19-00132_MTS8-24_Standard_Installation_Manual_082819_Rev4.docx Page 4 of 24

SEQUENCE ( I ) - Installation Steps Overview

Note: See Required Tools section (page 20)

1. Verify parts received.

2. Call Puradyn toll-free 1-866-787-2396 (in North America) or +1 561 547 9499, if any parts are

missing or damaged.

3. Read this installation manual to become familiar with the installation process.

4. Survey equipment or vehicle to determine the mounting location.

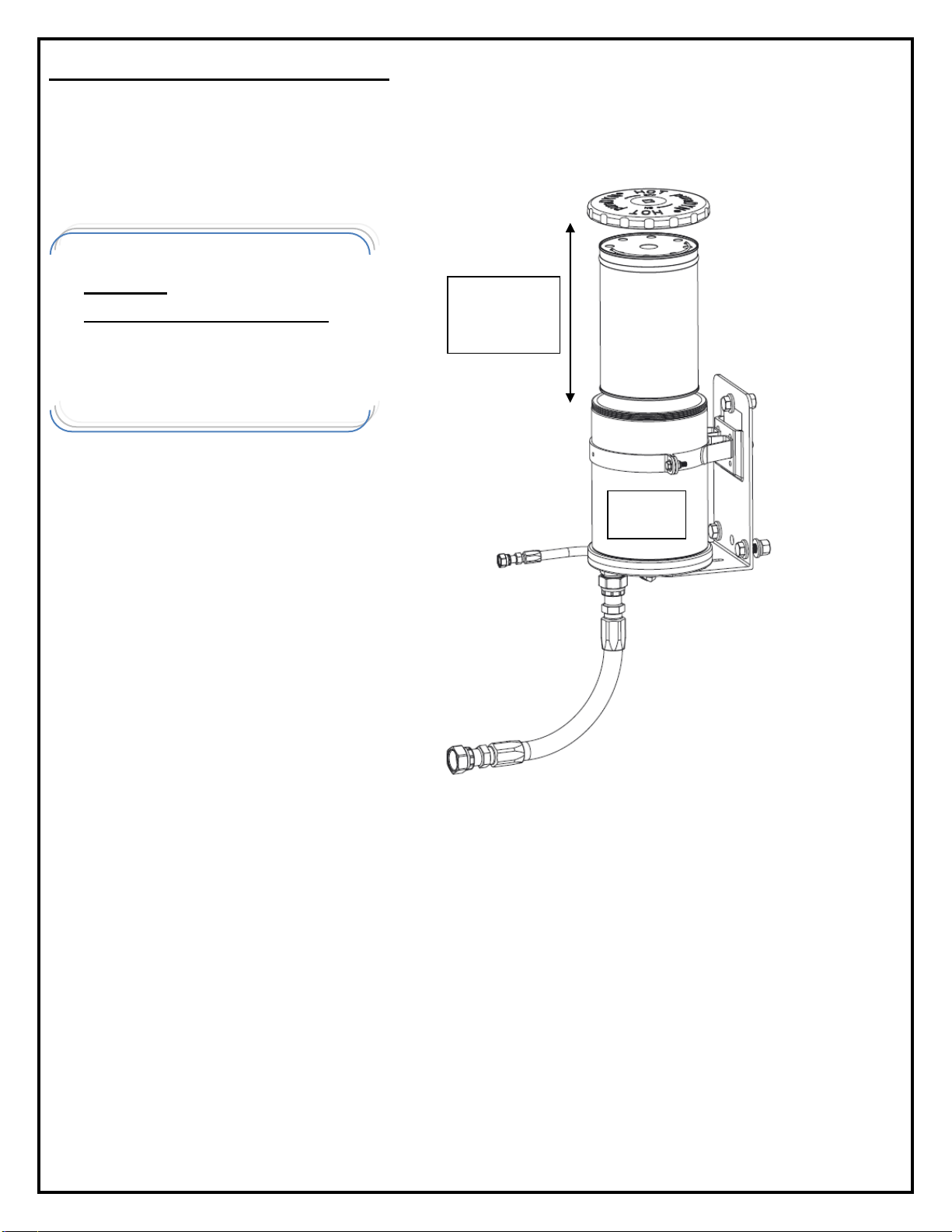

5. Verify adequate physical unit clearance, accessibility of oil sample valve & room for oil sample

bottle; also, check that there is enough clearance to change filter element.

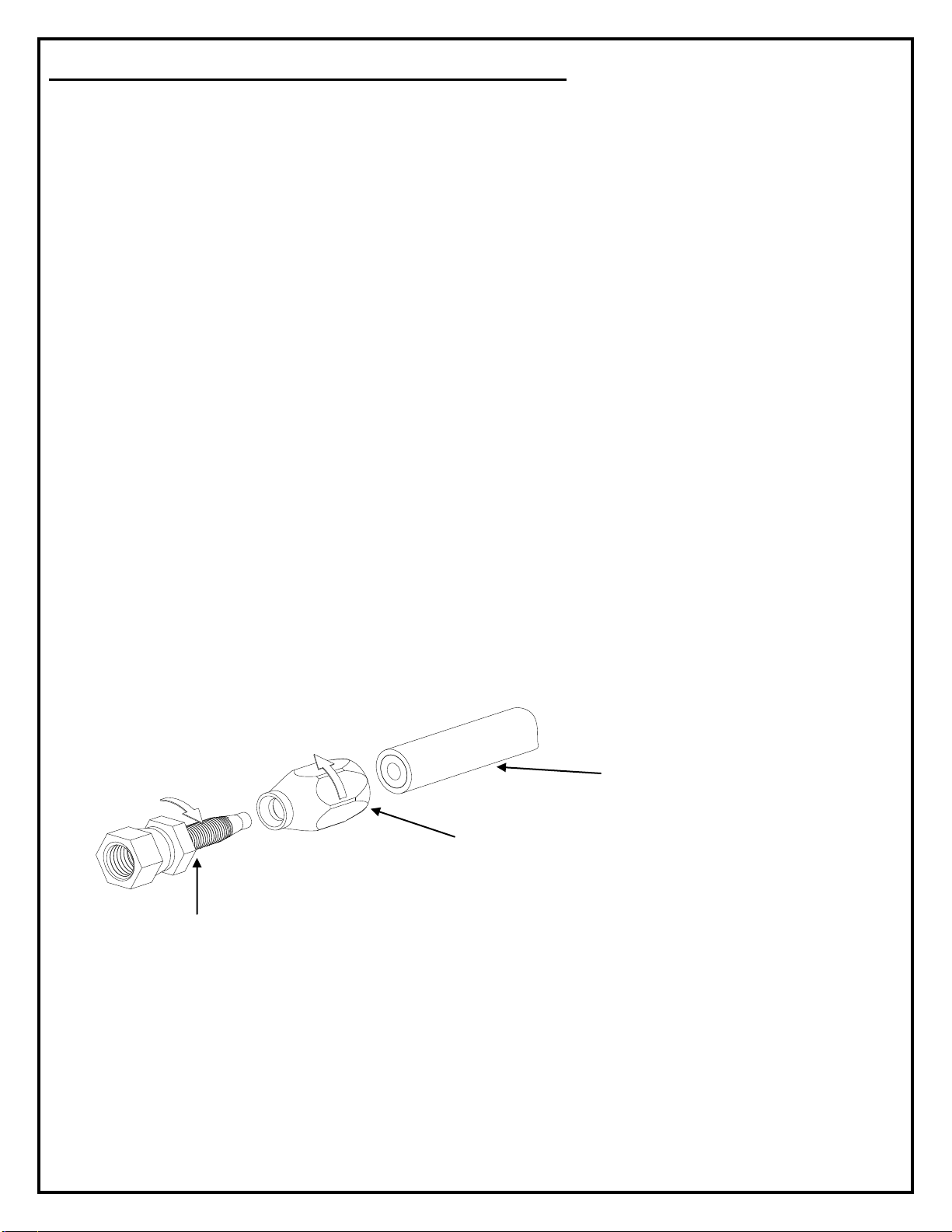

6. Inspect the new pre-assembled (Plug and Play) unit and other accessories.

7. Use a mounting-hole template to locate the mounting holes onto the designated location.

8. Drill out the holes; install the center hinge-pin bolt with about ½” slack.

9. Hang the pre-assembled system onto this center hinge-pin bolt. Tighten up slightly and position

other mounting holes to be lined-up with the L-bracket plate. Fastened all the mounting bolts

onto the firewall or structural frame-wall.

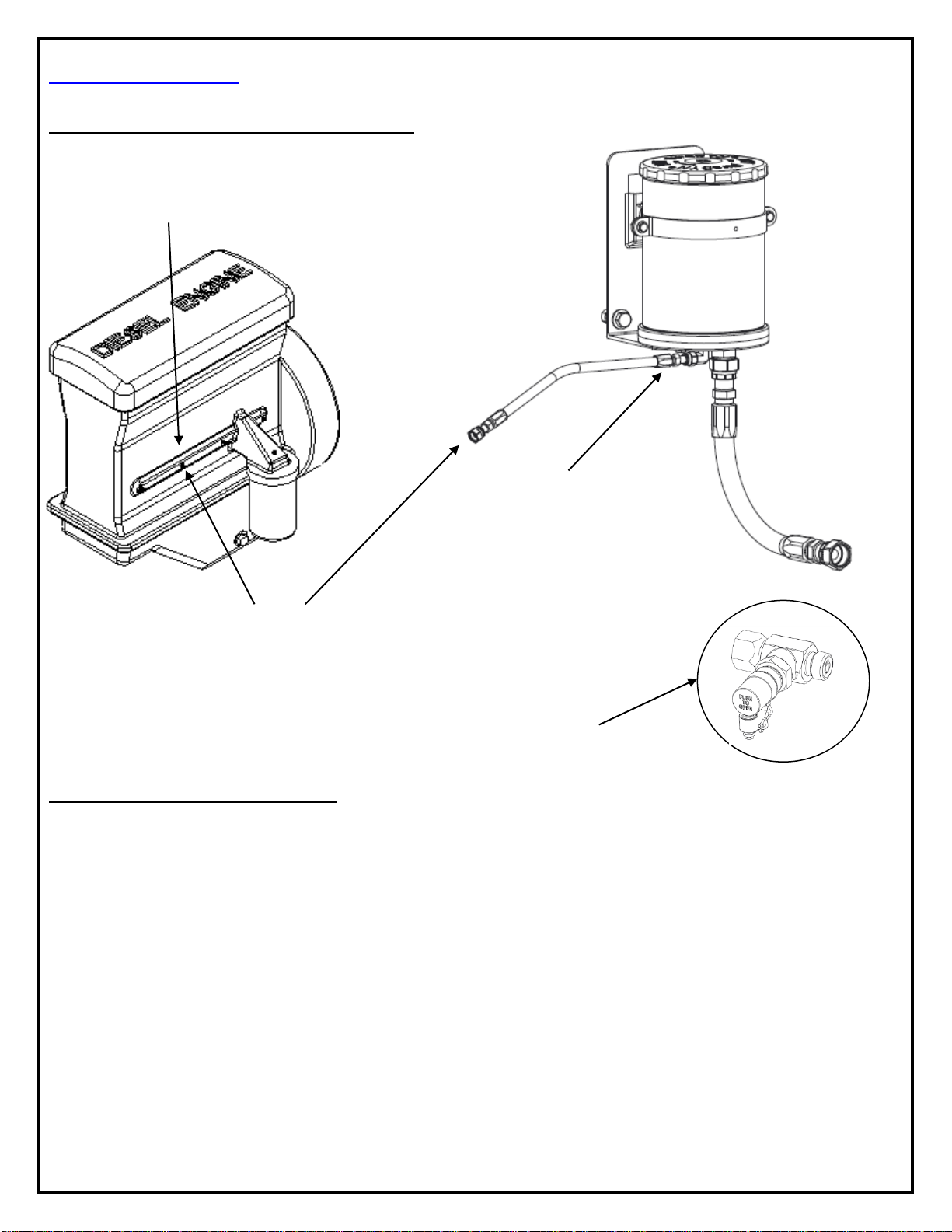

10. Attach oil supply line to puraDYN® System and engine or equipment’s supply port (ex. oil galley).

11. Attach oil return line to puraDYN® System.

12. Drain old oil completely from equipment, taking an oil sample of the drained oil to use as a

reference of the current engine and oil condition.

13. Install new OEM full flow filter per OEM instructions.

14. Connect other side of oil return line to engine or equipment’s (non-pressurized) sump.

15. Refill engine with new oil, taking another oil sample to establish a base line of the new oil that

will be used.

16. After system installation is completed, please go to System Start-Up section of this manual for a

step-by-step start-up/operation test.

Important Continuous Maintenance Reminders

Please review maintenance schedule for recommended filter change intervals –if you need help

generating your oil service interval schedule with puraDYN® System, please call Puradyn’s

technical support TEAM.

Use oil analysis to confirm oil is good for continued use.

Maintain a good preventive maintenance program on engine and equipment.

Routinely check oil level using engine dipstick.

Change oil according to oil analysis recommendation.

Please reference System Startup page for adding required quantity of (make-up) oil and note,

the added oil must be compatible with oil already in the system. Example. API–CJ-4 (API

category and brand may have differences in the additive package).