EN

6

room for installing softening

unit/antiscalant (option) and

possibly a reservoir tank (option).

You must expect 1000 mm extra

height in order to be able to take

out the plant membranes. Also

there shall be room at both sides

of the plant for water

installations, especially you must

consider the outlet drain from the

plant. A resistance must

never occur in those!

Furthermore, there are readings

which have to be made at the

front of the plant, e.g. the flow

meter, manometer, conductivity

meter and alarms.

The front of the plant shall never

be covered up, but must always

be visible.

In case of an error, situations

may arise where either the level

in the reservoir (Option) may

overflow or another form of leak

may occur. There shall always be

a floor drain close to the plant,

so that this water cannot cause

damage.

4. WATER QUALITY

The raw water, which is to be

treated in the BWT PERMAQ®

PRO 2500 plant, must be of

drinking water quality and

contain maximum 500 mg/l TDS.

The raw water may maximum

contain:

Hardness 0.5 dH (can

be obtained by means

of a softening

unit(option))

Fe: 0.05 mg/l

Mn: 0.05 mg/l

Free chlorine 0.1 mg/l

(if higher, install a

carbon filter (option))

Turbidity max. 1.0 NTU

Silt index: 3.0

KMnO4max.: 10 mg/l

Maximum temperature:25 C.

Note! The plant has been

adjusted in our factory to operate

at 10 C .

If you have doubts about the

composition of the raw water,

you should always make a water

analysis.

The plant must be connected to a

raw-water pressure of minimum 3

bar and maximum 6 bar. The

quality of the treated water will

normally be under 20 µS/cm at

10 C.

5. WATER

CONNECTIONS

Note! All water connections

must be in compliance with local

regulations.

For connection of raw water to

the softening unit (option), see the

guide which is enclosed the

softening unit.

Connection of softening to

the RO plant:

Connect soft water to the

connection at the left side of the

plant. The best operating result is

obtained by connecting to

minimum 1 ½" raw water pipe.

In that way you will usually

obtain the necessary pressure

and flow to the plant.

If the raw-water connection is too

small, there is the risk of outages

on the plant due to lacking water

pressure/amount, e.g. when

flushing membranes, when

starting up the plant and a poor

functionality of the softening unit.

Connection of permeate

outflow

The outflow of the RO plant (D)

shall be connected to hold-up

tanks or BWT reservoir (option).

You will benefit by connecting

with 1" flexible pressure hoses.

BWT sell complete assembly kits

for the BWT PERMAQ® PRO

2500- series.

Intake soft

water

Micron filter

(option)

Outflow

concentrate

discharge

Outlet

permeate to

consumption

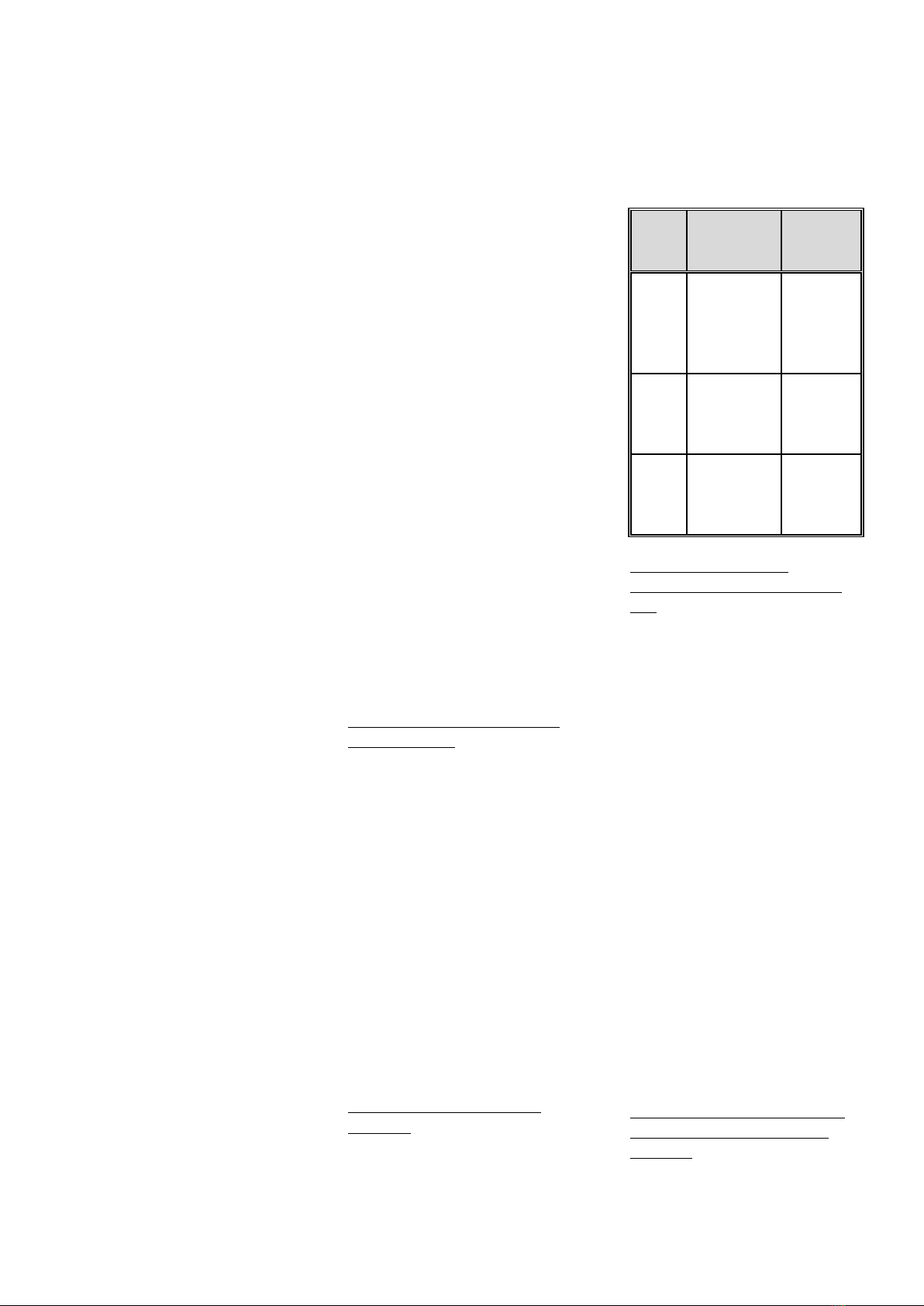

Connection of drain

(permeate (C)/concentrate

(B))

The permeate and concentrate

outlet can with advantage be

installed with two 25 mm PVC

pipes. Keep in mind that the

permeate drain must be made of

corrosion-proof material.

Permeate and concentrate

outflows are led to the floor drain

in two pipes. These two pipes

may never be united into one

pipe (see figure 1).

Important! The outlet pipe may

not be led all the way down into

the outlet water of the floor drain,

as you will then risk that the

water is sucked back into the

plant by standstill.

Important! A resistance may

never occur in the outlet pipe,

as this will damage the

membrane(s).

Connection of outlet water

from the reservoir pump

(option)

Connect the outlet water with 1"

flexible pressure hose to the