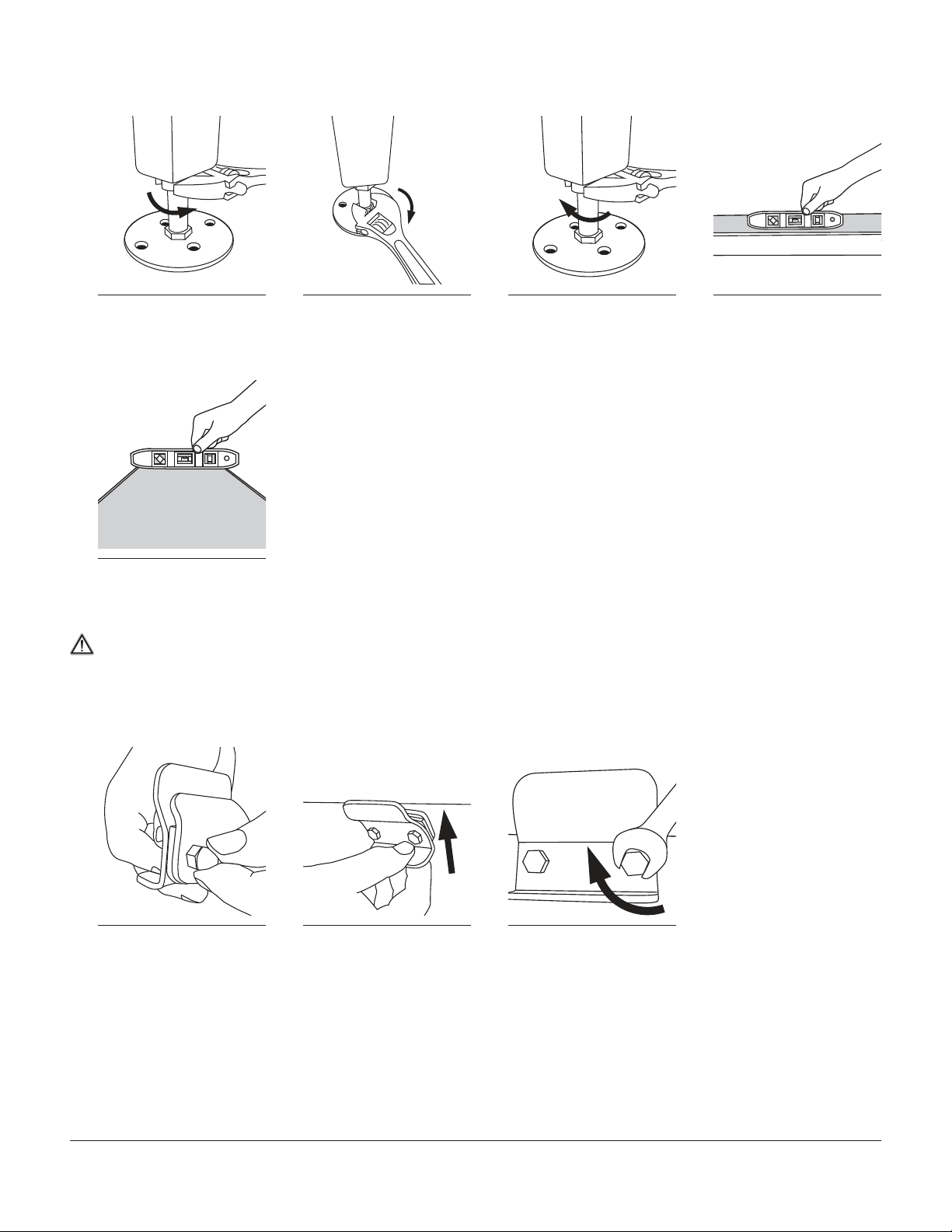

10 HC200 Conveyors | Installation & Maintenance Instructions

Belt Tracking

>For best results, make adjustments to only one side.

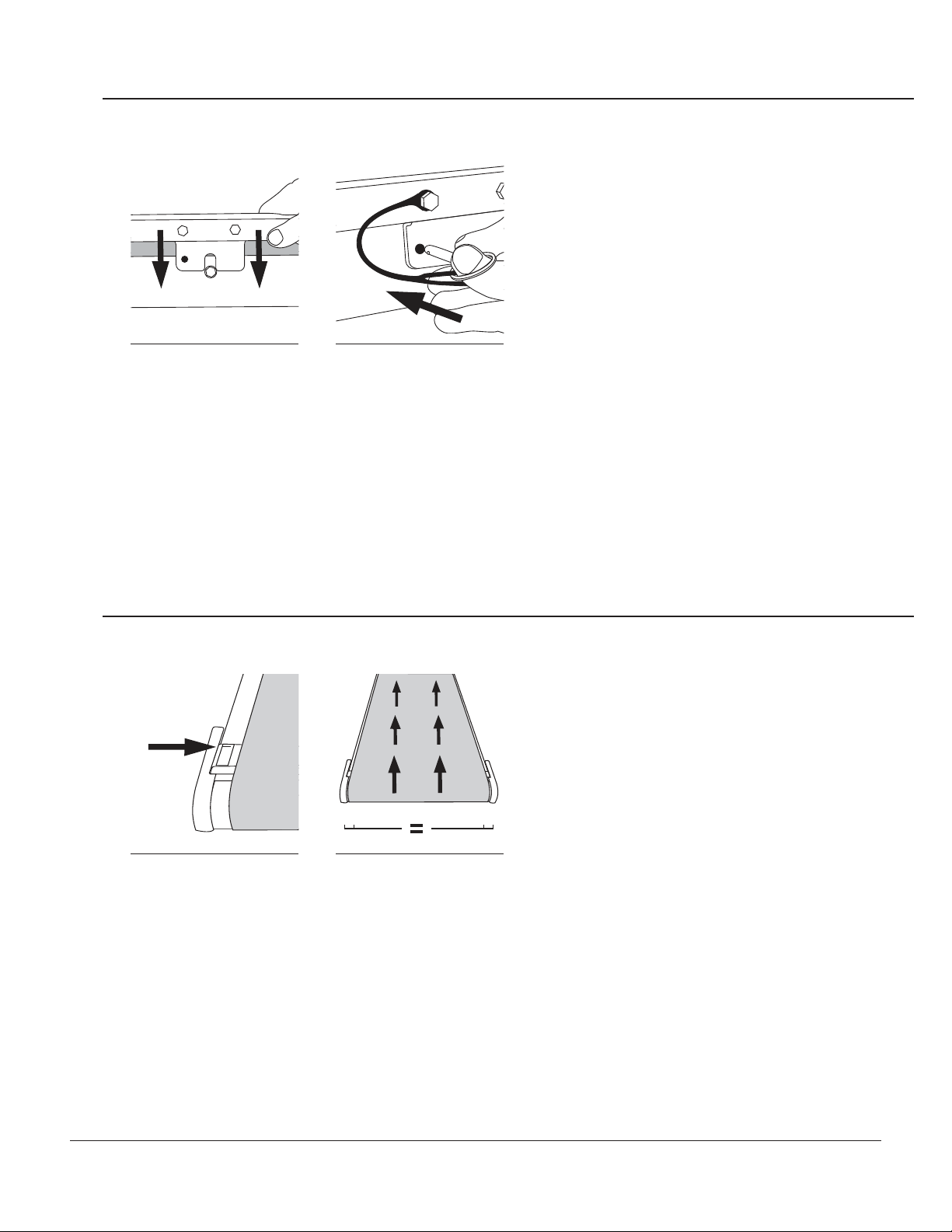

uBelt Tracking at Tail End

2

x

1Pull both pins in tail assembly. 2Flip tail assembly into disen-

gaged position. 3While holding a 10mm

wrench on nut under frame,

loosen hex head screw on tension-

ing window. (Do not remove)

4Lower tail assembly back into

engaged position.

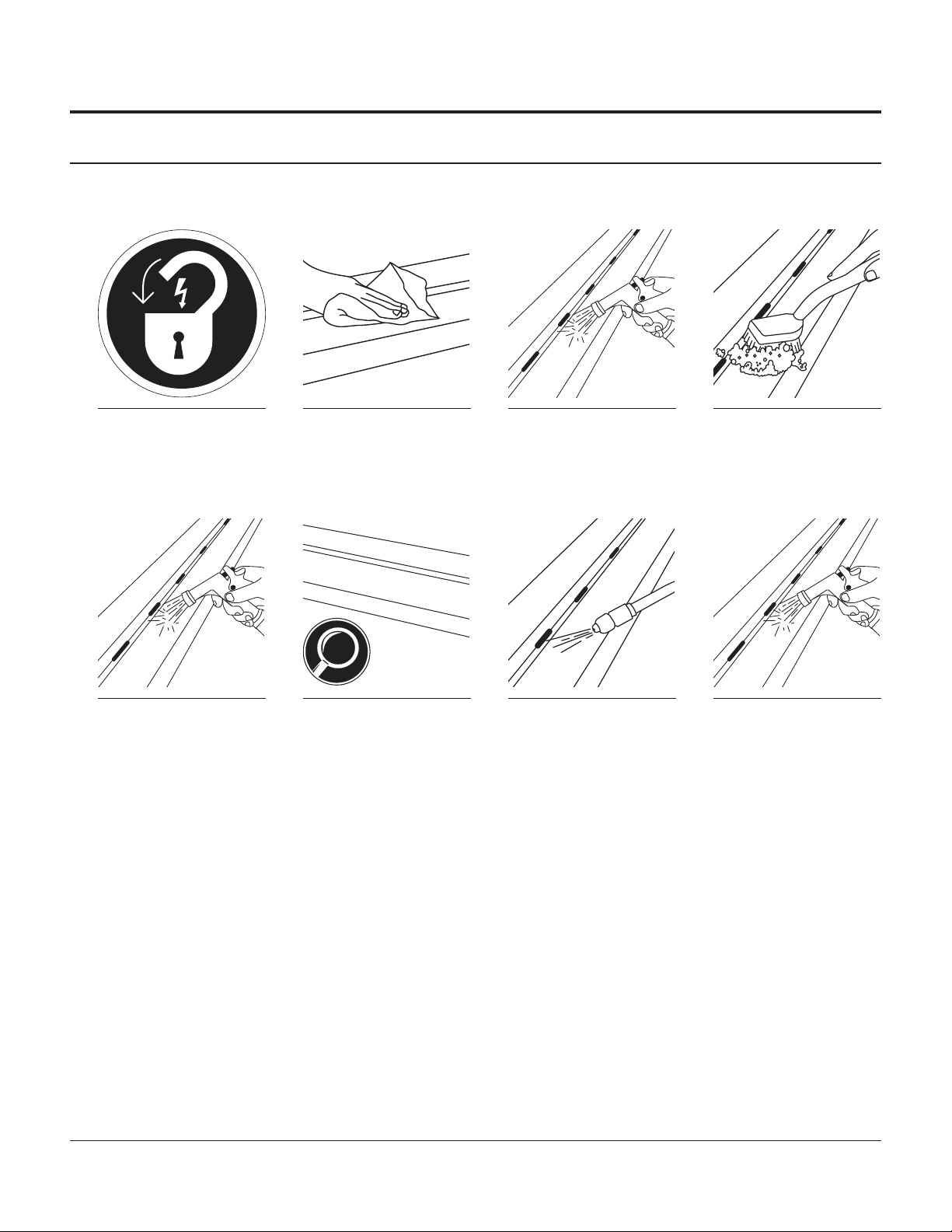

5Rotate tensioning window into

open position. 6Rotate tensioning screw to

make tracking adjustments.

(Moving tail out will move belt away

from bearing plate on that side)

7Run conveyor and let it make

several revolutions to ensure

belt is centered on frame and

pulley.

8Rotate tensioning window

back into closed position.

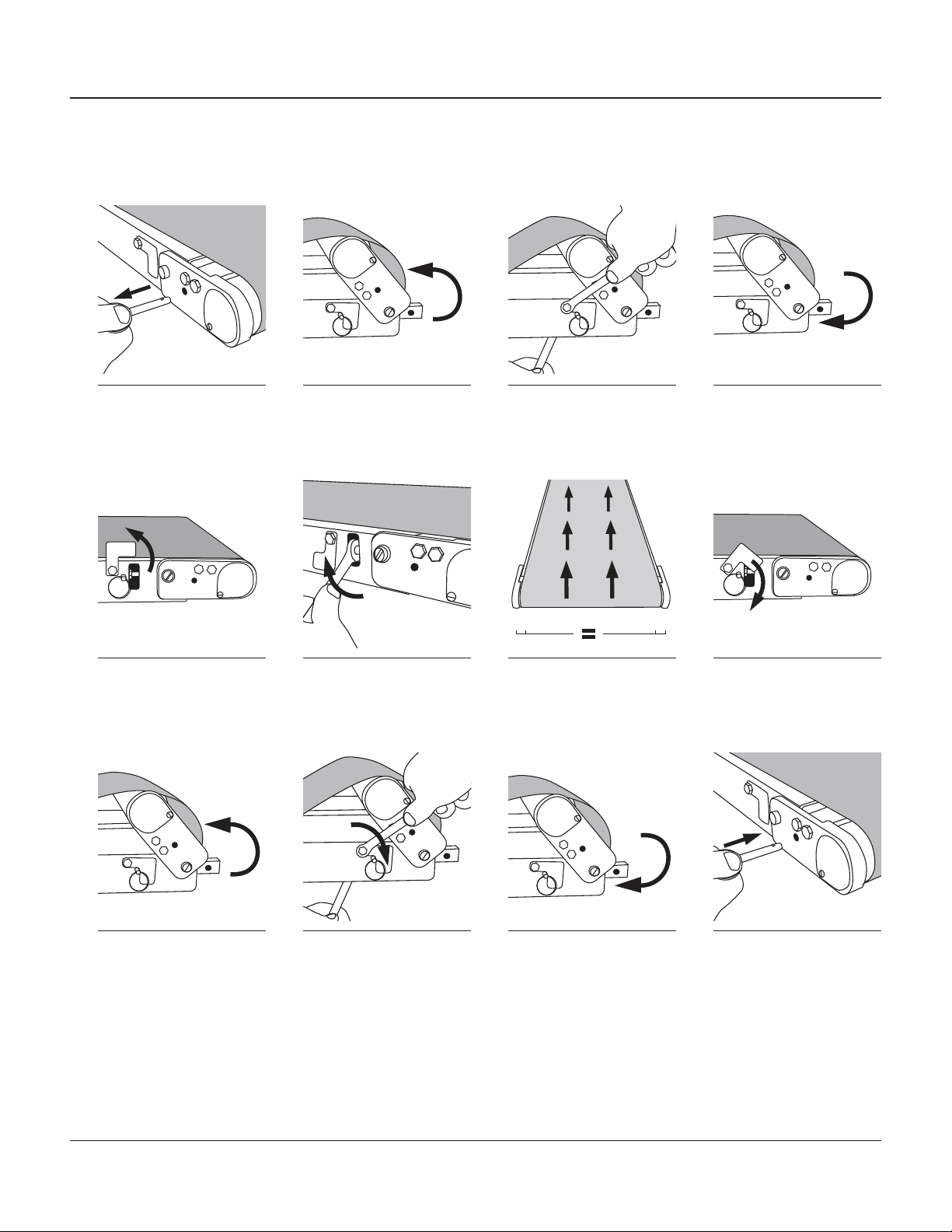

2

x

9Flip tail assembly into disen-

gaged position. 10While holding a 10mm

wrench on nut under

frame, tighten hex head screw on

tensioning window.

11Lower tail assembly back

into engaged position. 12Re-insert both pins into

tail assembly.