Introducon

7

July 2013

Piano Acon Regulaon

Thisdiscussionisnotintendedtobeacompletecourseongrandaconregulaon,butrathermayprovehelpfulinrestoringtheacontoproperperformance.Proper

alignmentofaconparts,andkeyeasingareallveryimportantstepsintheregulaonprocedure.Thefollowingprocedureassumesthatthispreliminaryworkhasbeen

checkedandperformedasnecessary.Beforeremovingtheaconfromtheaconcavity,evaluateaconregulaon.Iftheaconisnotwellregulated,properperfor‐

manceofthesystemcannotbeexpected.

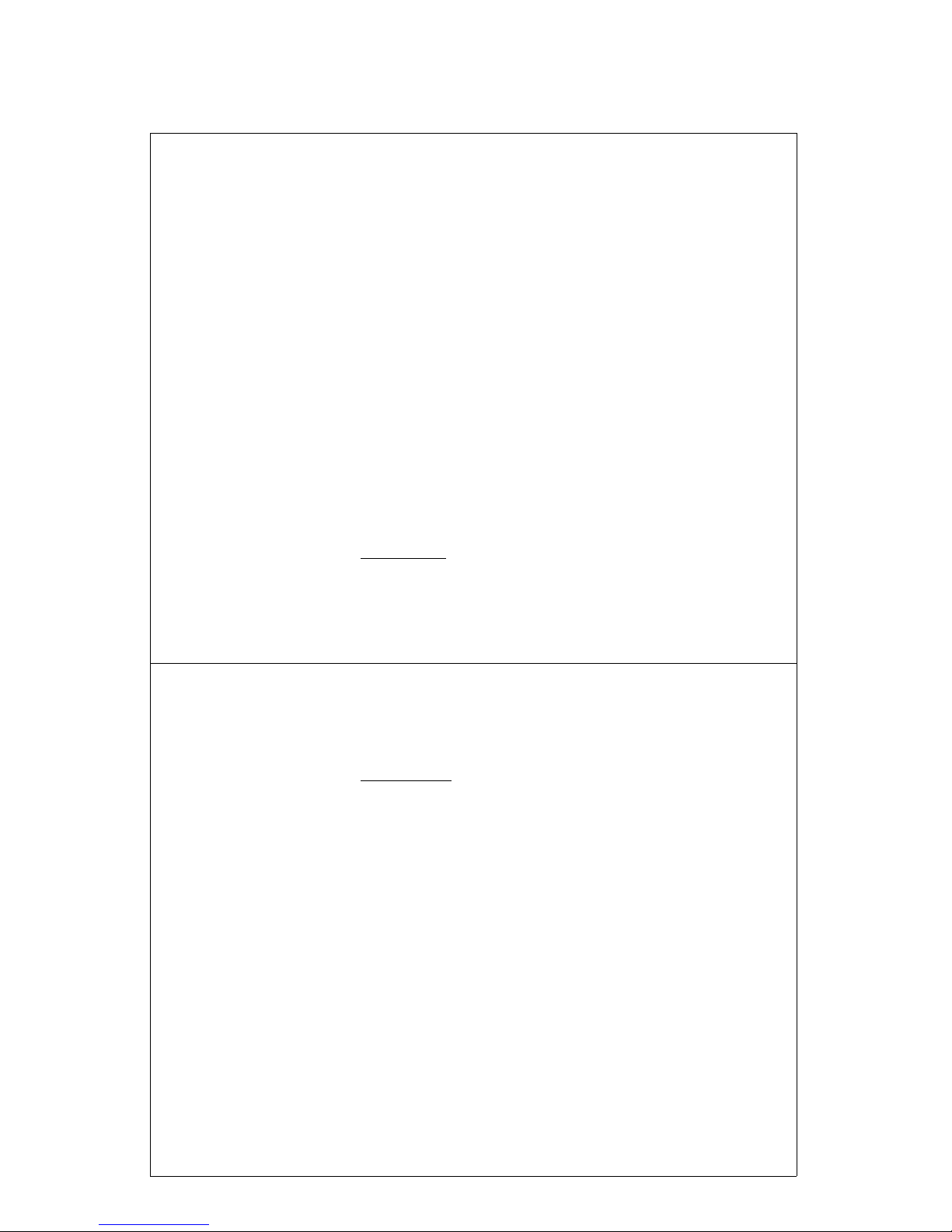

DuringtheinstallaonprocessofthePNOmaonIIPlayerSystem,itisquitepossiblethataconregulaonwillbedirectlyaffected.Aporonofthekeyframeandback

railclothwillberemovedsothatthenotesolenoidplungerscancontactthekeytails.Thisoperaonmaycausethekeytailstobelowerthantheiroriginalposion.The

resultoflowerkeytailsisanincreaseinbothkeyheight,andhammerstrikedistance.Restoringthestrikedistancetospecificaonsbyturningoutthecapstanscrewsis

nottheproperremedy.Alwaysre‐workthebackrailheightsothatthekeyheightisatitsoriginalposion.

‐Arethekeyslevel?

‐Dothehammersletoff1/8inthebass,taperingto1/16inthehightreble?

‐Isthedrop1/16belowthepointoflet‐off?

‐Isthehammerlinestraight?

‐Arethehammershanksapproximatelyoneshankthicknessabovethehammerrestrail?

‐Isthereadequateaer‐touch?

Withtheacononaflat,cleanworkbench,measureandrecordthefollowing:

Naturalkeyheightatbassandtrebleends.

Sharpheightabovenaturals.

Keydip;bothnaturalsandsharps.

Theheightofthefirstandlasthammersineachseconoftheacon.

Replacethekeysandaconstackontheaconframe.Refertotheregulaonmeasurementsrecordedearliertoseeifregulaonhasbeenaffectedbythemodificaons

totheaconframe.Ifkeyheight,keylevel,orstrikedistancearedifferentthanpreviouslyrecorded,stepsmustbetakentorestoreproperregulaon.

Torestorekeyheight,replacethebackrailclothwithoneofathickerdimension.Removetheaconstackandkeys.Aerremovingtheoldbackrailcloth,besurethat

alltracesofgluehavebeenremovedfromthebackrail.Replaceafewoftheendkeysandtryvariousthicknessofbackrailcloth,withoutglue,toballparkthecorrect

keyheight.Lightfingerpressureonthecapstanscrewwillapproximatetheforcethatisnormallyonthecapstan.Setkeyheightwiththebackrailclothat,orslightly

belowthedesiredkeyheight.

Whenyouaresasfiedthatyouhavethebestchoiceofbackrailcloth,gluethematerialtothebackrail,leavingtherearedgeunglued.Nameboardfeltisavailableina

fewdifferentthicknesses,andcanbeusedforfineadjustmentswhengluedunderthebackrailcloth.

Althoughkeyheightcanbereestablishedquiteaccuratelyusingtheaboveprocedure,somekeylevelingistobeexpectedwhenreplacingbackrailcloth.

Rememberthatsubsequentaconregulaonadjustmentswillaffectthosealreadyperformed.Topreparetheaconforfineregulaon,dothefollowingquickly:

Checkorsetrepeonleverheightsoitisslightlyhigherthanthejack.Duringyourfinalregulaon,tripthejacktenderwithyourfingerandreleaseitslowly.Ifregulat‐

edproperly,youwillbeabletofeelthejackbrushingtheknuckleasitisreleased.Thejackmustreturncompletelyundertheknuckle.

Setstrikedistanceto13/4.Besurethathammershanksareabovetherestrail.

Checkorsetjackposionsothatthebackedgeofthejackisalignedwiththebackedgeoftheknucklecore.

Setlet‐off1/8fromstringinthebass,taperingto1/16inthehightreble.Makesurethatyouhavesomedropaerescapement.

Setdropto1/16belowlet‐off.

Withtheabovepreliminarystepscompleted,levelkeysasnecessarytotheirfinalspecificaon.Notethatwithkeyheightatthesamespecificaonasitwasbeforeac‐

onframemodificaon,keydipshouldbecorrect(assumingthatthedipwascorrectpriortotheinstallaonprocedure).Also,damperlimingisreestablished.

Checkorsetrepeonspring.Thespringshouldcarrythehammerupwardwithasteadymoon,withoutkicking.

Withthepreliminaryaconregulaondone,youarereadytoestablishthestrikedistanceandkeydipmeasurementsthatwillresultinproperaer‐touch.Sincethekey

height/keydiprelaonshiphasbeenreestablished,considervaryingonlythestrikedistancetogettheproperaer‐touch.Ifyouareworkingonanolderinstrument,

considervaryingbothstrikedistanceanddiptoarriveatanacceptablecompromise.Selectsamplekeyswithwhichtowork,likethefirstandlasttwokeysineachsec‐

on.

Depressyourfirstsamplekeyveryslowly,stoppingitsmovementjustaerletoff.Looktoseeifthereisaddionalkeytravelle.Ifthereisnoaddionalkeytravel

aertheletoffpoint,thereisnoaer‐touch.Keydipwillhavetobeincreased,orstrikedistancewillhavetobedecreased.Ifthereistoomuchaddionalkeytravel

aertheletoffpoint,thehammermayblockagainstthestringswhenthekeyisplayedfullyintoitsdip.Keydipwillhavetobedecreased,orstrikedistancewillhaveto

beincreased.Besurethatthesharpshavethesameaertouchasthenaturals.Asasecondcheck,seethatwiththekeyfullydepressed,thereissllsometravelleat

thejacktender.

Whenyouhavethekeydip/strikedistanceestablishedonyoursamples,setyourkeydiptoyourestablishedspecificaonuniformlythroughouttheacon.Youarenow

readyforthefinalregulaon.

Usingyournewstrikedistancemeasurements,carefullyrepeattheaboveoutlinedstepsforthefinalme.