Smart Welder-MMA Series

INSTALLATION INSTRUCTION

If the connecting cable is too long, it will have a great influence on the arcing performance as well as the stability of the welding performance.

Therefore,please use the recommended length.If you want to reduce the voltage drop, please use a cable with a larger cross section.

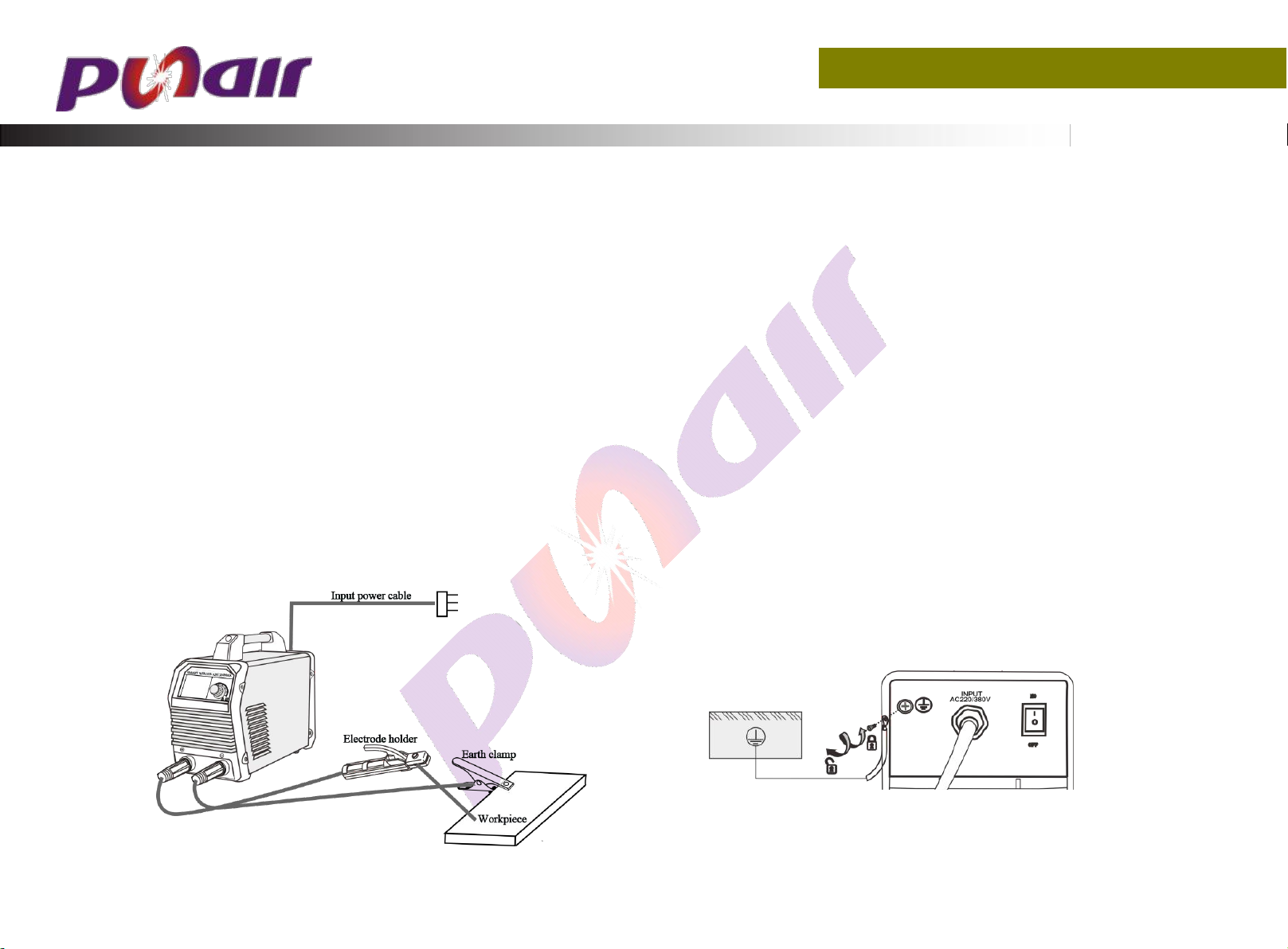

1) Ground the cables with section area no less than 6mm2to the housing,the way is connecting screw in the back of the power source to ground device;

2) Connect the power cable to the distribution box with the corresponding voltage level of the welder . Do not connect the wrong voltage and ensure that

the fluctuation of the input voltage is within the allowable range;

3) Make sure that the input power cable, output electrode holder, and output earth clamp are reliably connected. For the output interface, refer to the

connection method below and tighten it clockwise;

4) Please pay attention to the connecting terminal, DC welding machine has two connecting ways:

positive connection and negative connection. Positive connection: connect the electrode holder with “-” terminal,while workpiece with the “+” terminal.

Negative connection: workpiece with the“-” terminal, holder with the “+” terminal. Choose suitable way according to the working situation. If unsuitable

choice is made,it will cause unstable arc, more spatters and conglutination. If such problems occur, please change the polarity of the fastening plug.