Installation, Operating & Maintenance Manual

7 10/25/2004

DETAILED MANUAL

Table of Contents

Models And Description Of The Components........................................................................................................8

How The HU315 Works..........................................................................................................................................9

Installation ............................................................................................................................................................10

Positioning........................................................................................................................................................10

Removing the front cover.............................................................................................................................10

Fastening to the wall....................................................................................................................................10

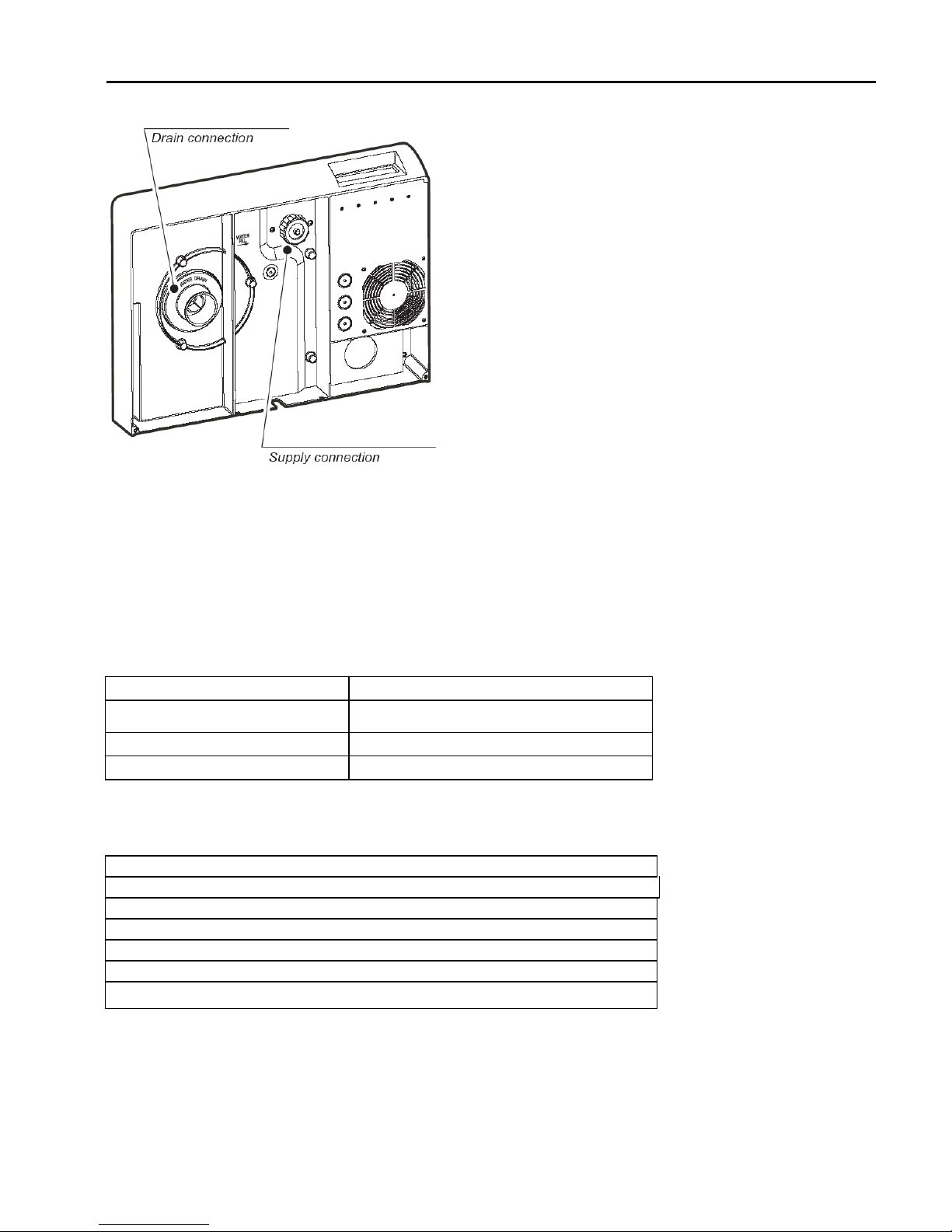

Plumbing ..........................................................................................................................................................11

Water supply................................................................................................................................................11

Water drain ..................................................................................................................................................11

Power wiring.....................................................................................................................................................13

Control wiring ...................................................................................................................................................14

ASWH / ASDH – ASDH / ASDC Wall – Duct Temperature/Humidity Sensors ...........................................15

Start-Up ................................................................................................................................................................15

Startup Checklist ..............................................................................................................................................15

The HumiControl Controller .............................................................................................................................16

Start-up Procedure...........................................................................................................................................16

Starting with a new cylinder .........................................................................................................................17

Operation..............................................................................................................................................................17

Display Information ..........................................................................................................................................17

Changing The Set Point ...................................................................................................................................17

Activating Manual Drain ...................................................................................................................................17

Accessing/Changing Configuration Parameters ..............................................................................................17

Notes about special parameters ......................................................................................................................21

STANDARD FACTORY SETTINGS ................................................................................................................22

Seasonal Shut Down........................................................................................................................................23

Resetting the Hour Counter .............................................................................................................................23

Alarms ..............................................................................................................................................................24

Trouble-Shooting..............................................................................................................................................28

Resetting Factory Defaults ..........................................................................................................................30

Maintenance .........................................................................................................................................................30

Periodic checks ................................................................................................................................................30

Cylinder maintenance ......................................................................................................................................31

Replacing the cylinder .................................................................................................................................31

Maintenance of the other plumbing components ........................................................................................31

Replacement Parts...........................................................................................................................................32

Three Phase Humidifiers .............................................................................................................................32

IMPORTANT: BEFORE beginning installation:

•Check for shipping damage to cartons. Mark the shipping waybill accordingly

•Open cartons and check for any hidden damage. Mark the shipping waybill accordingly.

•Check packing slip to ensure all items have been received. Notify Quatro of any shortages or damaged

parts. You must notify Quatro within 5 working days of any shortages.