INTRODUCTION

Liquid laminator is one kind of machine, which uses special water-soluble liquid to spread on picture surface and drying it

quickly; thereby forming a protecting lm on the picture surface. It is widely used in the post-production of outside / inside

advertisement and vehicle body advertisement.

Liquid lm is formed directly on the picture surface, so the lm thickness can be controlled as thick as it can, and axed

rmly.

FMJ-3300-WL liquid laminat ing width could reach 3.2 meters (126in), especially t for the wide-breadth advert isement

picture. In order to save energy, you may use right part of the heating box to reduce the power (50%) when the picture

width is less than 1.6 meters.

This machine works simply and safely with low noise. It uses liquid water-soluble lm, which is innocuous and avorless,

also be clean out without pollution. It is good for protecting environment very well.

This machine can carry out laminating, drying and winding-up in one process, thus it save time and space greatly. Due

to the price of liquid lm is lower than cold laminat ing lm, this make output rate is very high. Using liquid laminator can

reduce the lm laminat ing cost much more than ever before. You can get back your investment in a short time.

The picture laminated will show more bright-color and beautiful, with the function of waterproof, sun proof, and anti-

ultraviolet radiat ion, hence prolong its lifetime much more, of course the liquid lm quality, which you select, is vital to the

picture.

Choosing this liquid laminator and liquid lm with high quality, you will get a rst-level advertisement picture and benet

from it greatly.

Before operating FMJ-3300-WL liquid laminator, please read the instruction carefully in order to operate correctly the

machine. Our company will also provide free-charge training for operator.

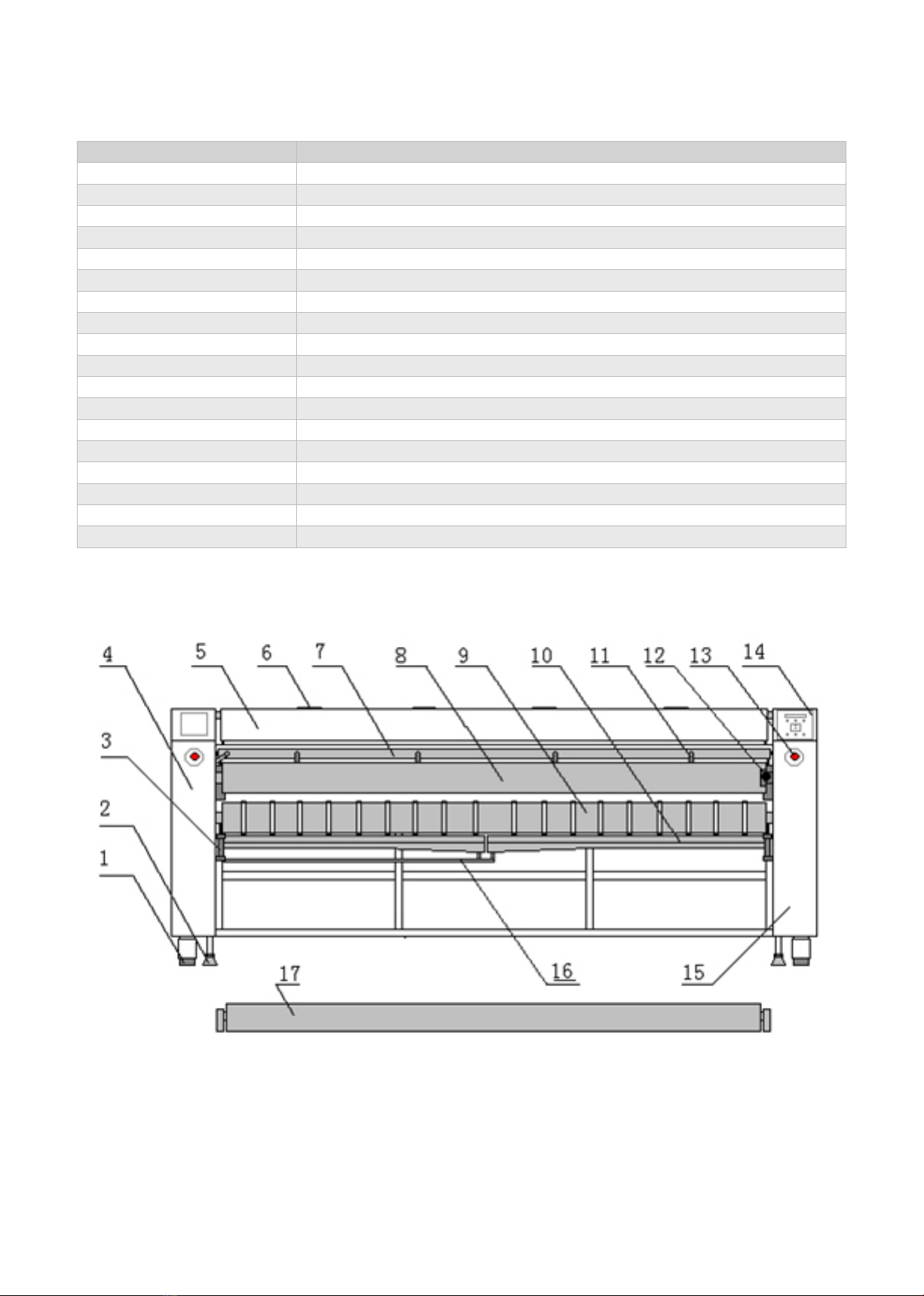

Ⅰ. Mounting (Installation)

When opening the package, please rst remove the attached ttings for this machine, and then dismount the xed 1.

chassis’s bolt and clamping-plate, then remove the wood chassis supporters, let the four truckles falling on the oor.

After that, you can use crane or manpower to move the machine to the ground, and put it in its work area.

Notice:

① For its huge body and heavy weight, careless removing may injure human body or make damage to the machine.

Moving the machine should be in charge by someone who has pract ice experience.

② Try not to move this machine on unevenly ground.

Place this machine in an area with sucient operat ing space. The operat ion area should keep cleanness, vent ilation, 2.

lighting sucient and far from dirt, dampness and causticity, also conform to the safety requirement of reproof.

After the machine placed in the work place, please mount and adjust the four foundation bolts for leveling the machine3.

in ground.

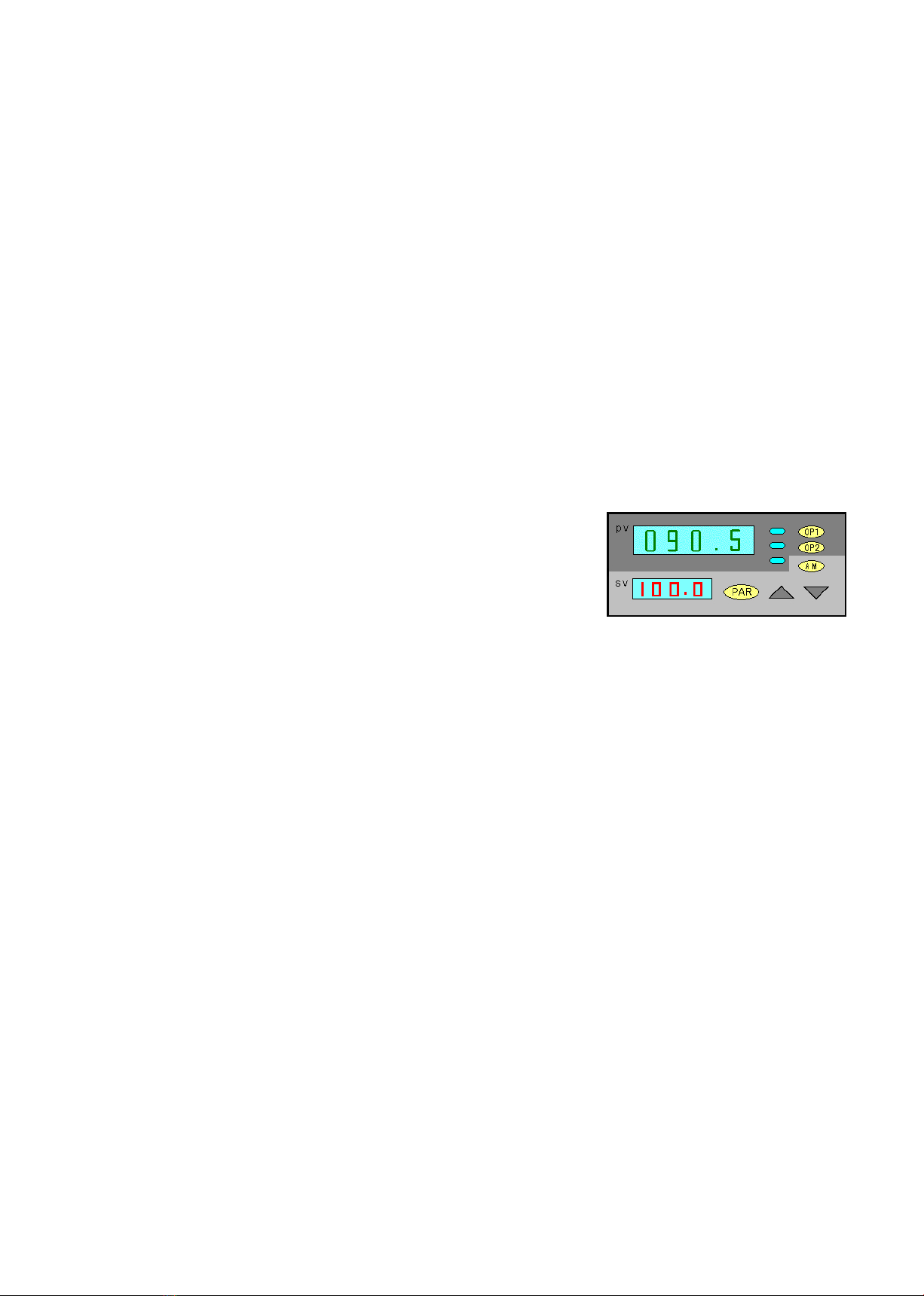

Switch on power supply: This machine uses 230 / 400V, 3W+N+PE, 50Hz. Its power is 12 kW, rated current 32A. Before 4.

switch-on, please check if voltage and current-carrying capacity of local power supply system conforms to the

requirement on the machine nameplate to ensure safety.

The wire of this machine should directly connect with air-breaker (user self-supply, 60227, IEC53, 5core, Cross area over 5.

4.0mm2), and PE wire must connect well with earth wire. It should not be connected with plug or socket.

•The power cord shall be earthed reliably, and the reliability of protective earth should be checked. Ought to

use the exible circuit conductor of more than 4.0mm2 to earth the equipment (the earthling resistance < 0.1Ω)

so as to insure safety in operat ion and to avoid static electricity.

Notice: the machine is equipped with earth-leakage circuit breaker; however the reliable earth wire is needed. Don’t lay

•

the power cables on the walkway or put things on them.

The machine shall be used below the ambient temperature 40°C.6.

Environmental humidity: 30%-70%. Avoid using in place with higher temperature, humidity, and more dusts.7.