Contents

Chapter 1 Start Here… ....................................................................................................................................1

About thisManual...........................................................................................................................................1

About the Pulsarguard 201x series .................................................................................................................2

General Description.................................................................................................................................2

Product Range..........................................................................................................................................3

Options.....................................................................................................................................................3

Approvals.................................................................................................................................................4

Construction............................................................................................................................................. 5

Product Specification.......................................................................................................................................6

Physical....................................................................................................................................................6

Mounting................................................................................................................................................. 6

Environmental........................................................................................................................................6

Hazardous AreaApproval.....................................................................................................................6

Outputs.....................................................................................................................................................7

Supply......................................................................................................................................................7

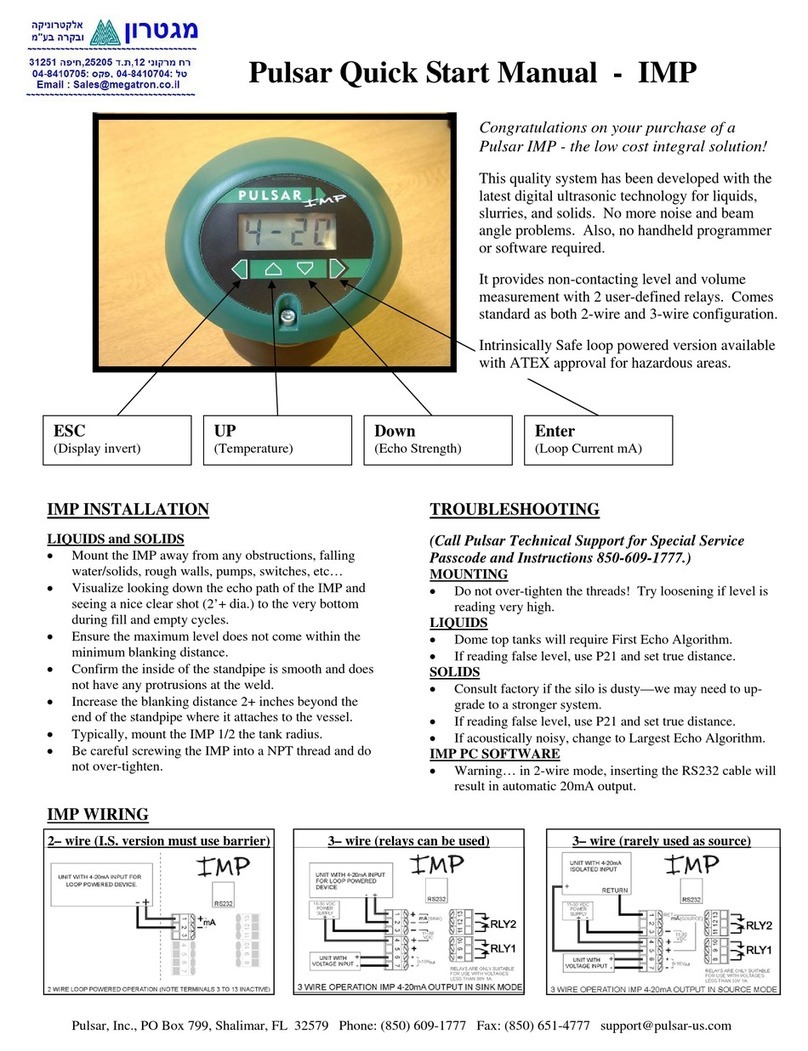

Chapter 2 Installation........................................................................................................................................9

Sensor Positioning...........................................................................................................................................9

Power Supply Requirements.........................................................................................................................10

Wiring Detail.................................................................................................................................................10

Instructions specific to hazardous area installations.....................................................................................11

Identification:.......................................................................................................................................12

EU DECLARATION OF CONFORMITY.......................................................................................................15