8540571 - 25/08/2016 - Rev.15

PHOTOELECTRIC

SAFETY

BARRIER

VISION VX

INSTALLATION USE AND MAINTENANCE

INDICE

INTRODUCTION...................................................................................................................2

NEW SAFETY PARAMETERS FOR TYPE 2 BARRIERS AND MANDATORY LABELLING.......3

OPERATION .........................................................................................................................4

INSTALLATION.....................................................................................................................5

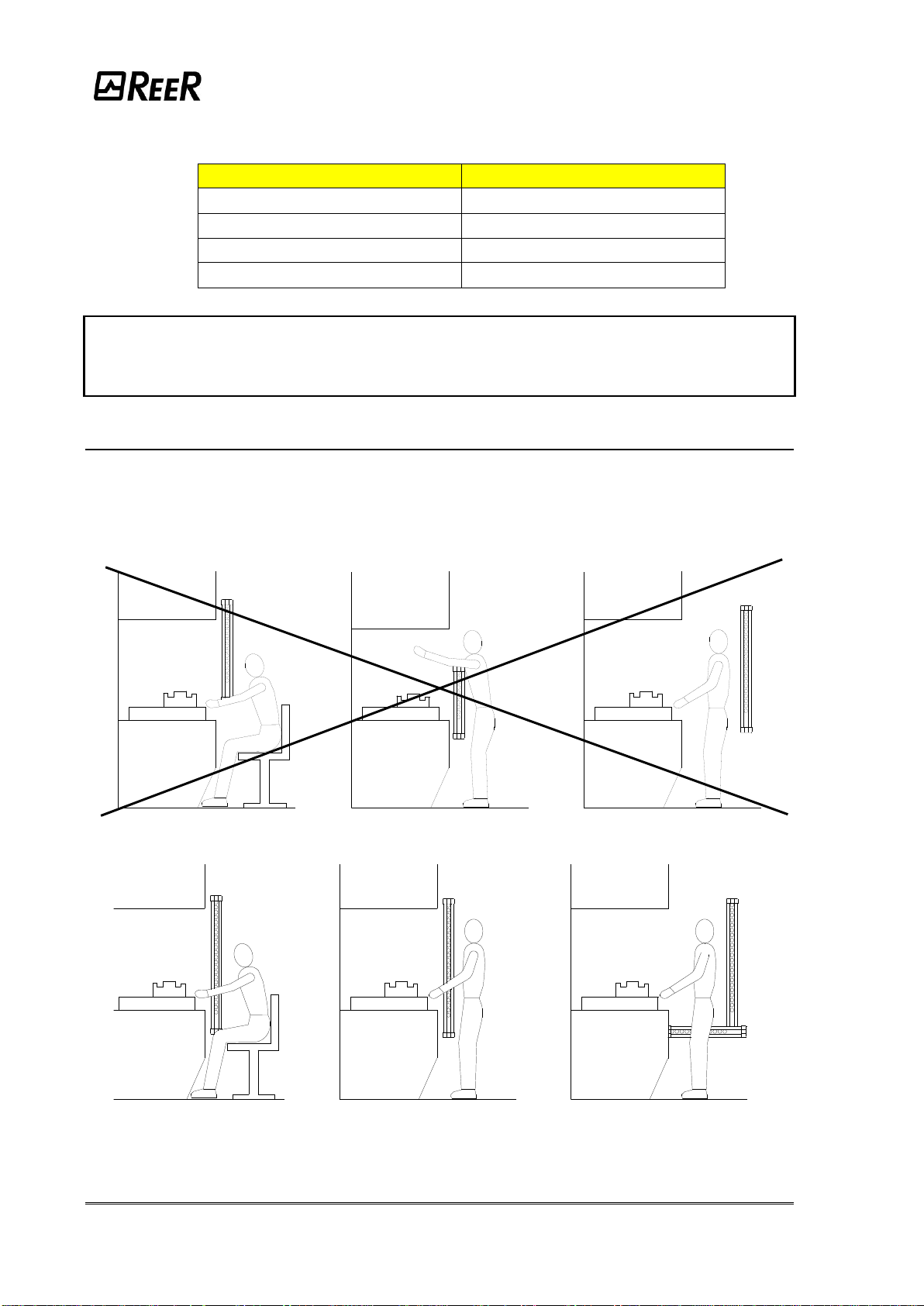

POSITION......................................................................................................................................6

MASTER/SLAVE POSITIONING...................................................................................................6

SAFETY DISTANCE CALCULATION............................................................................................8

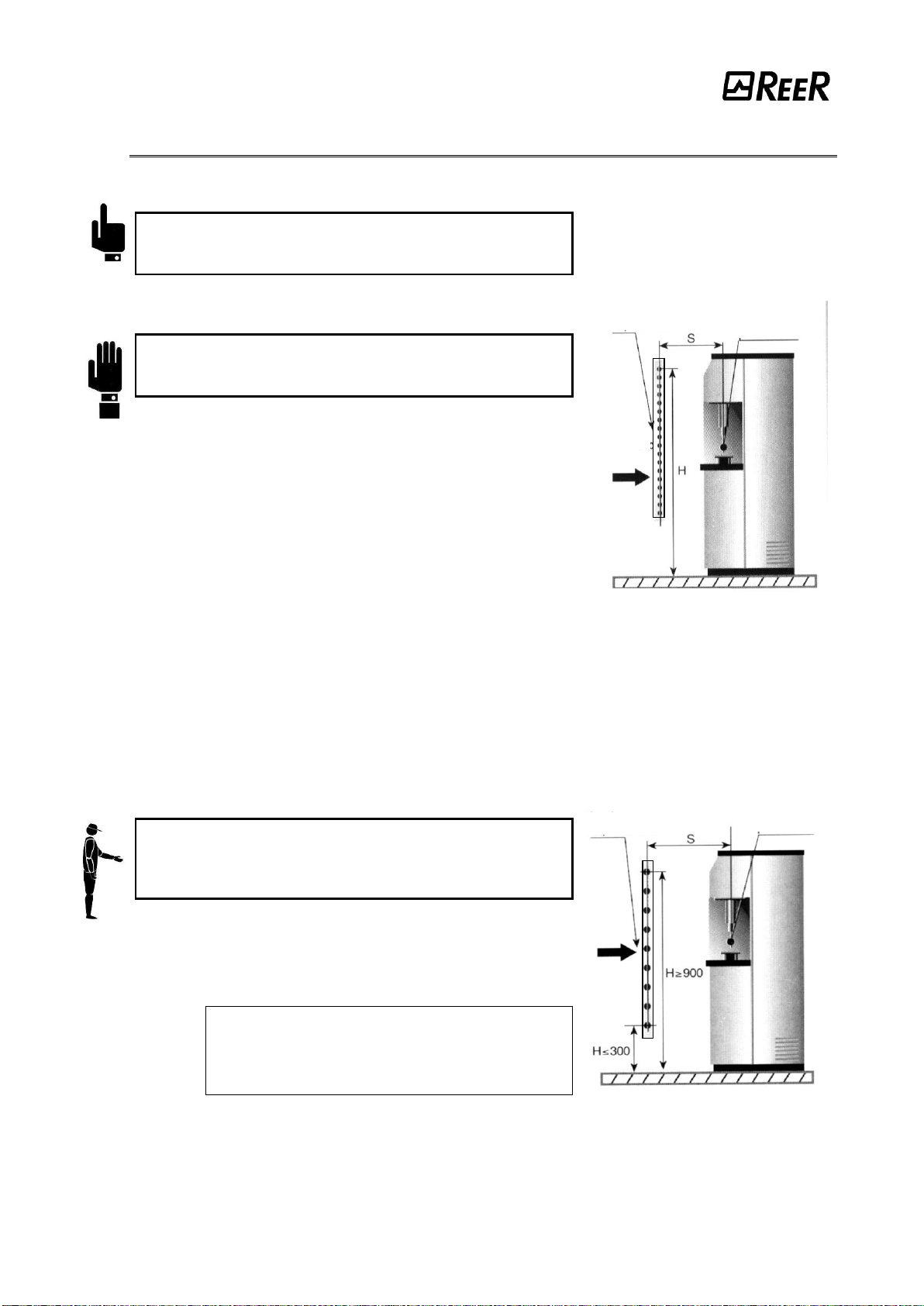

VERTICAL POSITION OF THE BARRIER....................................................................................9

HORIZONTAL POSITION OF THE BARRIER ........................................................................... 10

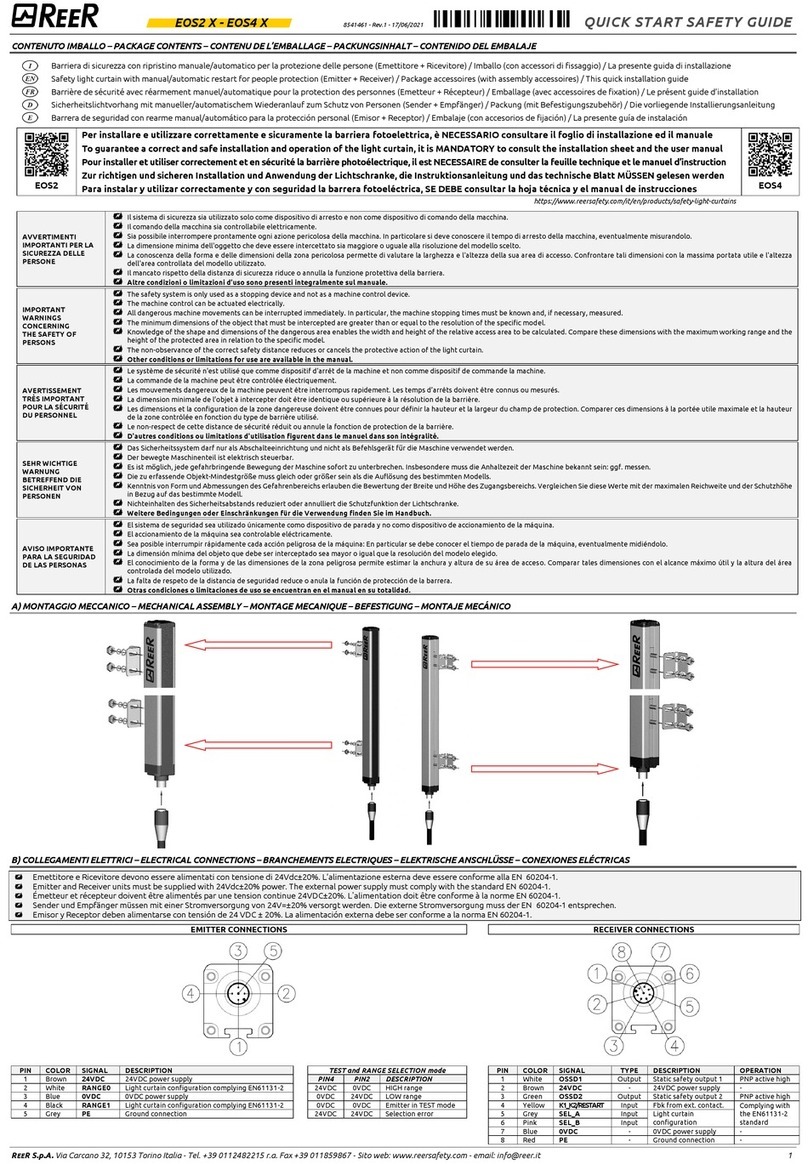

ELECTRICAL CONNECTIONS .................................................................................................. 11

EMITTER CONNECTIONS......................................................................................................... 12

RECEIVER CONNECTIONS...................................................................................................... 12

WARNINGS REGARDING THE CONNECTION CABLES......................................................... 13

CONFIGURATION AND OPERATION MODES......................................................................... 19

K1/K2 EXTERNAL CONTACTORS CONNECTION................................................................... 20

MULTIPLE SYSTEMS ................................................................................................................ 20

USE OF DEFLECTION MIRRORS............................................................................................. 21

DISTANCE BETWEEN REFLECTING SURFACES .................................................................. 22

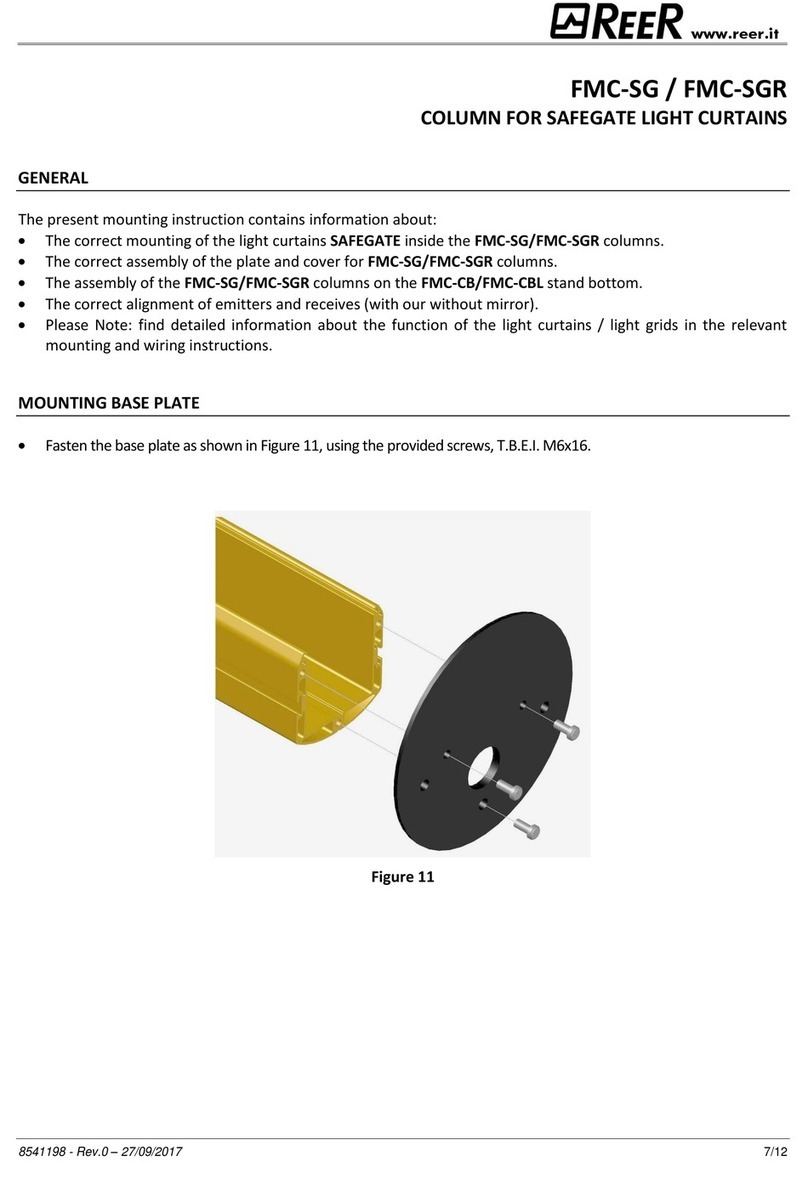

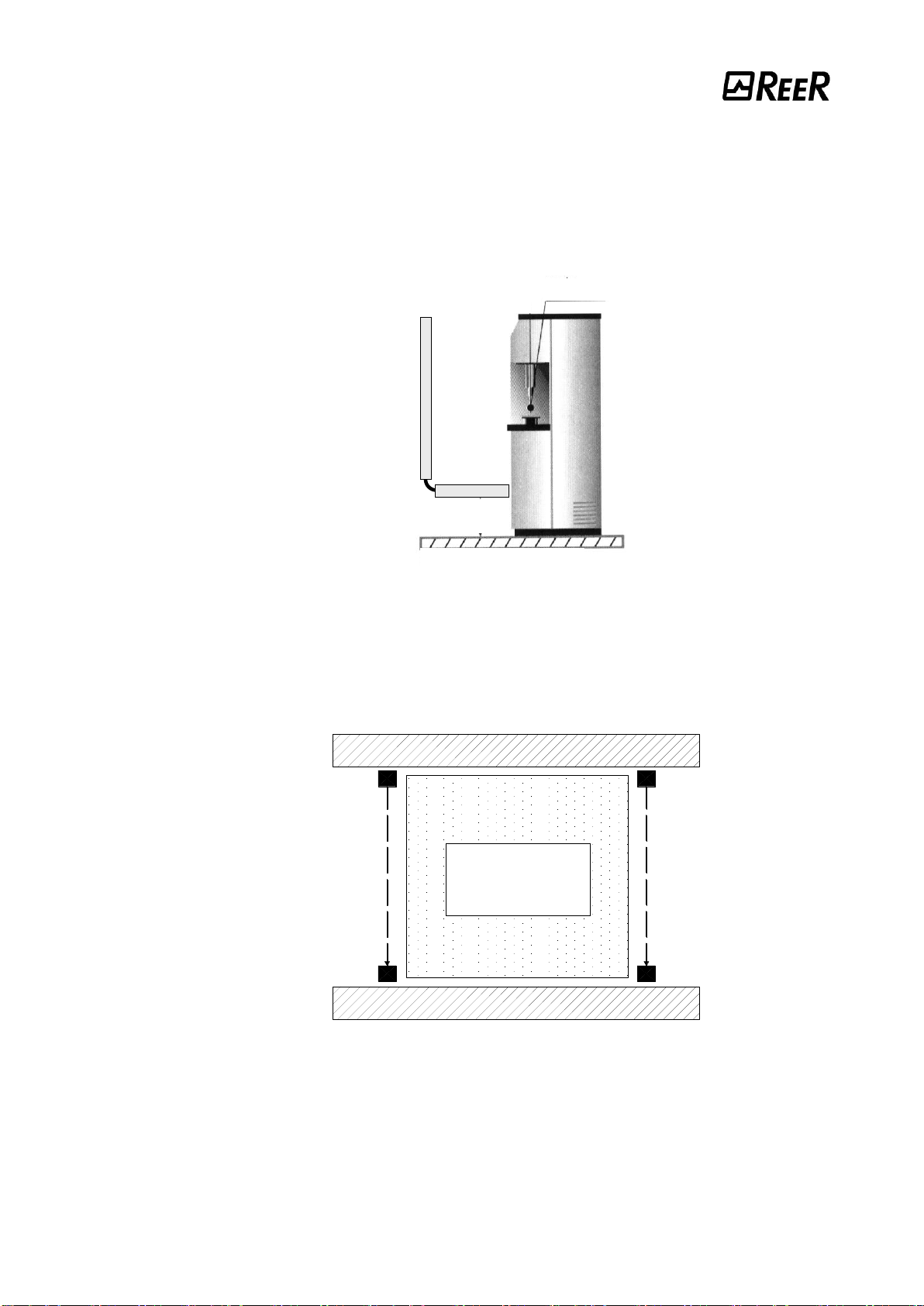

MECHANICAL ASSEMBLY AND OPTICAL ALIGNMENT......................................................... 23

OPERATION AND TECHNICAL DATA................................................................................24

SIGNALS..................................................................................................................................... 24

TEST FUNCTION ....................................................................................................................... 26

OUTPUT STATUS ...................................................................................................................... 27

TECHNICAL SPECIFICATIONS................................................................................................. 28

DIMENSIONS......................................................................................................................30

CHECKOUTS AND MAINTENANCE...................................................................................32

VERIFICATION OF BARRIER EFFICIENCY ............................................................................. 32

TROUBLESHOOTING................................................................................................................ 33

SPARE PARTS....................................................................................................................36

GUARANTEE ......................................................................................................................37