■ Storage method

■ Checks after unpacking the carton

■ General

■ Precautions for use

SENERGY Motor Roller (DC-24V) Installation Manual

NOTE: Control card is not contained. Please purchase it separately.

Thank you for purchasing SENERGY Motor Roller. These instructions contain important information to enable you to use

the products safely and to prevent any harm or damage to you and others. Familiarize yourself with the content before

using the products. After reading this manual, be sure to keep in the assigned place.

● Do not use this product in an explosive atmosphere, flammable gas atmosphere, corrosive atmosphere, a place exposed to water

splashes, or a place close to combustibles. It may cause an explosion, injury, or fire. (Use the waterproof type when the product is

exposed to water splash environment.)

● After confirming the DC power supply, supported voltages and specifications of the Motor Roller, connect them carefully not to make a

mistake.

● Do not conduct such operations as move, installation, connection, and inspection while the power is on. Be sure to conduct such

operations after turning off the power in order to be safe from electric shock.

● Do not use Motor Roller in any way beyond its specifications. It may cause an injury or fire.

● Be sure to ground the frame of the conveyor / equipment.

● Determine the number of Motor Rollers in consideration of the performance/characteristics.

(The motor will generate heat when used in an overload condition, resulting in a shorter product life-cycle.)

● Handle the Motor Rollers with care because the surface temperature of the tube can be high depending on the conditions of use.

● Do not repair, alter, or disassemble Motor Rollers. It may cause an electric shock, injury, or failure.

● Use the Motor Roller in the usage environment of ambient temperatures ranging from -10 to +40°C and relative humidity ranging from

10 to 90% (non condensing).

● Do not apply strong impact, such as dropping or striking the Motor Roller.

● Do not carry the Motor Roller by holding the cable, and do not pull or replace the connector. Be careful not to damage the wire-coating

while drawing the cable through fixing parts and frame.

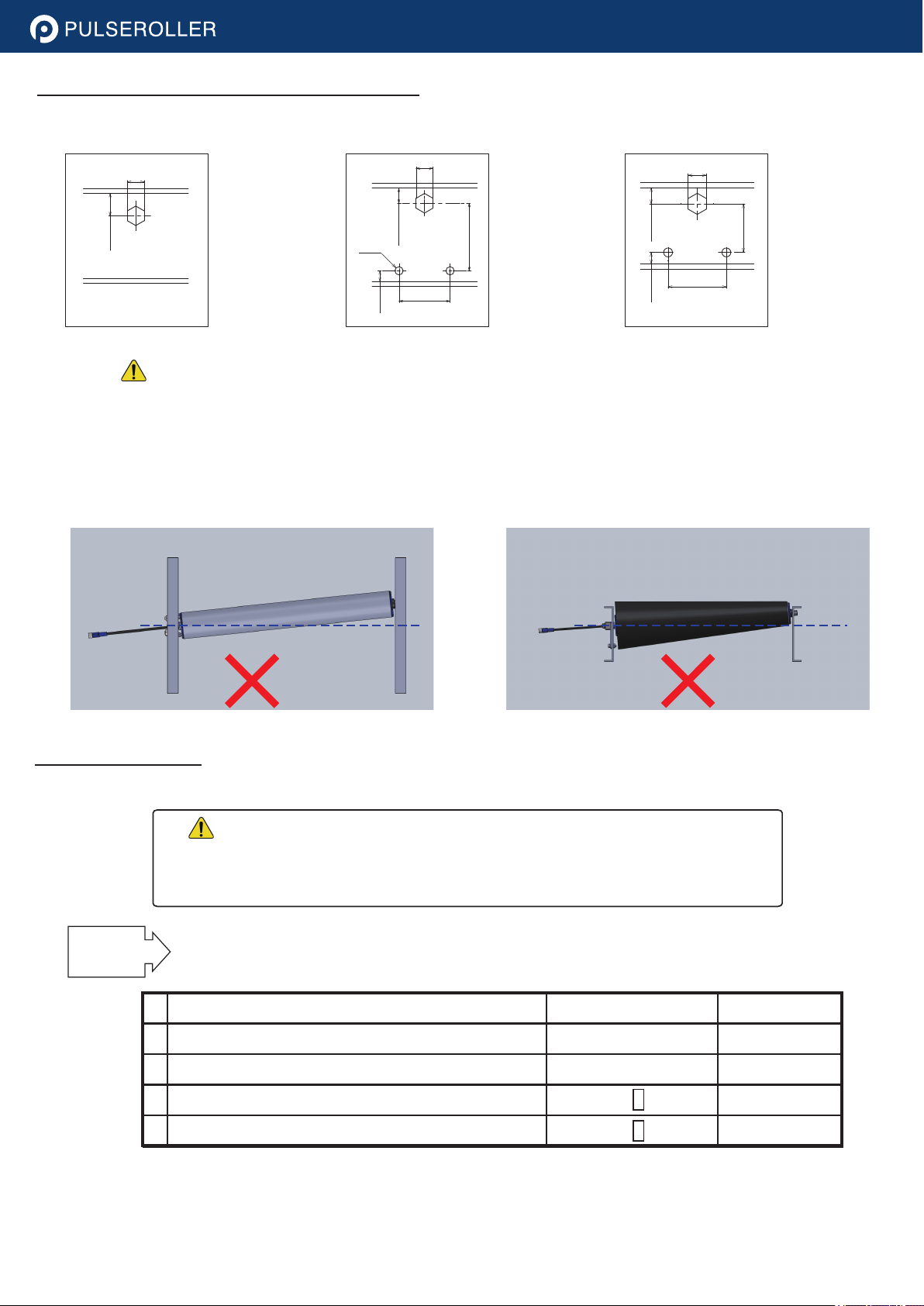

● Mount the Motor Roller and idler rollers in the same level so that they are evenly loaded.

● Never store or leave the Motor Roller outdoors. (It may cause a short circuit or rust.)

● Store the Motor Roller in the environment of ambient temperatures ranging from -30 to +40°C and relative humidity ranging from

10 to 90% (non condensing).

● Store the Motor Roller horizontally because grease is enclosed inside.

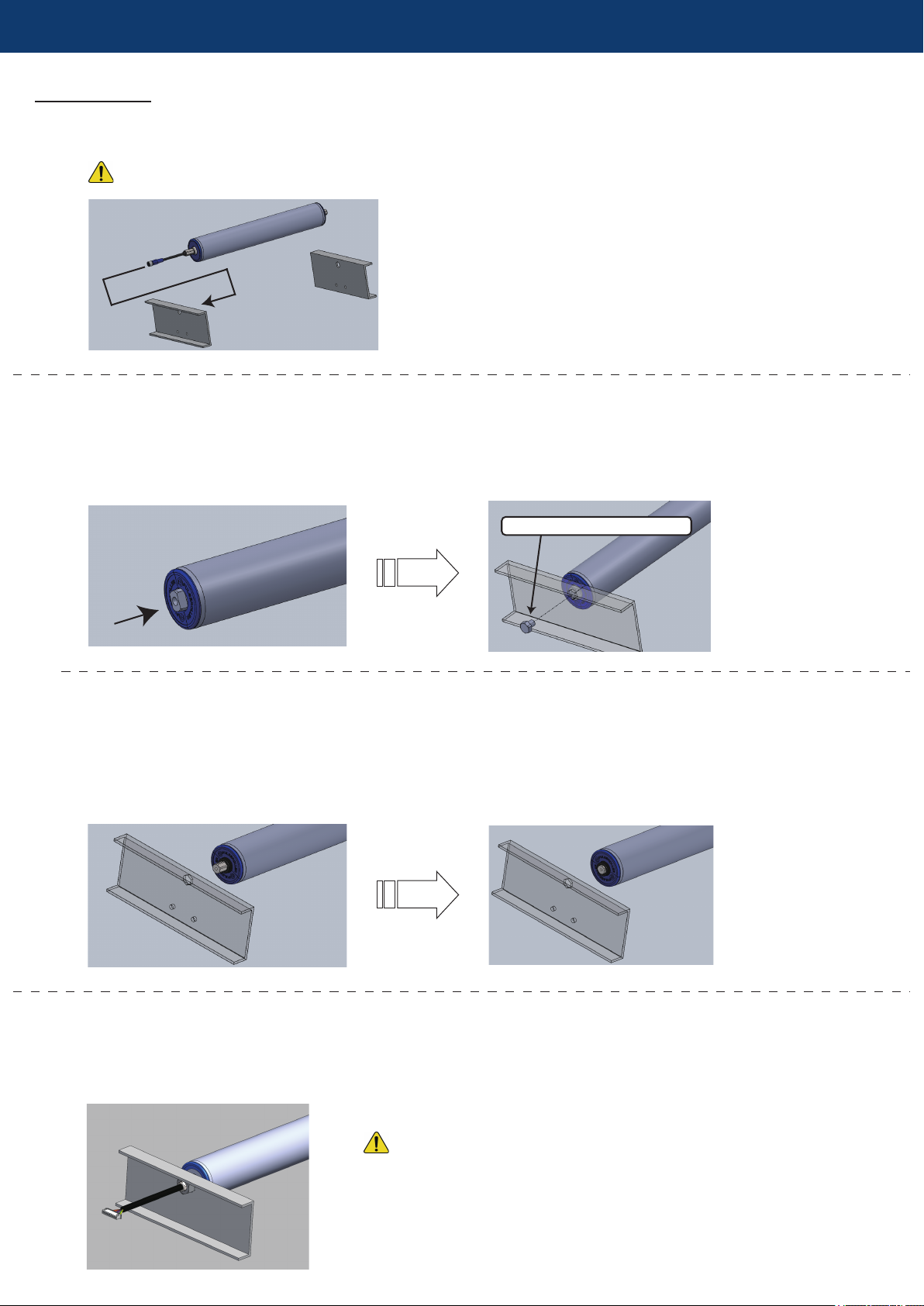

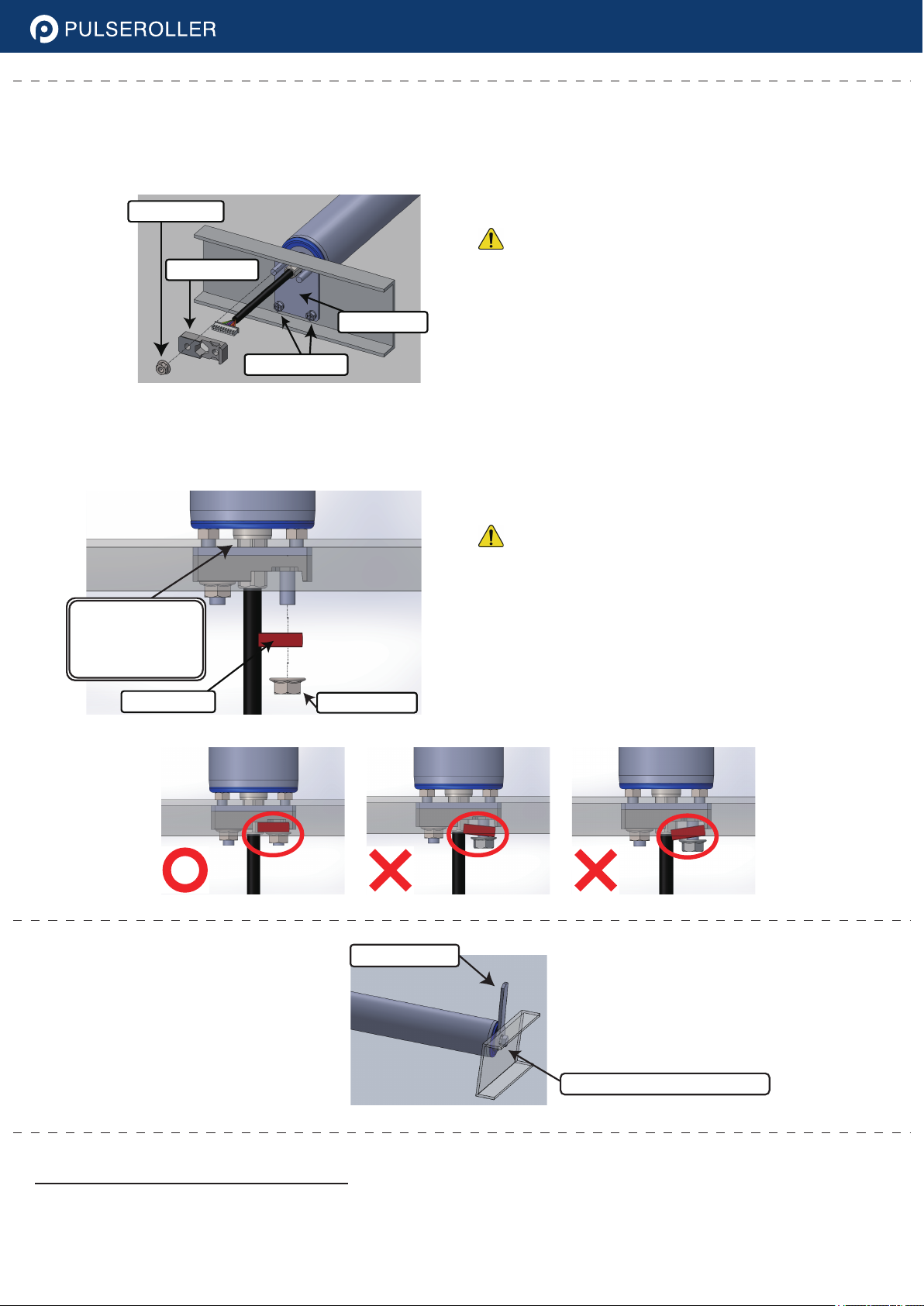

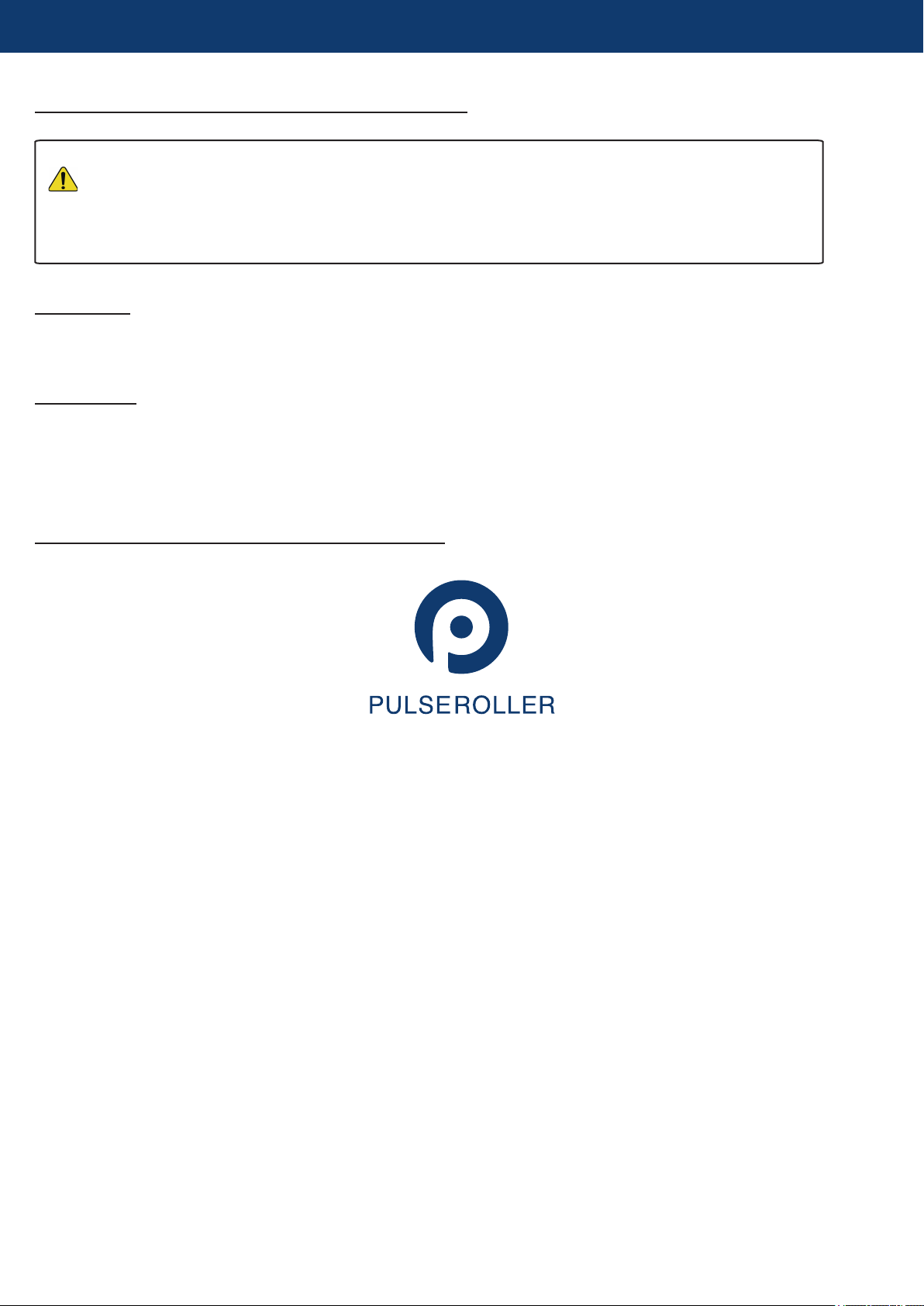

(1) Check the product label on End-plate at the cable side of the Motor Roller to confirm that Part number matches to your order.

(2) Check that 1 Fixing parts set is included per Motor Roller. (In case of threaded shaft spec, Nut and Washer are included.)

(3) Check the type and Part number of Fixing parts.

Warning: indicates a potentially hazardous situation, which may result in death or serious injury if improperly handled/used.

Caution: indicates a potentially hazardous situation, which may result in injury or property damage if improperly handled/used.

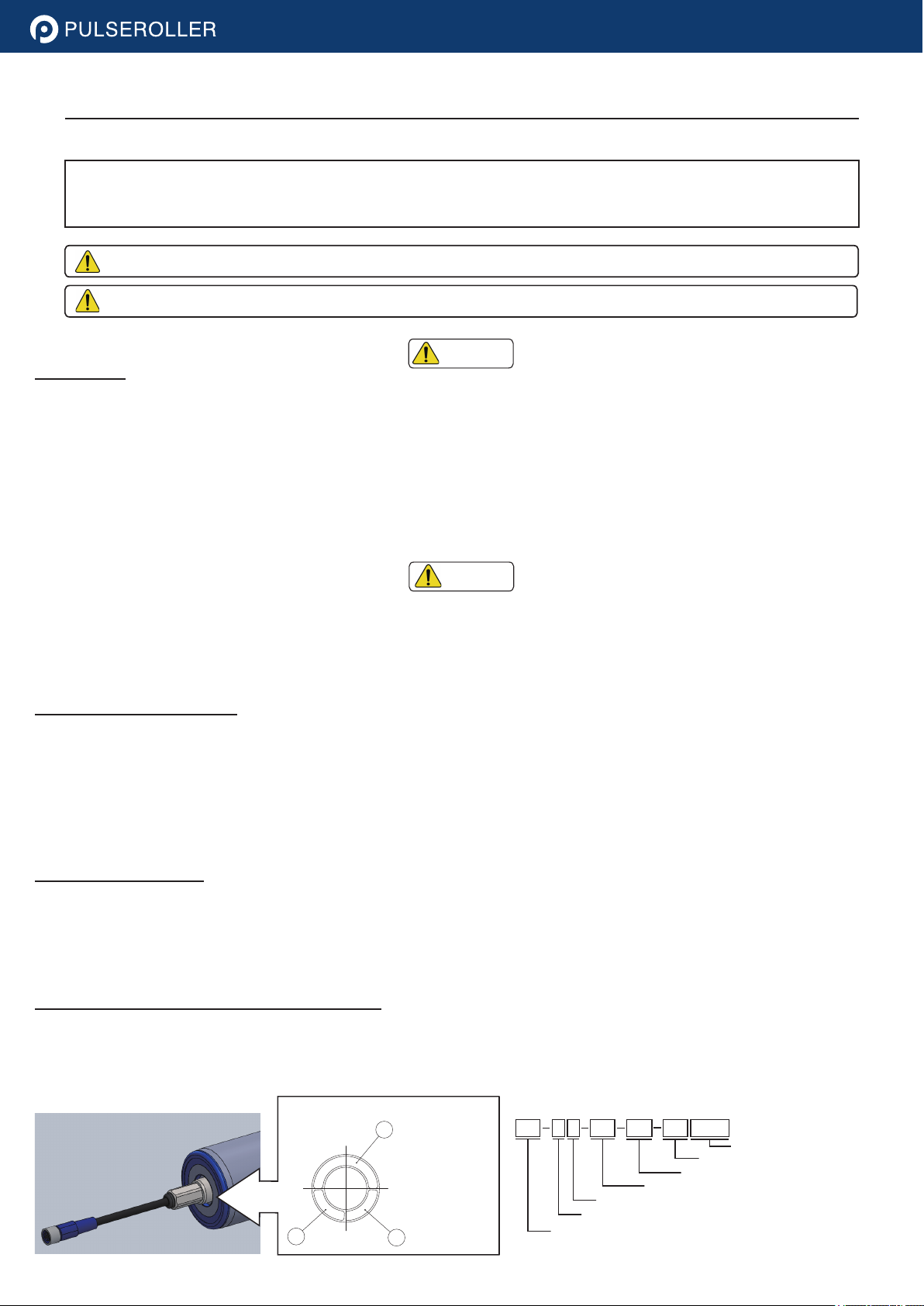

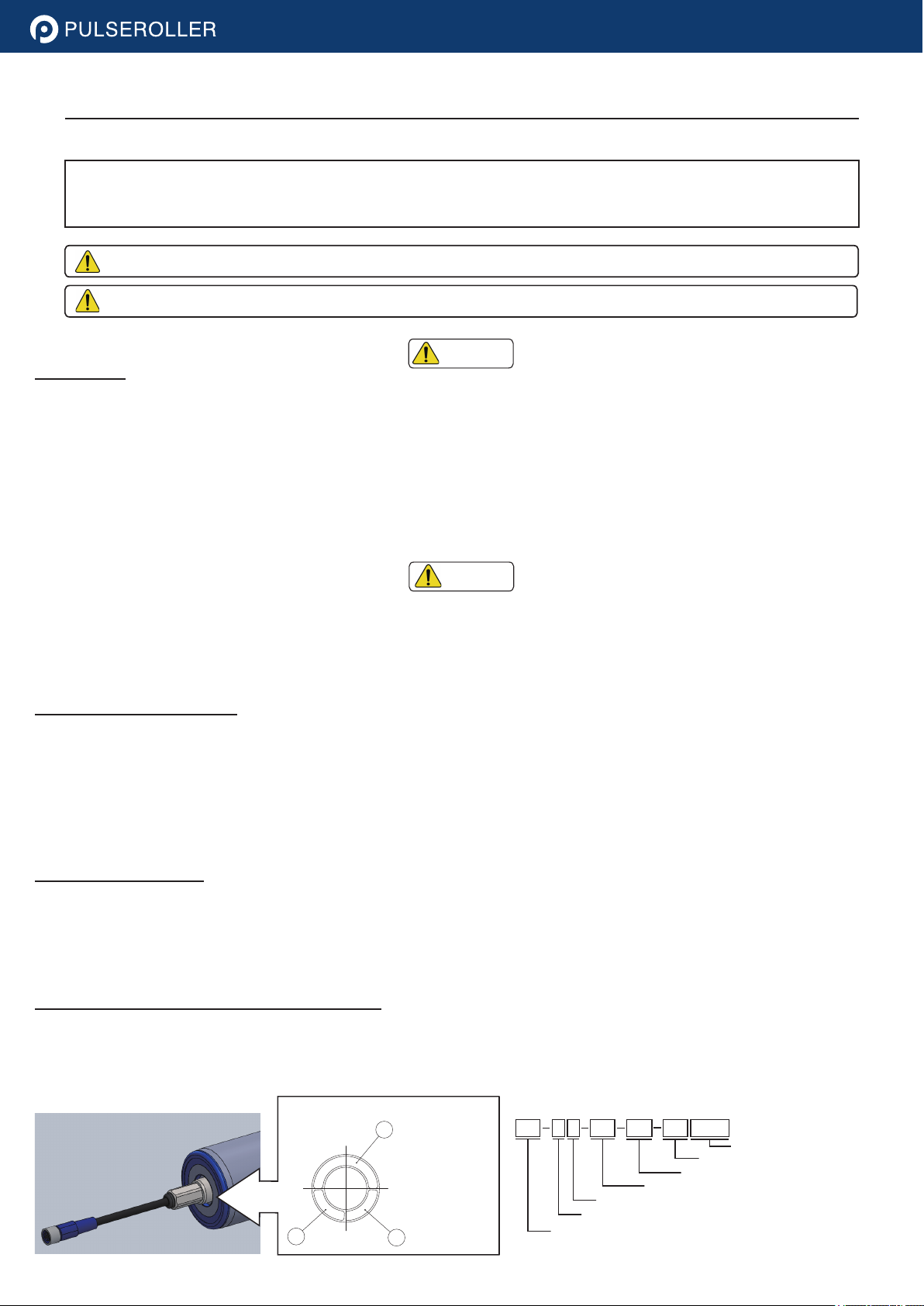

<Label Example>

*For the details of the fields marked with '*', refer to the catalog.

(1) Product Part

number

(2) Power supply

voltage

(3) Serial number

1

0

0

1

0

A

1

D

C

2

4

V

3

F

A

S

A

0

6

-

0

0

5

-

8

4

-

D

A

-

R

P

1

2

3

X

X

X

<Example of Part Number>

PR A D 50 500 60 ZMAT

*Various specifications

Speed code

Roller length

Diameter

DC24V

*Specification

Abbr. of PULSE ROLLER

<Label Example>

Warning

Caution