Page 6 of 8 dc_102019.pdf

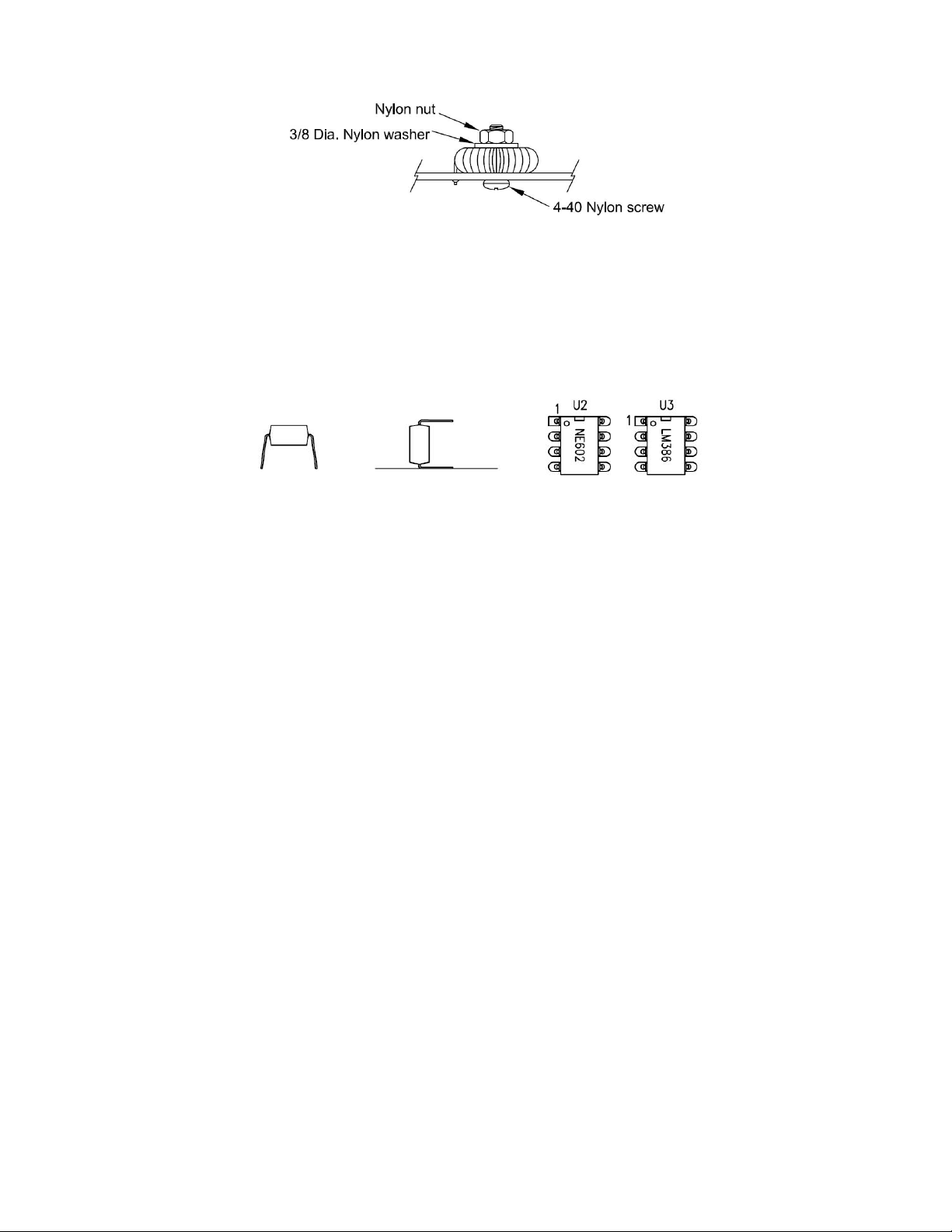

[ ] Retain T1and L1 with the nylon hardware as shown in the graphic below. Feed the screw from

under the pcb.

[ ] Install VR1,2,3, 10K pcb mounted potentiometers

[ ] Attach the four self adhesive rubber feet to the corners on the bottom of the board where

indicated by the silkscreen.

[ ] Power up the receiver with 12VDC via the DC power jack. The center pin is“+” on J2.

Check for ~+7.5V on pin 8 of U2, and ~9.0V on pin 6 of U3. If all is ok, power off, and install U2

and U3 into the socket noting the position of pin 1 shown in the graphic below.

When inserting IC the pins are flared so that they can be retained by auto insertion tools. Gently rock it

on a flat surface so the pins are parallel and it will insert into the socket more easily.

Circuit description:

The conversion of the incoming modulated signal to baseband, is done in a single frequency

conversion. This avoids the complexity of the superheterodyne's two (or more) frequency conversions,

IF stage(s), and image rejection issues. The incoming rf is amplified by the 2N3904 and passes thru the

tuned network and then is fed directly into the NE602/612 frequency mixer, just as in a

superheterodyne receiver. However unlike the superheterodyne, the frequency of the local oscillator is

not offset from, but identical to, the received signal's frequency. The result is a demodulated output just

as would be obtained from a superheterodyne receiver, except you have both sidebands to choose

from. An enclosure would help in any frequency stability issues encountered by temperature changes.

Alignment:

The DC receiver has connections for our Digital Dial, or you can attach a frequency counter to the

Digital Dial signal pad, however you can set up the unit using a nearby receiver loosely coupled.

Connect the DC receiver to +12.0-13.5V, and to an antenna and peak C17 for max. signal or noise. If

you do not have a digital dial connected, a nearby receiver, loosely coupled, will pick up the local

oscillator and help you setting the overall bandspread range. While every attempt has been made to

optimize the parts to land the bandspread starting at the center of any given band, component

tolerances can require some adjustment. The component that controls the overall "center" of the

bandspread is L1. If needed, start by compressing or spreading the turns on L1, as that can help you

center the overall bandspread of the spectrum you desire. If that does not get you to the band portion

you want, one turn either way on L1 can move the center ~100KHz. Add a turn you lower it, subtract a

turn to raise it. R4 and R5 influence the red led used as a varactor diode. Increasing R4 will give you

less bandspread, and increasing R5 will give you less fine tuning range. D4 led is part of the AGC

system. It will flash at times of intense signal pops and smooth out extreme overload. When in an area

of very heavy commercial SW broadcast interference, tune C17 for minimum interference.