TLV RGDS User manual

172-65608MA-03 (RGDS) 5 October 2021

Steam Desuperheating System

RGDS

Copyright © 2021 by TLV CO., LTD.

All rights reserved

172-65608MA-03 (RGDS) 5 Oct 2021

1

Contents

Contents............................................................................1

Introduction .......................................................................1

Safety Considerations.......................................................2

System Control..................................................................4

System Features...............................................................4

System Specifications.......................................................5

System Description ...........................................................6

Installation.........................................................................7

Pre-commissioning Verification.......................................10

Normal Operation and Shutdown Procedures ................11

Maintenance and Inspection...........................................13

Troubleshooting ..............................................................15

TLV EXPRESS LIMITED WARRANTY...........................19

Service ............................................................................21

Introduction

Thank you for purchasing the TLV steam desuperheating system RGDS.

This system has been thoroughly inspected before being shipped from the factory.

When the product is delivered, before doing anything else, check the specifications

and external appearance to make sure nothing is out of the ordinary. Also be sure to

read this manual carefully before use and follow the instructions to be sure of

installing and using the system properly by following the installation and operating

procedure.

After the completing the installation work, our technical personnel will explain the

commissioning and operation of this system. Please keep this manual,

commissioning report, specification and all documents related to this system for

further reference.

There are some cases on which this manual does not include instructions

concerning individual special specifications but instead refers to other manuals.

For further details please contact your closest TLV office.

This instruction manual is intended for use with the system listed on the front cover. It

is necessary not only for installation but for subsequent maintenance,

disassembly/reassembly and troubleshooting. Please keep it in a safe place for

future reference.

172-65608MA-03 (RGDS) 5 Oct 2021

2

Safety Considerations

Read this section carefully before use and be sure to follow the instructions.

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

The precautions listed in this manual are designed to ensure safety and prevent

equipment damage and personal injury. For situations that may occur as a result of

erroneous handling, three different types of cautionary items are used to indicate

the degree of urgency and the scale of potential damage and danger: DANGER,

WARNING and CAUTION.

The three types of cautionary items above are very important for safety: be sure to

observe all of them as they relate to installation, use, maintenance, and repair.

Furthermore, TLV accepts no responsibility for any accidents or damage occurring

as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

Indicates an urgent situation which poses a threat of death or

serious injury

Indicates that there is a potential threat of death or serious injury

Indicates that there is a possibility of injury or equipment/product

damage

In the event of any abnormality, stop the system and utilities

supply (steam, water, air and electricity). Investigate the cause

of the abnormality and take countermeasures.

Forbid the supply of utilities to the system until the countermeasures

have been implemented.

Install properly and DO NOT use this system outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the system

or malfunctions that may lead to serious accidents. Local

regulations may restrict the use of this system to below the

conditions quoted.

Use hoisting equipment for heavy objects (weighing

approximately 20 kg (44 lb) or more).

Failure to do so may result in back strain or other injury if the object

should fall.

Take measures to prevent people from coming into direct

contact with system outlets.

Failure to do so may result in burns or other injury from the

discharge of fluids.

Continued on the next page

DANGER

WARNING

CAUTION

WARNING

CAUTION

172-65608MA-03 (RGDS) 5 Oct 2021

3

When disassembling or removing the system, wait until the

internal pressure equals atmospheric pressure and the surface

of the system has cooled to room temperature.

Disassembling or removing the system when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

Be sure to use only the recommended components when

repairing the system, and NEVER attempt to modify the system

in any way.

Failure to observe these precautions may result in damage to the

system and burns or other injury due to malfunction or the discharge

of fluids.

Do not use excessive force when connecting threaded pipes to

the system.

Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no water hammer will

occur.

The impactof water hammer maydamage the system, leadingtofluid

discharge, which may cause burns or other injury.

Make sure the power supply is OFF before carrying out work

on the wiring or inspections involving disassembly.

If such work is carried out with the power on, there is a danger that

components may malfunction or electric shock may occur, leading

to injury or other accidents.

Make sure that installation work requiring a special license is

carried out by qualified personnel.

Improper work may cause falls, dropped items, overheating and

electrical leaks, leading to injury, burns, fires, damage and other

accidents.

When using this system, NEVER stand close to, or leave tools

anywhere near moving parts, such as the shaft.

Contact with moving parts or objects becoming caught in moving

parts could lead to injury, damage or other accidents.

This system is composed of steam devices and piping.

Insulate the system properly to prevent burns and heat loss.

After all piping work has been performed according to the

system flow diagram, check that all connections are tightened,

all gaskets have been installed and for unsecure installations.

Improper piping work may lead to discharge of fluids, causing burns,

other injuries or damage.

Do NOT touch terminals when power is on.

This may lead to system breakages, erroneous operation,

electrical shock or fires.

CAUTION

172-65608MA-03 (RGDS) 5 Oct 2021

4

System Control

Use only under conditions in which no water hammer will occur. The

impact of water hammer may damage the system, leading to fluid

discharge, which may cause burns or other injury.

CAUTION

The TLV desuperheating system consists of three main parts,

Pressure reducing section, used to regulate steam pressure to the desired

setting value by a pressure control loop, as a result the steam pressure

stabilizes, which leads to a stable steam temperature.

Desuperheating section, consists of temperature control valves and injector with

nozzles, used to inject the cooling water in to the steam flow in order to reduce

the temperature of the steam. Feed control valves actuated though a

temperature control loop regulate the water volume injected for temperature

reduction.

Water mixing and separation section, consist of static mixer and condensate

separator, in order to desuperheat (reduce the temperature) from the steam with

the cooling water, by passing the flow through (2) static mixers connected in

series and later on through a cyclone separator to remove the excess water that

could exist.

System Features

The following are some features of the desuperheating system (RGDS) from TLV.

Stable and steady steam pressure supply

The spray nozzle used for water injection has a very fine tip in order to ensure

the spray absorbs the most heat in a shorter distance. Furthermore the heat

absorption effect is improved by forcibly mixing the flow with a static mixer.

In the unlikely event that any excess water is injected, it is forcibly removed by

condensate separators, so this excessive water will not flow into the downstream

of the system. As a result, the prevention of water hammer and stable heating

are achieved.

172-65608MA-03 (RGDS) 5 Oct 2021

5

System Specifications

Install properly and DO NOT use this system outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the system or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this system to below the conditions quoted.

CAUTION

Item

Property

RGDS (Standard

Specification)

Ex-proof

Specification

Pressure

Reducing

Section

Steam Control

Valve

Model

CV101)

(Non Ex-proof)

CV101)

(Exd II BT5)

Size/Connection

Depends on specifications

Pressure

Sensor

(With Siphon)

Model

MBS33M1)

(Non Ex-proof)

KD431)

(Exd II BT4)

Size/Connection

R 3/8

R 1/2

Desuperheating

Section

Temperature

Control Valve

Model

CV101)

(Non Ex-proof)

CV101)

(Exd II BT5)

Size/Connection

Depends on specifications

Temperature

Sensor

Model

TR1-35S1)

R1G1) (d2G4)

Connection

R 3/8

R 1/2

Strainer

Model

Y31)

Size/Connection

Depends on specifications

Check Valve

Model

CKF3M1)

Connection

Flangeless (wafer) type

Size depends on specifications

Water Mixing

and Separation

Section

Water

Injector,

Static Mixer

Size/Connection

50 –200 mm (2 –8 in): JIS 10K,

20K, 30K, ASME/JPI Class 150, 300

Condensate

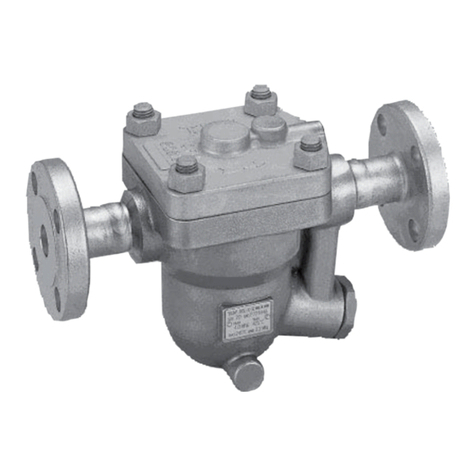

Separator

Model

DC3

Size

50 –150 mm (2 –6 in)

(For 200 mm (8 in) water

injector/static mixer, 150 mm (6 in)

separators installed in parallel)

Steam Trap

Model

JS-X series, JH series

Size/Connection

Depends on specifications

Pump Section2)

Pump

Model

CRN1)

(Non Ex-proof)

CRN1)

(eG3, d2G4)

Size/Connection

Depends on specifications

Control Panel

Power rating

200 V

Special order

Installation

Location

Indoor

Outdoor

Installation Type

Wall-

mounted

Stand-

alone

Pressure Range

0 to 1.6 MPaG (0 to 250 psig)

Minimum Set Temperature

5 C (10 F) above saturated steam temperature

(Size 200 mm (8 in): 10 C (20 F) above saturated

steam temp.)

Steam Supply Temp. Stability

Within 1 C (1.8 F)3)

Steam Velocity

5 to 50 m/s (20 to 160 ft/s)

Steam Discharge

200 to 30,000 kg/h (450 to 66,000 lb/h)

1) Standard products when the components are supplied by TLV. The model type may differ

depends on the installation environment.

2) This device is required when the pressure of the desuperheating water supplied to the

system is insufficient.

3) This value depends on the status of the process as well as the PID setting and is only to be

used as a reference.

For details regarding components, refer to the individual specification data sheets (SDS).

172-65608MA-03 (RGDS) 5 Oct 2021

6

System Description

Install properly and DO NOT use this system outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the system or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this system to below the conditions quoted.

CAUTION

The TLV standard desuperheating system (RGDS) consist of three sections:

Pressure reducing section, desuperheating section and water mixing and separation

section.

Note: a pump section is required when the desuperheating water pressure is

insufficient.

Section

Component

Description

Pressure reducing

section

A

Pressure control valve

The pressure control valve reduces

the steam pressure as required.

B

Pressure sensor

Desuperheating

section

C

Temperature control

valve

The temperature control valve

reduces the steam temperature as

required.

The strainer prevents clogging of the

water injector’s internal nozzle by dirt,

rust and scale.

The check valve reduces the risk of

water hammer due to steam flowing

into the desuperheating water line.

D

Temperature sensor

E

Strainer

F

Check valve

Water mixing and

separation section

G

Water injector

Injects water and mixes it with steam

for desuperheating. Discharges

excess desuperheating water via the

separator.

The steam trap discharges

condensate from the separator and

excess desuperheating water.

H

Static mixer

I

Condensate separator

J

Steam trap

(F)

Desuperheating Section

Water Mixing & Separation Section

Pump Section

Pressure Reducing Section

Pit

Max. 30 m (98 ft)

(B) (D)

(A)

(K)

(I)

(H)

(G)

(C)

(E)

Desuperheating

water

Minimum

flow

Superheated

steam Desuperheated

steam

Condensate

recovery

Required length:

1.5 m (5 ft)

In case of two-stage pressure reduction, make

sure to keep at least 1 m (3 ft) between the first

and second pressure reducing valve.

Safety

valve

(J)

Control

box

1/100 to 1/200

Required straight piping

length: See “Minimum

required straight piping

length by nominal

diameter” on page 8.

172-65608MA-03 (RGDS) 5 Oct 2021

7

Installation

Install properly and DO NOT use this system outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the system or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this system to below the conditions quoted.

CAUTION

Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more). Failure to do so may result in back strain or other

injury if the object should fall.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Do not use excessive force when connecting threaded pipes to the

system. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Make sure that installation work requiring a special license is carried out

by qualified personnel. Improper work may cause falls, dropped items,

overheating and electrical leaks, leading to injury, burns, fires, damage

and other accidents.

CAUTION

After all piping work has been performed according to the system flow

diagram, check that all connections are tightened, all gaskets have

been installed and for unsecure installations. Improper piping work may

lead to discharge of fluids, causing burns, other injuries or damage.

CAUTION

This system is composed of steam devices and piping.

Insulate the system properly to prevent burns and heat loss.

CAUTION

Pressure Reducing Section

Ensure the distance between the pressure

reducing valve and the pressure control valve (A)

is 30 d or more when reducing supply steam on the

primary side of the control valve (A).

Desuperheating Section

1. The piping distance from the temperature

control valve (C) outlet to the injector (G)

nozzle should be as short as possible in order

to reduce pressure losses.

2. Install the temperature sensors (D) so that the

sensor portion is inserted into the piping.

Sensor Portion

Piping

Pressure

Reducing Valve Pressure Control

Valve (A)

30 d or more

d = Pipe diameter

Temp. Control

Valve (C)

Water Injector (G)

30 m (98 ft)

or less

172-65608MA-03 (RGDS) 5 Oct 2021

8

Water Mixing and Separation Section

1. Make sure the piping between the injector (G) and the temperature sensors (D) is

straight and horizontal. Do not install other devices such as check valves and

strainers that could cause a pressure drop.

2. Ensure the piping between the injector (G) and the condensate separator (I) is at

a slight decline (between 1:100 and 1:200) and is of the required straight piping

distance.

Minimum required straight piping length by nominal diameter

Pipe

size/DN

mm

50

65

80

100

125

150

200

(in)

(2)

(21/2)

(3)

(4)

(5)

(6)

(8)

Length

m

(ft)

4.5

(15)

5.5

(9)

6.5

(22)

7.5

(25)

10

(33)

3. The injector (G) and static mixer (H) each have an installation direction.

Installation in the wrong direction will prevent the equipment from functioning as a

desuperheater.

a) There is a circular engraving on top of

the injector body (G) (see right). Make

sure this engraving is on the

downstream side of the injector when

installing the desuperheating water

piping.

b) The static mixer (H) is shipped as two

separate pipe-shaped products.

Each static mixer has a flow direction

indicated on the flange (L = Left, R =

Right). Make sure the second mixer starts

with the same direction as the first mixer, i.e. “LR-LR”and “RL-RL”.

Note: “L”and “R”do not denote upstream and downstream.

In addition, make sure the static mixer flange faces meet so that the internal

mixer partitions meet at right angles to each other at the flange face.

There is no restriction on the direction the mixer partitions face in the end of

the flanges on the upstream and downstream sides.

4. Ensure the steam trap (J) on the condensate outlet of the injector (I) is installed in

a location where inspections and maintenance can be performed.

Allowable inclination:

1:100 to 1:200

Required straight

piping distance

Condensate

Separator (I)

Static Mixer (H)

Water Injector (G)

Upstream Downstream

Engraving

Mixer partitions

172-65608MA-03 (RGDS) 5 Oct 2021

9

Other

Carefully consider the following items if installing a pump.

1. Install piping supports on the suction side and discharge side of the pump (K) and

make sure there is no load on the pump body.

2. Install flexible tubing on both the suction side and discharge side of the pump (K),

to prevent vibrations from the pump from transmitting through the piping.

Make sure to use vibration absorbing type flexible tubing for use with pumps.

3. Install a strainer to prevent foreign matter from entering the suction side of the

pump (K).

4. Set a minimum flow line for the pump (K) and make sure not to operate the pump

under shut-off conditions.

172-65608MA-03 (RGDS) 5 Oct 2021

10

Pre-commissioning Verification

Install properly and DO NOT use this system outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the system or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this system to below the conditions quoted.

CAUTION

After all piping work has been performed according to the system flow

diagram, check that all connections are tightened, all gaskets have

been installed and for unsecure installations. Improper piping work may

lead to discharge of fluids, causing burns, other injuries or damage.

CAUTION

Checking the System

1. Preparation

1.1 Items to prepare

System equipment list

Flow diagram

Product specifications

Control box diagrams, terminal connection diagrams, sequence diagrams

Applicable equipment documents (drawings, specifications etc.)

Instruction manuals for each products

1.2 Items to verify

Verify whether commissioning can be performed.

Installation progress (verify whether piping and wiring installation is

complete)

Utilities (verify whether steam, water and electricity are supplied)

Personnel from user’s side to witness the commissioning (ensure at least

one person is present)

Process for maintenance work in the event of a problem, or preparations

for such work

Preparations for the load (steam venting) for steam control adjustment

Note: Commissioning should be conducted with TLV personnel present.

172-65608MA-03 (RGDS) 5 Oct 2021

11

Normal Operation and Shutdown Procedures

Operating Procedures: Pressure Reducing Section

2. Pressure reducing section

2.1 Preparation

1. Supply electricity and air to the system.

2. Turn on the power for the control box.

3. Check whether the pressure sensor values are normal.

4. Check whether the valves before and after the system are open.

2.2 Verification for manual operation

1. Open the pressure control valve manually to 10%.*

(Verify that steam has started to flow.)

2. Wait 5 minutes for the hot air in the steam piping to be discharged.

3. Slowly open the pressure control valve (at a rate of approximately 10%

per 2 minutes), until the indicated pressure is approximately 0.2 MPaG

less than the target value.

* If superheated steam cannot be supplied to the steam-using equipment side,

perform the operating procedures for the desuperheating section in parallel with the

operating procedures for the pressure reducing section.

2.3 Verification for automatic operation

1. Verify that the pressure has reached approximately 0.2 MPaG less than

the target value and switch to automatic operation.

2. Verify that the steam pressure is stable at the target value.

Operating Procedures: Desuperheating Section

3. Pressure reducing section

3.1 Preparation

1. Supply electricity, air and water to the system.

2. Turn on the power for the control box.*

3. Check whether the temperature sensor values are normal.

4. If a pump is installed, start operating the pump.

5. Check whether the valves before and after the system are open.

3.2 Verification for manual operation

1. Open the temperature control valve manually to 10%.*

(Verify that steam has started to flow.)

2. Slowly open the temperature control valve (at a rate of approximately 10%

per 2 minutes), until the indicated temperature is approximately 10 °C less

than the target value.

3.2 Verification for automatic operation

1. Verify that the temperature has reached approximately 10 °C less than the

target value and switch to automatic operation.

2. Verify that the steam temperature is stable at the target value.

Check visually that the amount of condensate discharged by the separator is

normal.

* Unnecessary if sharing the same control box as the pressure reducing section.

172-65608MA-03 (RGDS) 5 Oct 2021

12

Shutdown Procedures: Pressure Reducing Section

1. Slowly close the pressure reducing valve (approximately 10% per 2 minutes).

2. Verify that the pressure reducing valve is fully closed, and then close the manual

valve on the primary side of the pressure reducing valve.

3. Turn off the power for the control box.*

* Unnecessary if sharing the same control box as the pressure reducing section.

Shutdown Procedures: Desuperheating Section

1. Verify that the pressure reducing section has stopped. If a pump is installed, stop

the pump.

2. Close the temperature control valve fully.

3. Verify that the temperature control valve is fully closed, and then close the

manual valve on the primary side of the temperature reducing valve.

4. Stop the electricity supply for the control box and close the valves for the air

supply to the control valve instruments.

172-65608MA-03 (RGDS) 5 Oct 2021

13

Maintenance and Inspection

When disassembling or removing the system, wait until the internal

pressure equals atmospheric pressure and the surface of the system has

cooled to room temperature. Disassembling or removing the system

when it is hot or under pressure may lead to discharge of fluids, causing

burns, other injuries or damage.

CAUTION

Be sure to use only the recommended components when repairing the

system, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the system or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Make sure the power supply is OFF before carrying out work on the

wiring or inspections involving disassembly. If such work is carried out

with the power on, there is a danger that components may malfunction

or electric shock may occur, leading to injury or other accidents.

CAUTION

Make sure that installation work requiring a special license is carried out

by qualified personnel. Improper work may cause falls, dropped items,

overheating and electrical leaks, leading to injury, burns, fires, damage

and other accidents.

CAUTION

When using this system, NEVER stand close to, or leave tools anywhere

near moving parts, such as the shaft. Contact with moving parts or

objects becoming caught in moving parts could lead to injury, damage

or other accidents.

CAUTION

Periodically inspect and check the following items as preventive maintenance.

For details regarding maintenance considerations, refer to the individual instruction

manual for each component.

Maintenance Checklist

To promote trouble-free operation of the system, inspections and maintenance of the

following items should be carried out periodically.

Injector pump

Daily inspection

Leakage from pump mechanical seal

Abnormal sounds from the pump or motor

Values indicated by the pressure/temp. gauges

Monthly inspection,

maintenance point

Pump suction pressure changes

Cracks in the tank and piping or water leakage

When there is a risk of freezing or the system will not be used for

a long time, water must be blown from the tank and pump interior

Valves

Daily inspection

Leakage from the valve body

Control valve air pressure and valve aperture

Annual inspection

Disassemble and clean the control valves

Other accessories

Daily inspection

Values indicated by the pressure/temp. gauges

Monthly inspection,

maintenance point

Disassemble and clean Y strainers, blow strainers with

condensate blow valves

Steam trap and condensate separator operation

Spray nozzle is not blocked

172-65608MA-03 (RGDS) 5 Oct 2021

14

Replacement Timing for Consumables

Refer to the following table as a guide for the timing to replace consumable parts.

Part

Replacement Timing

Pump

Mechanical seal

When liquid leakage is observed or after 8000 hours

operation

Shaft, bearings

Every 2 to 3 years

Gaskets

When liquid leakage is observed or when disassembling

Refer to individual instruction manuals for other maintenance and inspection procedures.

172-65608MA-03 (RGDS) 5 Oct 2021

15

Troubleshooting

In the event of any abnormality, stop the system and utilities supply

(steam, water, air and electricity). Investigate the cause of the

abnormality and take countermeasures. Prevent the supply of utilities to

the system until the countermeasures have been implemented.

WARNING

Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more). Failure to do so may result in back strain or other

injury if the object should fall.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

When disassembling or removing the system, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the system

when it is hot or under pressure may lead to discharge of fluids, causing

burns, other injuries or damage.

CAUTION

Be sure to use only the recommended components when repairing the

system, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the system or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Make sure the power supply is OFF before carrying out work on the

wiring or inspections involving disassembly. If such work is carried out

with the power on, there is a danger that components may malfunction

or electric shock may occur, leading to injury or other accidents.

CAUTION

Make sure that installation work requiring a special license is carried out

by qualified personnel. Improper work may cause falls, dropped items,

overheating and electrical leaks, leading to injury, burns, fires, damage

and other accidents.

CAUTION

When using this system, NEVER stand close to, or leave tools anywhere

near moving parts, such as the shaft. Contact with moving parts or

objects becoming caught in moving parts could lead to injury, damage

or other accidents.

CAUTION

Do NOT touch terminals when power is on. This may lead to system

breakages, erroneous operation, electrical shock or fires.

CAUTION

When the system fails to operate properly, use the following table to locate the cause

and remedy.

Item

Cause

Diagnostic

Remedy

The pump

does not start

A current is not

applied to the

pump

The power is not turned on

Turn on the power

The wiring is disconnected or not

connected

Connect the wiring

The power is cut off

Apply current to the

pump

The non-fuse

breaker is

operating

There is a short in the sequence

Fix the control system

then reset the non-

fuse breaker

The pump

cannot be

activated

A thermal relay has tripped or the

wiring is disconnected

Disassemble and

clean the pump

If the motor is broken,

replace the motor

Reset the thermal

relay

Continued on the next page

172-65608MA-03 (RGDS) 5 Oct 2021

16

Item

Cause

Diagnostic

Remedy

The pump

suction

pressure

gauge

indicates the

actual suction

pressure

The pump is

running empty

Water is not flowing into the pump

Open the pump inlet

valve and discharge

air

The pump is

running

backwards

The operating direction is incorrect

Correct the wiring

The number of

rotations is too

low

Measure the number of rotations

with a tachometer

Correct the frequency

The lifting height

is lower

See the instruction manual for the

pump

Replace with a new

pump

Foreign matter is

clogging the

pump

Check if there is foreign matter in

the pump inlet

Clean the pump

The pressure

gauge on the

pump outlet is

broken

The pressure gauges on the pump

inlet and outlet show the same

pressure at shutdown

Replace with a new

pressure gauge

Steam or

desuperheating

water are not

supplied

The steam inlet

valve is still

closed

The inlet valve is closed

Open the inlet valve

The steam

pressure control

valve (CV) is still

closed; the

steam pressure

control valve

does not move

at all

Check the wiring to the control

valve; check the controller wire

connections; check the input signal

wiring for incorrect connections

Check the electrical

wiring diagram and

correct the wiring

Check that a signal of 4 –20 mA is

being received by the CV at the

connection terminals

Adjust the controller or

positioner or replace

with a new controller

or positioner

Check the secondary pressure of

the steam pressure control valve; if

the electrical wiring and signal are

normal, then the steam pressure

control valve is malfunctioning

Disassemble, inspect

or replace the steam

pressure control valve

Check if air is being supplied to the

steam pressure control valve (CV)

positioner

Supply air to the

positioner

Does not reach

desired steam

pressure

The PID set

values are

incorrect

Check the PID set values

Correct the PID set

values

The pressure

sensor is

malfunctioning

Check the pressure value reading

from the sensor and compare with

the pressure gauge, if the electrical

wiring and signal are normal, then

the pressure sensor is

malfunctioning

Replace with a new

pressure sensor

Component(s)

inside the

pressure control

valve positioner

are broken

Check for abnormal sounds from

the positioner

Replace with a new

positioner

(Investigate whether

the valve aperture

changes frequently or

the ambient

temperature is too

high)

Continued on the next page

172-65608MA-03 (RGDS) 5 Oct 2021

17

Item

Cause

Diagnostic

Remedy

Does not reach

desired steam

pressure

There is a

problem with the

input current of

the pressure

control valve

Check that a signal of 4 –20 mA is

being received from the pressure

sensor at the connection terminals

Adjust the controller or

replace with a new

controller

Supply steam

pressure is too

low

Check whether there is a correct

steam pressure

Supply steam at the

correct pressure

Temperature

does not go

down

Operation at a

temperature

outside the

operating

specifications

Check the specifications

Operate within the

range of the operating

specifications

There is

insufficient

desuperheating

water

The Y-strainer installed on the

desuperheating water line is

blocked

Clean the Y-strainer

The lifting height of the pump has

decreased

If the pump lifting

height has decreased,

replace with a new

pump

Check the aperture of the

temperature control valve

(Check whether the value on the

controller and the valve aperture

match)

Correct the air

pressure supplied to

the positioner

Repair any air

leakages between the

temperature control

valve actuator and

positioner

The PID set

values are

incorrect

Check the PID set values

Correct the PID set

values

The temperature

sensor is

malfunctioning

Check the temperature value

reading from the sensor and

compare with the temperature

gauge, if the electrical wiring and

signal are normal, then the

temperature sensor is

malfunctioning

Replace with a new

temperature sensor

Temperature is

below the set

value

The temperature

sensor is

malfunctioning

Check the temperature value

reading from the sensor and

compare with the temperature

gauge, if the electrical wiring and

signal are normal, then the

temperature sensor is

malfunctioning

Replace with a new

temperature sensor

The condensate

separator is

blocked

Condensate is not being

discharged, the surface

temperature of the separator is cold

Perform maintenance

on the separator or

replace with a new

separator

The temperature

sensor is

installed wrong

The probe section of the

temperature sensor is not in the

center of the piping

(The sensor is measuring the

temperature of the condensate on

the bottom of the piping)

Correct the installed

length of the

temperature sensor

Continued on the next page

172-65608MA-03 (RGDS) 5 Oct 2021

18

Item

Cause

Diagnostic

Remedy

Does not reach

desired steam

temperature

The PID set

values are

incorrect

Check the PID set values

Correct the PID set

values

The temperature

sensor is

malfunctioning

Check the temperature value

reading from the sensor and

compare with the temperature

gauge, if the electrical wiring and

signal are normal, then the

temperature sensor is

malfunctioning

Replace with a new

temperature sensor

Component(s)

inside the

pressure control

valve positioner

are broken

Check for abnormal sounds from

the positioner

Replace with a new

positioner

(Investigate whether

the valve aperture

changes frequently or

the ambient

temperature is too

high)

There is a

problem with the

input current of

the temperature

control valve

Check that a signal of 4 –20 mA is

being received by the CV at the

connection terminals

Adjust the controller or

replace with a new

controller

Desuperheating

water pressure

is too low

Check whether there is a correct

steam pressure

Supply steam at the

correct pressure

172-65608MA-03 (RGDS) 5 Oct 2021

19

TLV EXPRESS LIMITED WARRANTY

Subject to the limitations set forth below, TLV CO., LTD., a Japanese corporation

(“TLV”), warrants that products which are sold by it, TLV International Inc. (“TII”) or

one of its group companies excluding TLV Corporation (a corporation of the United

States of America), (hereinafter the “Products”) are designed and manufactured by

TLV, conform to the specifications published by TLV for the corresponding part

numbers (the “Specifications”) and are free from defective workmanship and

materials. The party from whom the Products were purchased shall be known

hereinafter as the “Seller”. With regard to products or components manufactured by

unrelated third parties (the “Components”), TLV provides no warranty other than the

warranty from the third party manufacturer(s), if any.

Exceptions to Warranty

This warranty does not cover defects or failures caused by:

1. improper shipping, installation, use, handling, etc., by persons other than TLV,

TII or TLV group company personnel, or service representatives authorized by

TLV; or

2. dirt, scale or rust, etc.; or

3. improper disassembly and reassembly, or inadequate inspection and

maintenance by persons other than TLV or TLV group company personnel, or

service representatives authorized by TLV; or

4. disasters or forces of nature or Acts of God; or

5. abuse, abnormal use, accidents or any other cause beyond the control of TLV,

TII or TLV group companies; or

6. improper storage, maintenance or repair; or

7. operation of the Products not in accordance with instructions issued with the

Products or with accepted industry practices; or

8. use for a purpose or in a manner for which the Products were not intended; or

9. use of the Products in a manner inconsistent with the Specifications; or

10. use of the Products with Hazardous Fluids (fluids other than steam, air, water,

nitrogen, carbon dioxide and inert gases (helium, neon, argon, krypton, xenon

and radon)); or

11. failure to follow the instructions contained in the TLV Instruction Manual for the

Product.

Duration of Warranty

This warranty is effective for a period of one (1) year after delivery of Products to the

first end user. Notwithstanding the foregoing, asserting a claim under this warranty

must be brought within three (3) years after the date of delivery to the initial buyer if

not sold initially to the first end user.

ANY IMPLIED WARRANTIES NOT NEGATED HEREBY WHICH MAY ARISE BY

OPERATION OF LAW, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE AND ANY EXPRESS WARRANTIES NOT

NEGATED HEREBY, ARE GIVEN SOLELY TO THE INITIAL BUYER AND ARE LIMITED IN

DURATION TO ONE (1) YEAR FROM THE DATE OF SHIPMENT BY THE SELLER.

Exclusive Remedy

THE EXCLUSIVE REMEDY UNDER THIS WARRANTY, UNDER ANY EXPRESS

WARRANTY OR UNDER ANY IMPLIED WARRANTIES NOT NEGATED HEREBY

(INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE), IS REPLACEMENT; PROVIDED: (a) THE CLAIMED DEFECT IS

Table of contents

Other TLV Industrial Equipment manuals