Bump Caps

General Specications

Standard: CE EN812:2012

Shell: acrylonitrile-butadiene-styrene (ABS)

Cap: polyester & cotton

Date code: indicated month and year when the shell was molded –

does not indicate service life

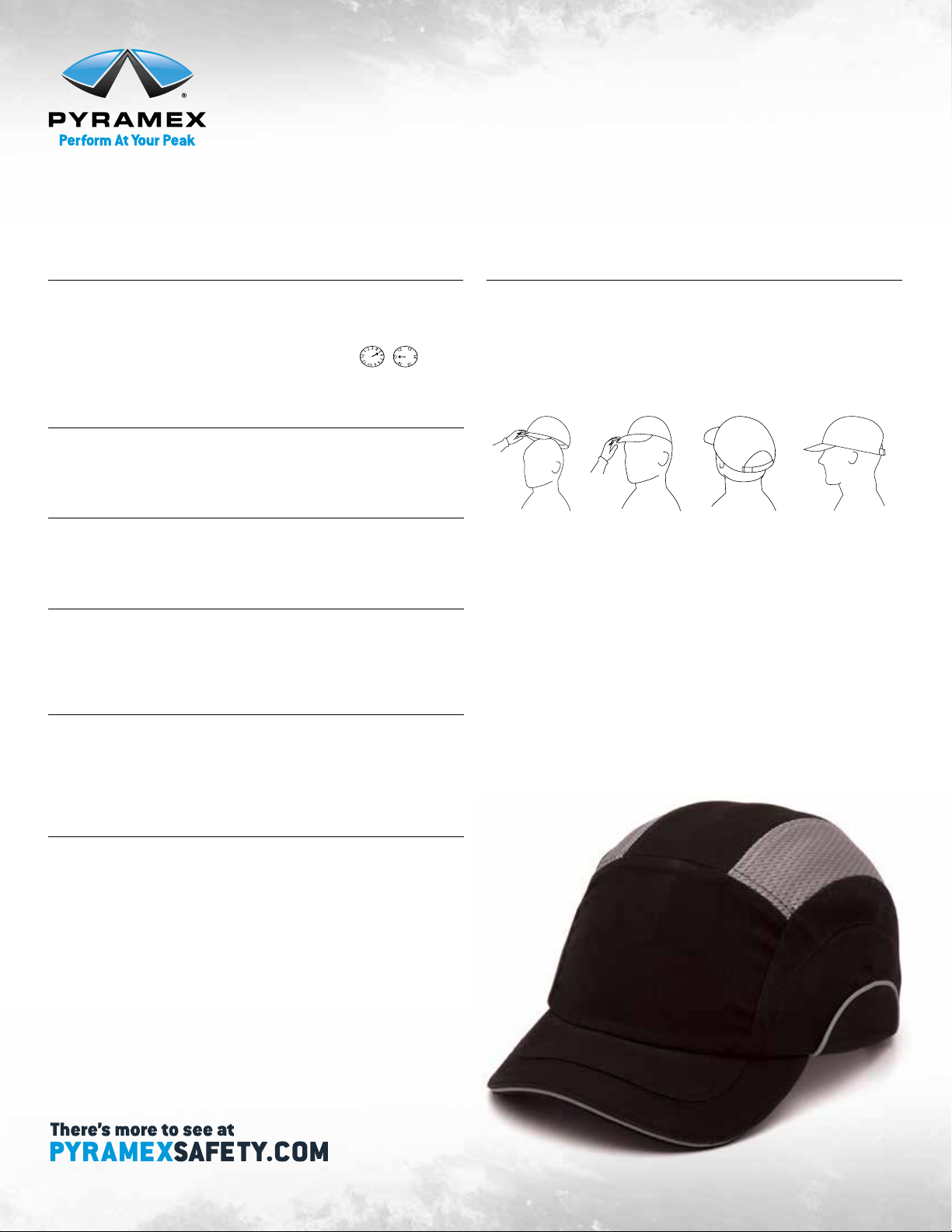

Wearing Instructions

1. Take the front shell of cotton cap, oblique the cap to make the rear be lower.

2. Wear the rear cap on behind of the head rstly and then set the front cap to forehead,

adjust the adjustment band suitable.

3. Adjustment band should be behind of head at outstanding point, as Figure 4

4. A correct position of rear band can set the cap tight and stable on head.

If the adjustment band is too tight, the cotton cap may move and provide

inadequate protection.

Figure 1 Figure 2 Figure 3 Figure 4

Requirements

This bump cap, working cap complies with the requirements of EN812:2012 industrial

bump cap and the European Directive 89/686/EEC

Storage

When not in use, it is recommended to store this bump cap, working cap in a clean and

dry environment and not placed in direct sunlight or in contact with solvents.

Direction of Use

This bump cap, working cap are designed for your personal safety. It must be worn during

the whole duration of exposure to any potential hazard. Leave the work area immediately

if the bump cap, working cap becomes damaged.

Duration of Use

Inspect for damage regularly. If the shell or harness, working cap show any signs of

damage it must be replaced immediately. The shelf life of this product, if stored and

used correctly, is indenite. However, we would recommend it be changed every 2-3

years as necessary.

Cleaning and Maintenance

To maintain your bump cap in optimum condition:

1. Do not use any abrasive materials or solvents

2. Clean any part of the bump cap working cap, with warm soapy water and dry with

a soft cloth. A mild disinfectant can also be used, in line with the manufacturers

instructions, if required.