MDO_P1P44F-010: Operator Manual

1/2

Table of Contents

MDO_P1P44F-010: Operator Manual 1 .............................................................................................

1. Informations 2 ................................................................................................................................

1.1 Release 2 ....................................................................................................................................

1.1.1 Specifications/Copyright 2 .....................................................................................................

2. General features 3 .........................................................................................................................

2.1 Description 3 .............................................................................................................................

2.2 Workings 3 .................................................................................................................................

2.3 Options 3 ....................................................................................................................................

2.4 Features 3 ..................................................................................................................................

2.5 Executable working 3 ...............................................................................................................

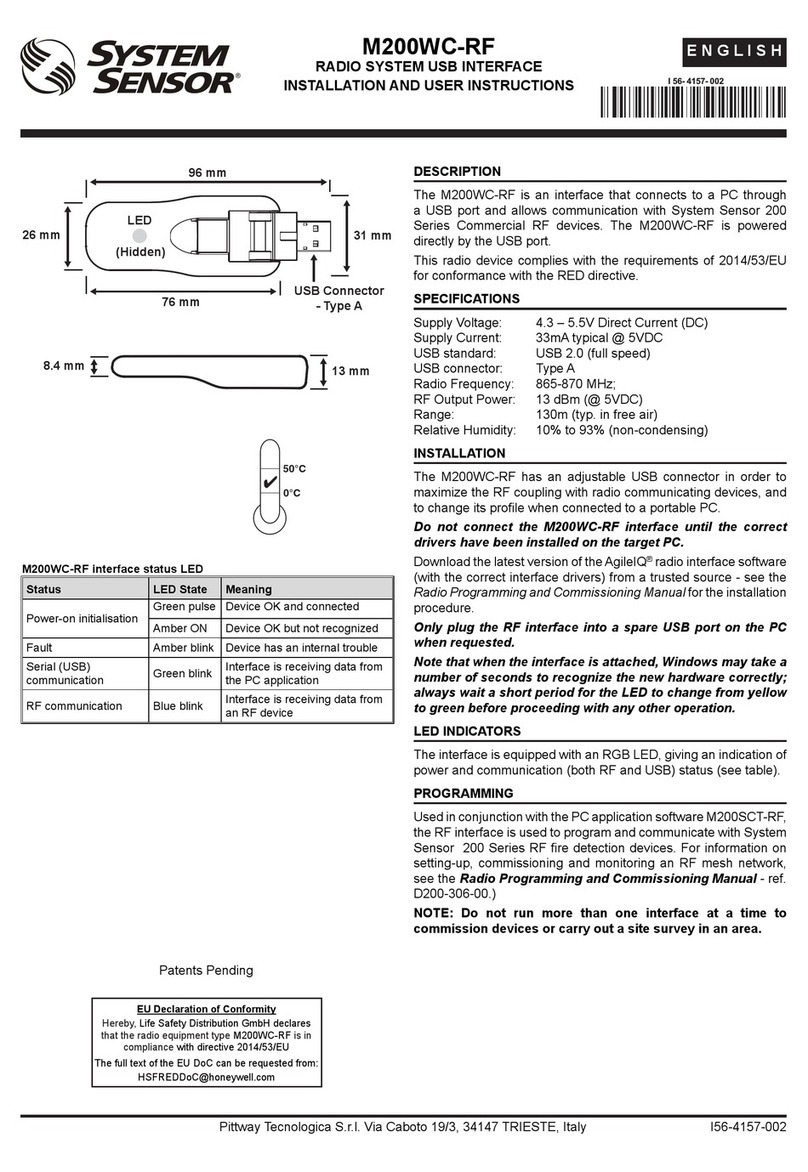

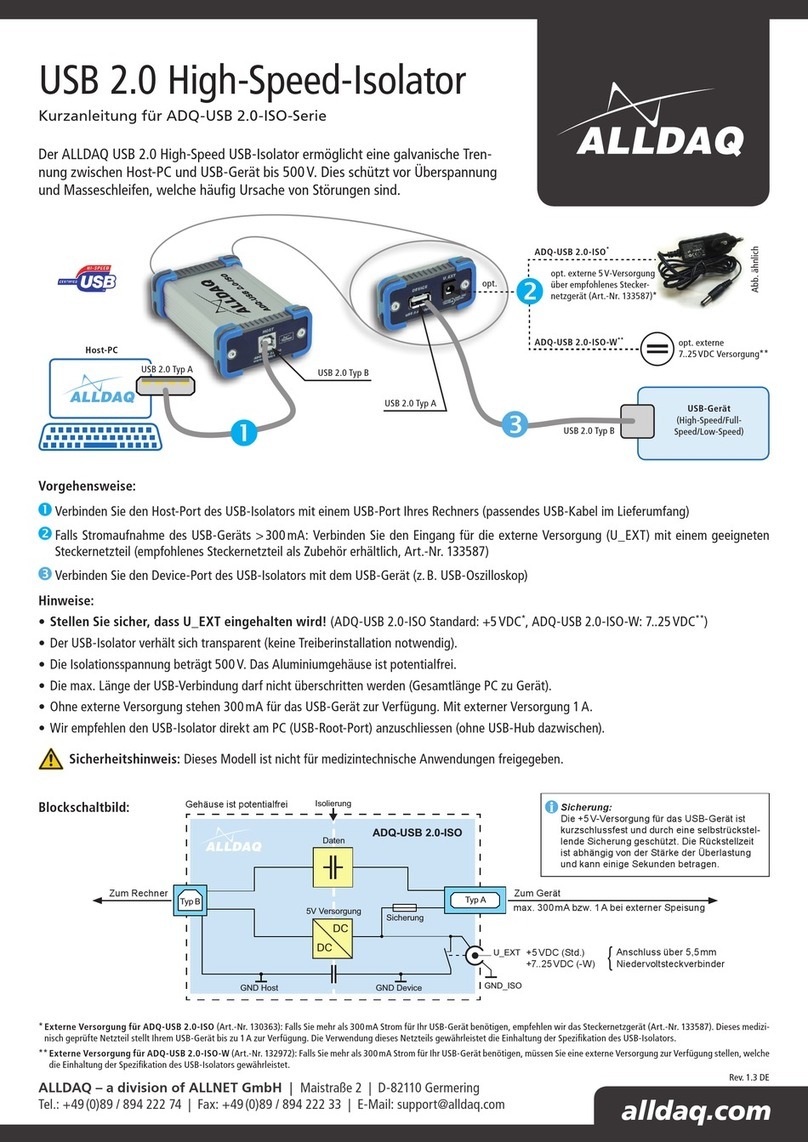

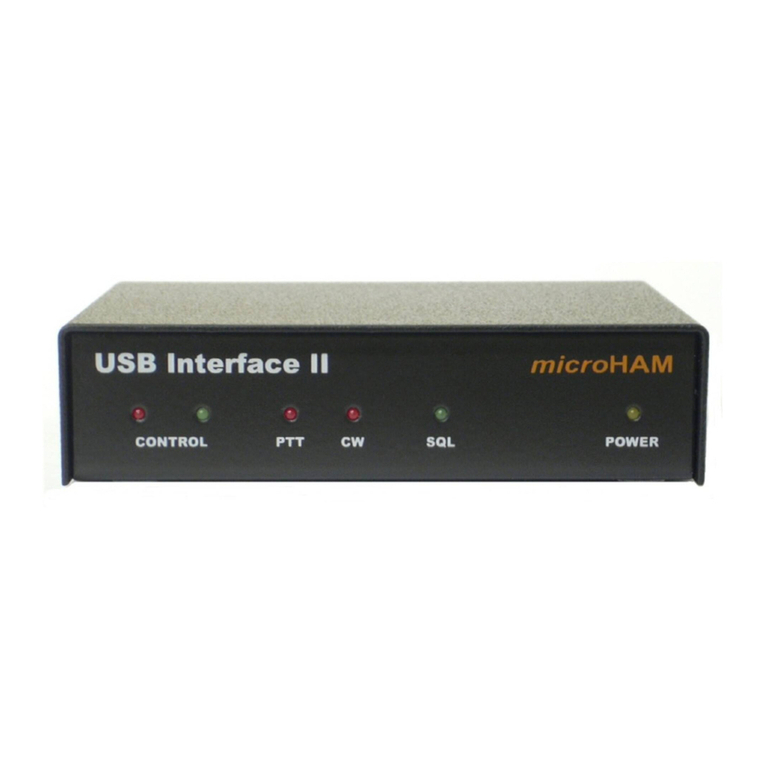

3. Hardware 5 ......................................................................................................................................

3.1 Function and LED keys 8 .........................................................................................................

3.2 Symbols and keys 8 ..................................................................................................................

3.3 Startup 9 ....................................................................................................................................

4. Main menu 10 ..................................................................................................................................

5. Homing 12 .......................................................................................................................................

5.1 Homing procedure 12 ...............................................................................................................

5.2 Error Delta 13 ............................................................................................................................

6. Machine datas 14 ...........................................................................................................................

7. Bottom bar 15 .................................................................................................................................

8. Manual/Semi-Automatic 16 ...........................................................................................................

8.1 Semi-Automatic Execution 20 .................................................................................................

9. Reset axes 21 ..................................................................................................................................

10. Restart working 22 ......................................................................................................................

11. Muliple Cuts/Automatic 23 ..........................................................................................................

11.0.1 Without table rotation 25 .....................................................................................................

11.0.2 With table rotation 25 ..........................................................................................................

11.0.3 Y-axis end position page 26 .................................................................................................

11.0.4 Axes parameters 26 .............................................................................................................

11.0.5 Working parameters 28 .......................................................................................................

12. Tilted Cuts/Automatic 29 ............................................................................................................

12.0.1 Y-axis end position page 32 .................................................................................................

12.0.2 Working parameters 32 .......................................................................................................

13. Flattening 33 .................................................................................................................................

13.0.1 Working parameters 35 .......................................................................................................

13.0.2 Axes parameters 35 .............................................................................................................

13.0.3 Working parameters 35 .......................................................................................................

14. Programming and executing profiles 36 ..................................................................................

14.1 Program list filtering 37 ........................................................................................................

14.2 Profiles 38 ................................................................................................................................

14.2.1 Profiles - CAD 39 ..................................................................................................................

14.2.2 Profiles - parameters 43 .......................................................................................................

15. Execution 45 ..................................................................................................................................

15.1 Program execution 45 ............................................................................................................

15.1.1 Profile execution 47 .............................................................................................................

15.1.2 Axis parameters 47 ..............................................................................................................

15.1.3 Working parameters 48 .......................................................................................................

16. Alarms 49 .......................................................................................................................................