatically sets 20mA

Choose “Near Blanking Distance (P107)”

=distance from transducer face that is not measurable (can be

increased to blank out obstructions)

Choose “Far Blanking Distance (P108)”

=distance (in %) beyond Empty Level that is measurable

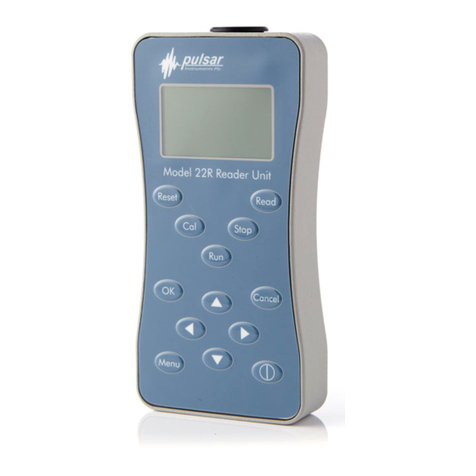

“rL”

Press both simultaneously,

“PASS” will display briefly,

then “0000” will appear.

For “1000”

For “1900”

For “1990”

For “1997”

This is the “Enter” button. Use the

“Enter”, “Up”, and “Down” buttons to

program the following parameters:

This is the “Esc” button. Use the “Esc”,

“Up”, and “Down” buttons to scroll

through the various categories:

“APP” (Application) “rL” (Relays) “Vol” (Volume)

“DisP” (Display) “LOOP” (mA Output)

“Cop” (Compensation) “StA” (Stability)

“SyS1” (System) “tESt” (Test) (scrolls back to APP)

“run”

Program Relay 1 (P210 - P214) and

then program Relay 2 (P220 - P224)

To Troubleshoot a false echo (pg. 40 of the manual)

To go to Run Mode, follow Step 3.

“SyS1” Displays “P921”.

Displays “P021” (Get out of Jail Free Card).

Enter the true distance from the transducer

face to the material level.

This will map out all false echoes and store

the information permanently.

IMP PC Software screen shot of echo profile