Page 4 of 39

1. INTRODUCTION AND SAFETY

1.1 General

WARNING

These Instructions must always be kept close to product's operating

with the product.

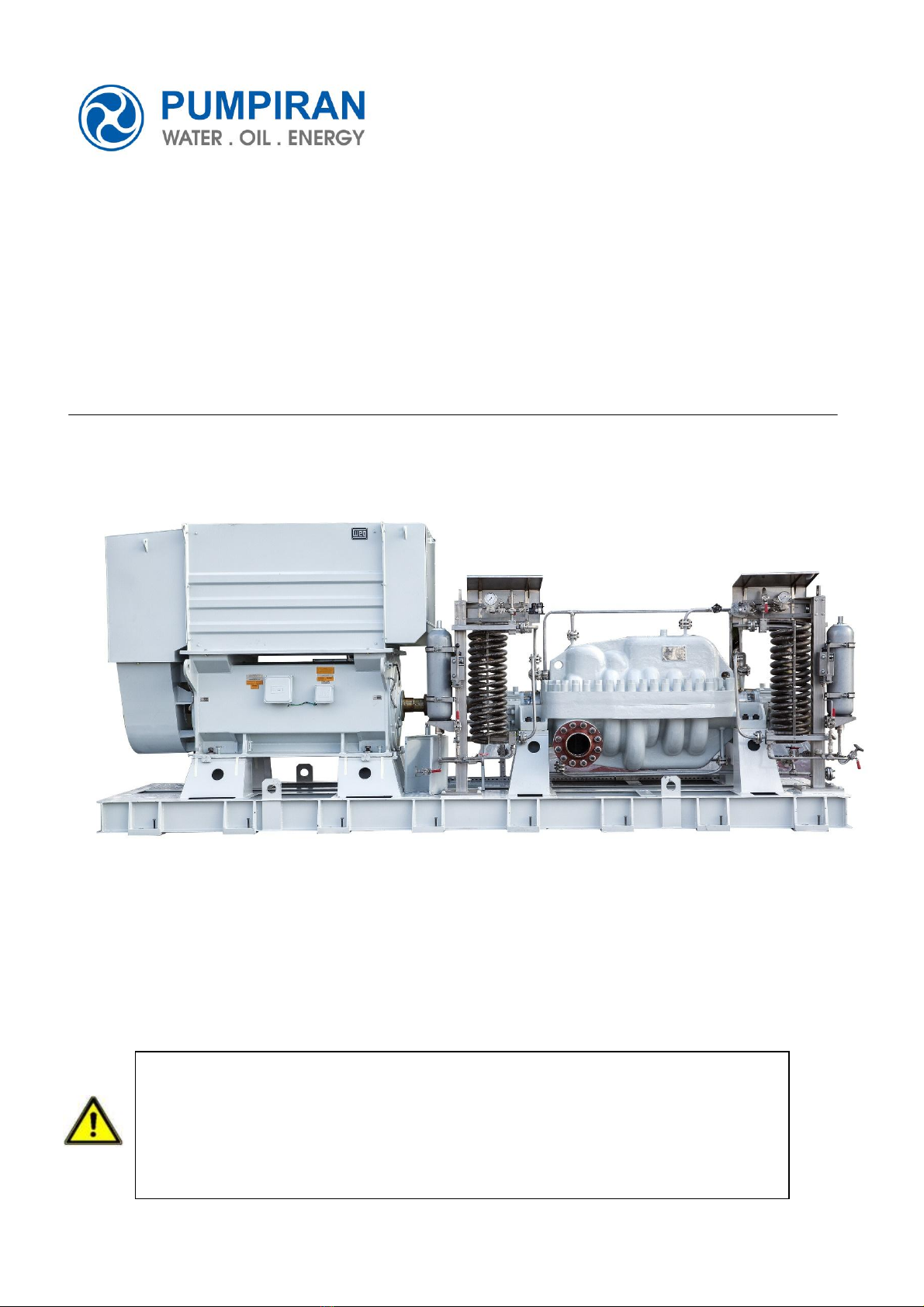

PUMPIRAN's products are designed, developed and manufactured with state-of-the-art technologies in modern

facilities. The unit is produced with great care and commitment to continuous quality control, utilizing

sophisticated quality techniques, and safety requirements.

PUMPIRAN is committed to continuous quality improvement and being at service for any further information

about the product in its installation and operation or about its support products, repair and diagnostic services.

WARNING

These instructions are intended to facilitate familiarization with the product and its

permitted use. Operating the product in compliance with these instructions is important to

help ensure reliability in service and avoid risks.

These instructions must be read prior to installing, operating, using and maintaining the

equipment. The equipment must not be put into service until all the conditions relating to

safety, noted in the instructions, have been met.

1.2 CE marking and approvals

Where applicable, the Directives and any additional Approvals, cover important safety aspects relating to

machinery and equipment and the satisfactory provision of technical documents and safety instructions. Where

applicable this document incorporates information relevant to these Directives and Approvals.

1.3 Disclaimer

Information in these User Instructions is believed to be reliable. In spite of all the efforts of PUMPIRAN

to provide sound and all necessary information the content of this manual may appear insufficient and is

not guaranteed by PUMPIRAN as to its completeness or accuracy.

PUMPIRAN manufactures products to exacting International Quality Management System Standards as

certified and audited by external Quality Assurance organizations. The failure to properly select, install or use

authorized PUMPIRAN parts and accessories is considered to be misuse. Damage or failure caused by misuse is

not covered by PUMPIRAN's warranty.

1.4 Duty conditions

This product has been selected to meet the specifications of your purchase order. The acknowledgement of these

conditions has been sent separately to the Purchaser.

WARNING

The product must not be operated beyond the parameters specified for the

application. If there is any doubt as to the suitability of the product for the

application intended, contact PUMPIRAN for advice, quoting the serial number.