OWNER’S MANUAL -9- PNR-YF-05Y-A1

down position, no basic value current).

9. Press torch switch and electromagnetic valve starts, you will hear the sound of electricity-releasing HF sparkle

and at the same time, argon comes out from the torch.

10. Keep 2-4mm space between tungsten pole and working plate, and press torch control switch, then between

electrode and work piece HF electricity is released; After arc initiation, HF sparkle disappears soon and

can start to work.

11. When welding finished, adjust the post-flow knob to suitable place in order to protect welding surface.

12. When TIG welding, choose the 2T/4T switch for long welding and spot welding; when 2T, arc initiation and

down slope adjusting function do not work, only welding current works.

13. When 4T, pressing the torch switch is arc initiation current, while releasing the switch is welding current;

pressing again is down slope time adjusting, releasing again off working.

14. When repeat, arc initiation and down slope current are the same, and arc putting out is off working.

B. AC TIG WELDING

1. Operating as the1-4 step above. When put the switch to “AC” position, it is AC arc welding which is for

aluminum materials.

2. Pulse duty knob: During AC arc welding, current transfers between up side and down side continuously.

When current goes from tungsten stick to work piece, it is positive current time. At this moment, stick

heats slightly and quantity of heat is concentrated, which is good for welding. When current goes from

work piece to stick, it is down side current. At this moment, it can clean oxide at the surface of work force,

which improves welding result. But the stick may be burnt out because of over heat; the knob is for

adjusting time ratio of positive and reversed current.

3. Operating as the10-12 step above.

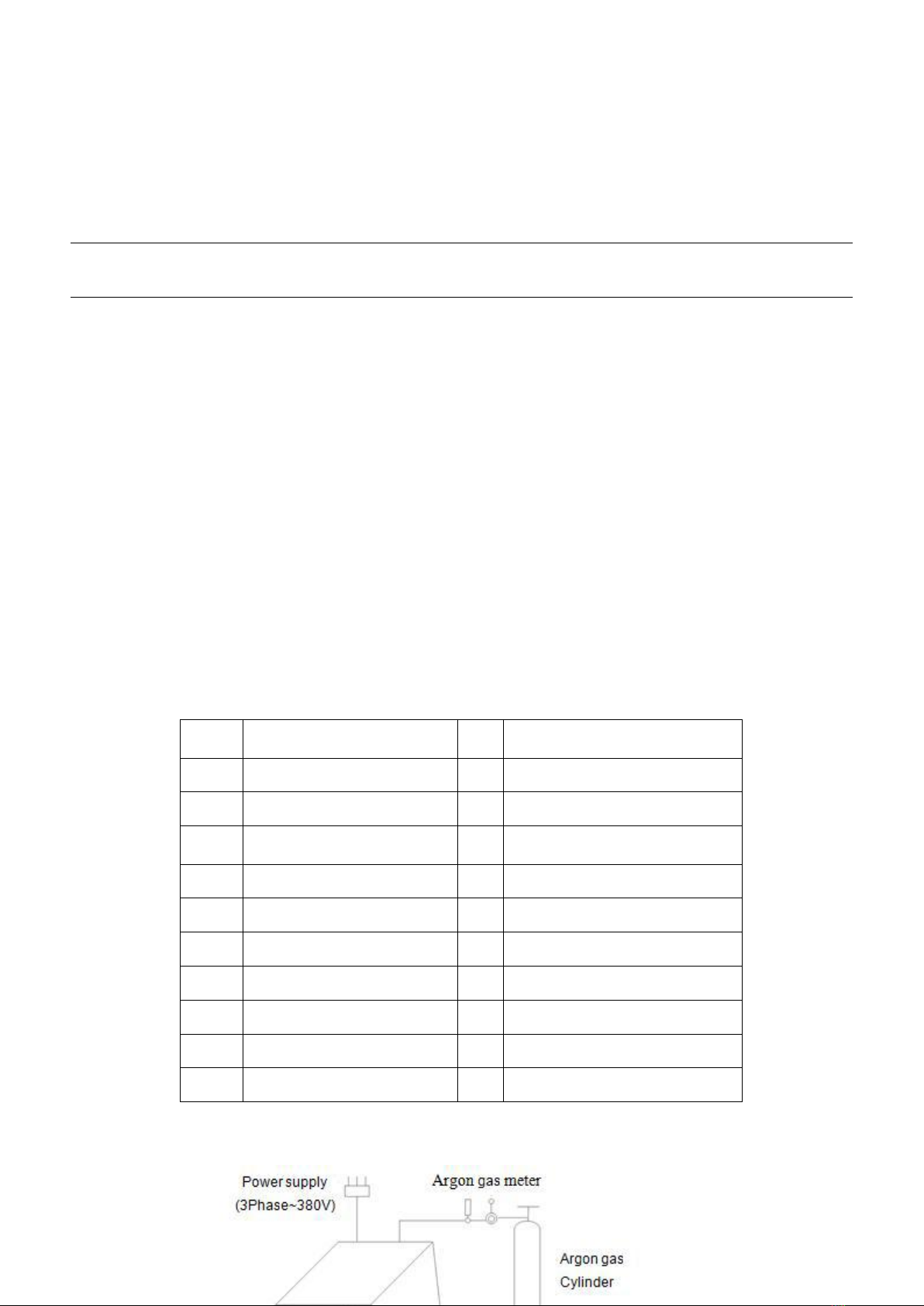

Attached:The Maximum permissible current for different power and tungsten stick

tungsten

stick diameter

(mm)

thorium-tungsten

Cerium-tungsten

thorium-tungsten

Cerium-tungsten