OM-926 Page 6

DN’approchezpas le tube du chalumeau et l’arc pilote lorsque la gâ-

chette est enfoncée.

DLe câble de masse doit être pincé correctement sur la pièce à cou-

per, métal contre métal (et non de telle sorte qu’il puisse se

détacher),ou sur la table de travail le plus près possible de la ligne

de coupage.

DIsoler la pince de masse quand pas mis à la pièce pour éviter le

contact avec tout objet métallique.

DÉCHARGES ÉLECTRIQUES poten-

tiellement mortelles.

Il y a DES CHARGES DC SIGNIFICATI-

VES dans le poste de soudage inver-

seur même APRÈS coupure du cou-

rant d’alimentation.

DMettre l’unité hors tension, mesurer la tension des condensateurs

d’entrée et s’assurer qu’elle est pratiquement nulle avant de tou-

cher à l’une quelconque des pièces. Mesurer cette tension confor-

mément aux directives énoncées à la section Entretien du manuel

de l’utilisateur ou du manuel technique avant de toucher à l’une

quelconquedes pièces.

Risque de blessure en cas

D’EXPLOSION DES PIÈCES.

DMise sous tension, toute pièce défectueuse des

sources d’alimentation de l’inverseur peut explo-

ser ou faire exploser d’autres pièces. Pour entre-

tenir les inverseurs, toujours porter un masque

protecteur et un vêtement à manches longues.

Le coupage plasma produit des étincelles et projections de

métal à très haute température. Lorsque la pièce refroidit

du laitier peut se former.

LES ÉTINCELLES VOLANTES ris

quent de provoquer des blessures.

DPortez une visière ou des lunettes de sécurité avec des écrans laté-

raux approuvées.

DPortez des vêtements de protection adéquats afin de protéger votre

peau.

DAyez recours à des protège−tympans ou à un serre−tête ignifuges afin

d’éviter que les étincelles n’entrent dans vos oreilles.

Les rayons d’arc provenant du procédé de coupage

produisent des rayons visibles et invisibles intenses

(ultraviolets et infrarouges) qui peuvent entraîner des brûlures aux yeux et à la

peau.

LES RAYONS D’ARC peuvent entra

ner des brûlures aux yeux et à la peau

DLorsque vous coupez ou regardez quelqu’un couper, portez un cas-

que de soudage approuvé muni de verres filtrants approprié. La

norme ANSI Z49.1 (reportez−vous aux Principales normes de sécuri-

té) suggère d’utiliser un filtre de teinte nd9 (nd8 étant le minimum)

pour tout travail de coupage faisant appel à un courant de moins de

300 A. On mentionne également dans la norme Z49.1 qu’un filtre plus

faible peut être utilisé lorsque l’arc est caché par la pièce à couper.

Comme cela est habituellement le cas pour les travaux de coupage à

faible courant, les teintes énumérées au tableau 1 sont fournies à titre

d’information pour l’opérateur.

DPorter des lunettes de sécurité à coques latérales sous votre casque

ou écran facial.

DAyez recours à des écrans protecteurs ou à des rideaux pour protéger

les autres contre les rayonnements, les étincelles et les éblouisse-

ments; prévenez toute personne sur les lieux de ne pas regarder l’arc.

DPortez des vêtements confectionnés avec des matières résistantes

et ignifuges (cuir, coton lourd ou laine) et des bottes de protection.

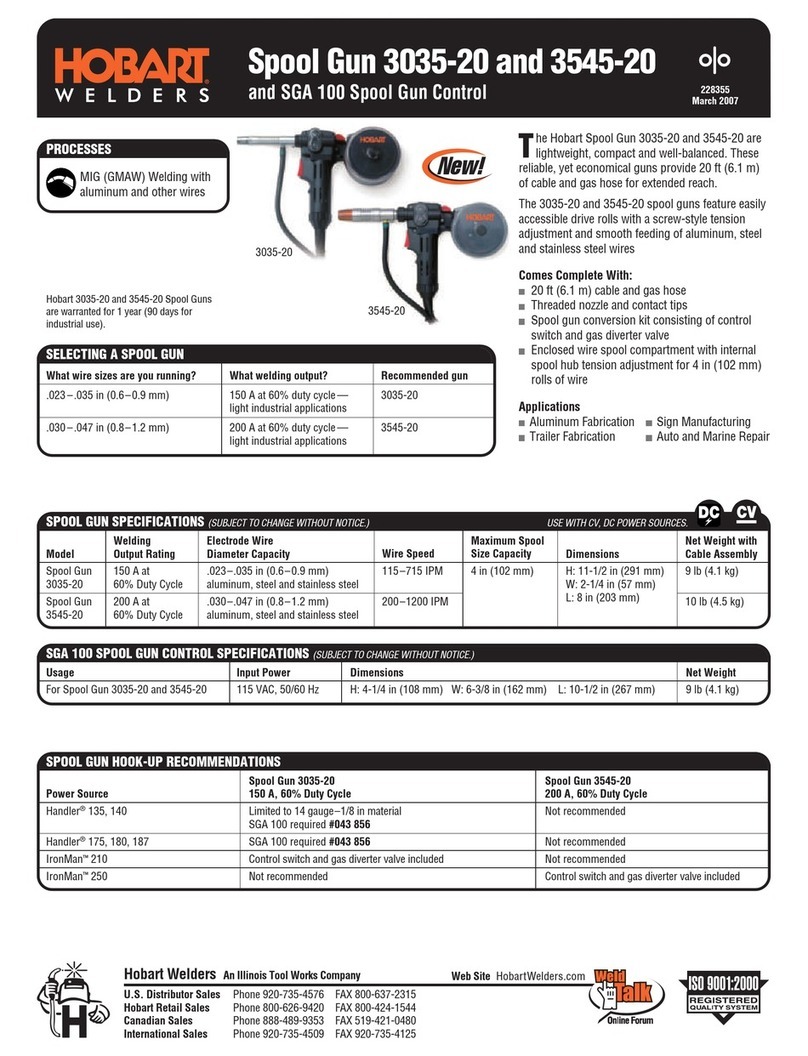

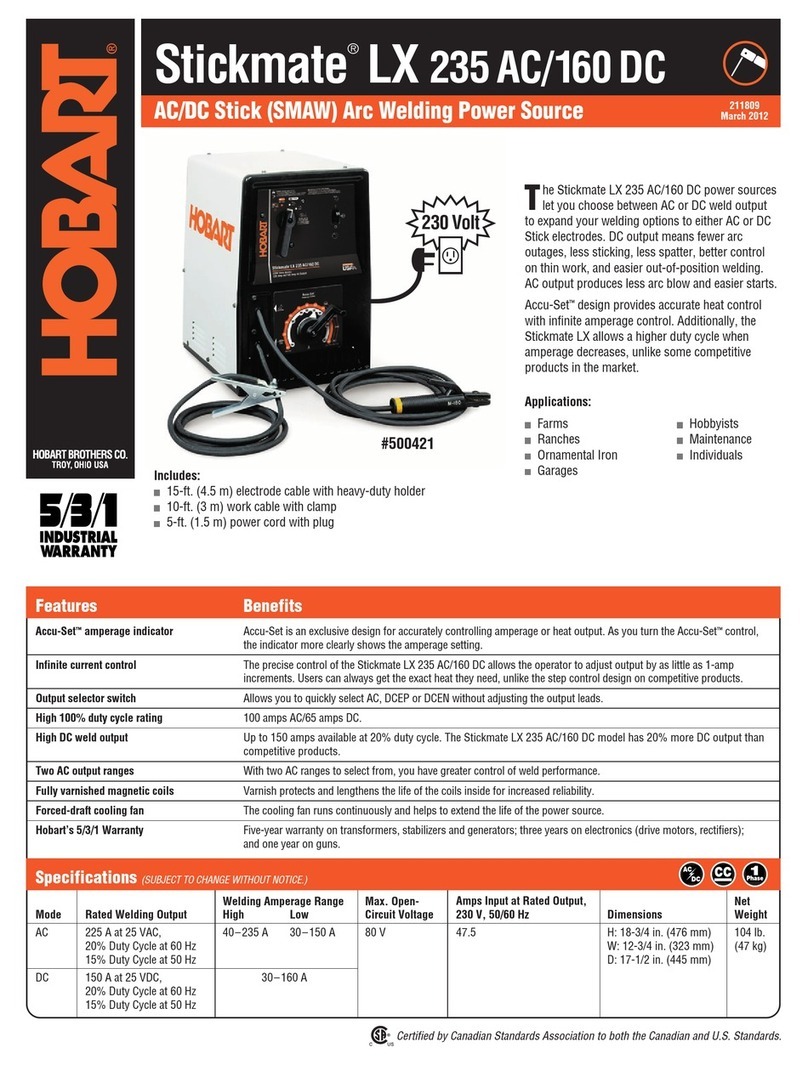

Tableau 1. Protection des yeux pour le coupage au plasma d’arc

Intensité de courant en ampères Filtre de teinte (minimum)

Moins de 20 no. 4

20 − 40 no. 5

40 − 60 no. 6

60 − 80 no. 8

Certaines applications de coupage produisent un bruit

constant, ce qui peut endommager l’ouïe si le niveau

sonore dépasse les limites permises par l’OSHA (repor-

tez−vous aux Principales normes de sécurité).

LE BRUIT peut endommager l’ouïe.

DUtilisez des protège−tympans ou un serre−tête antibruit si le niveau

sonore est élevé.

DPrévenez toute personne sur les lieux du danger relié au bruit.

LES FUMÉES ET LES GAZ peuvent

être dangereux.

Le coupage produit des vapeurs et des gaz. Respirer

ces vapeurs et ces gaz peut être dangereux pour la

santé.

DNe mettez pas votre tête au−dessus des vapeurs. Ne respirez pas ces

vapeurs.

DSi vous êtes à l’intérieur au moment du coupage, ventilez la pièce ou

ayez recours à une ventilation aspirante installée près de l’arc pour

évacuer les vapeurs et les gaz.

DSi la ventilation est médiocre, utilisez un respirateur anti−vapeurs

approuvé.

DLire et comprendre les spécifications de sécurité des matériaux

(MSDS) et les instructions du fabricant concernant les métaux, les

consommables, les revêtements, les nettoyants et les dégraisseurs.

DTravaillez dans un espace restreint uniquement s’il est bien ventilé ou

si vous portez un respirateur anti−vapeurs. Les vapeurs causées par

le coupage et l’épuisement de l’oxygène peuvent altérer la qualité de

l’air et entraîner des blessures ou la mort. Assurez−vous que l’air am-

biant est sain pour la santé.

DNe coupez pas dans un endroit près d’opérations de décapage, de

nettoyage ou de vaporisation. La chaleur et les rayons d’arc peuvent

réagir avec les vapeurs et former des gaz hautement toxiques et irri-

tants.

DNe coupez pas des métaux enrobés tels que des métaux galvanisés,

contenant du plomb ou de l’acier plaqué au cadmium, à moins que

l’enrobagene soit ôté de la surface du métal à couper, que l’endroit où

vous travaillez ne soit bien ventilé, ou que vous ne portiez un respira-

teur anti−vapeurs. Les enrobages ou tous métaux qui contiennent ces

éléments peuvent créer des vapeurs toxiques s’ils sont coupés.

DNe coupez pas de contenants qui renferment ou ont renfermés des

matières toxiques ou réactives − vous devez en premier lieu les vider

et les nettoyer convenablement.

LE PLASMA D’ARC peut entraîner

des blessures.

La chaleur dégagée par le plasma d’arc peut entraîner de

sérieuses brûlures. La force de l’arc est un facteur qui

s’ajoute au danger de brûlures. La chaleur intense et la

puissance de l’arc peuvent rapidement passer au travers

de gants et de tissus.

DN’approchez pas le tube du chalumeau.

DNe saisissez pas la pièce à couper près de la ligne de coupage.

DL’arc pilote peut causer des brûlures − n’approchez pas le tube du cha-

lumeau lorsque vous avez appuyé sur le gâchette.

DPortez des vêtements de protection adéquats qui recouvrent tout vo-

tre corps.

DNe pointez pas le chalumeau en direction de votre corps ni de la pièce

à couper lorsque vous appuyez sur la gâchette − l’arc pilote s’allume

automatiquement.

DMettez l’alimentation hors tension et débranchez le cordon d’alimen-

tation avant de démonter le chalumeau ou de changer une pièce du

chalumeau.

DUtilisez uniquement le ou les chalumeaux recommandés dans le ma-

nuel de l’opérateur.

Les bouteilles de gaz contiennent du gaz sous haute

pression. Si une bouteille est endommagée, elle peu

exploser. Puisque les bouteilles de gaz font habituellemen

partie d’un processus de travail des métaux, assurez−vous

de les manipuler correctement.

LES BOUTEILLES peuvent explose

si elles sont endommagées.

DProtégez les bouteilles de gaz comprimé contre la chaleur excessive,

les chocs mécaniques, des dommages physiques, le laitier, la flam-

me, les étincelles et l’arc.

DInstallez et attachez les bouteilles dans la position verticale à l’aide

d’une chaîne, sur un support stationnaire ou un châssis porte−bouteil-

le afin de prévenir qu’elles ne tombent ou ne basculent.