1903-a00 4

S E C T I O N 1

Cautions—Read First!

CAUTION: Only personnel who are familiar with the

operation and repair of mechanical products should perform

the necessary maintenance. You must familiarize yourself

with the entire contents of this manual prior to operating

and/or performing any maintenance.

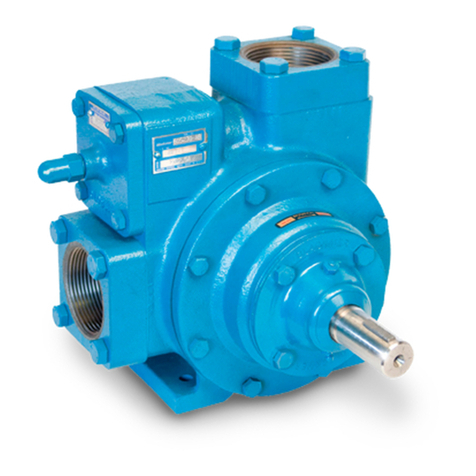

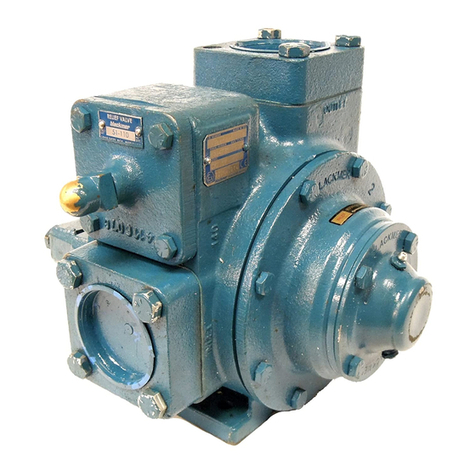

CAUTION: When selecting a V Series pump for an

application, you must first ensure that the pump components

are compatible with the process media.

CAUTION: Prior to startup, review and understand end-

clearance adjustments. Following these guidelines will

ensure proper end-clearance adjustment avoiding

interference between the gears and head. Interference may

cause heat generation and premature wear.

CAUTION: Do not operate this pump in excess of its rated

capacity, pressure, speed and temperature.

CAUTION: Before any maintenance and repair is

attempted, disconnect the drive.

CAUTION: Before any maintenance or repair is attempted,

bleed all pressure from the pump through the suction or

discharge lines.

CAUTION: Do not remove any pressure-containing

components during pump operation.

CAUTION: All V Series pumps contain residual hydraulic oil

from the factory production test. Hypar-FG 15 food-grade oil

is the standard production test fluid, but any certified

performance testing may be done on a non-food grade oil,

such as Unilube 32 (ISO 32) or Unilube 100 (ISO 100).

Determine if this is compatible with the fluid you are

pumping. If the fluid is incompatible, then the pump must be

fully flushed prior to use.

CAUTION: When pumping fluids at elevated temperatures,

care should be taken to gradually increase temperature.

Rapid temperature increase can damage internal

components.

CAUTION: Ensure that the pump has cooled to a safe

temperature before any maintenance or repair is attemped.

CAUTION: When pumping fluids at elevated temperatures

the piping may expand, resulting in excessive stress on the

pump. This can cause pump failure. Care must be taken

when considering pipe design to avoid damage from thermal

expansion.

CAUTION: Do not run the pump dry. This can cause

damage to internal components and generate heat, creating

a hazardous condition for volatile fluids.

CAUTION: Prevention of static sparking –If static sparking

occurs, fire or explosion could result. Pump, valves and

containers must be grounded to a proper grounding point

when handling flammable fluids and whenever discharge of

static electricity is a hazard.

CAUTION: The packing in a packed pump is designed to

leak. Therefore, when pumping hazardous liquids, a

mechanical seal is recommended to minimize any potential

source of leakage that could result in a hazardous condition.

CAUTION: Do not adjust packing while pump is in operation.

CAUTION: All inlet and discharge plumbing should be clean

and free from foreign material prior to startup of pump.

CAUTION: Keep hands and fingers away from any pump

opening while the pump is connected to the drive.

CAUTION: When connecting to an electric motor, follow all

safety recommendations provided by the motor

manufacturer.

WARNING: In any positive-displacement pump system, a

reliable pressure-protection device must be used in the

discharge piping to avoid a dangerous pressure increase,

which could cause the pump or any component in the

discharge piping to burst and can lead to serious injury. A

pump-mounted integral relief valve is not intended to be

used in this manner.

CAUTION: Never remove safety guards from shafts,

couplings, V-belts or pulleys during operation. Doing so

could result in injury.

CAUTION: When pumping high-temperature fluids, avoid

contact with the pump. Serious injury could occur.

CAUTION: Do not wear loose or dangling clothing or jewelry

near the equipment. These items could become caught in

the equipment and cause injury.

CAUTION: Before any maintenance or repair is attemped,

ensure that the pump has been thoroughly flushed of any

hazardous fluids. Review the Material Safety Data Sheet

(MSDS) applicable to the fluid for proper handling.