North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rim

armstronginternational.com

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit armstronginternational.com for up-to-date information.

3

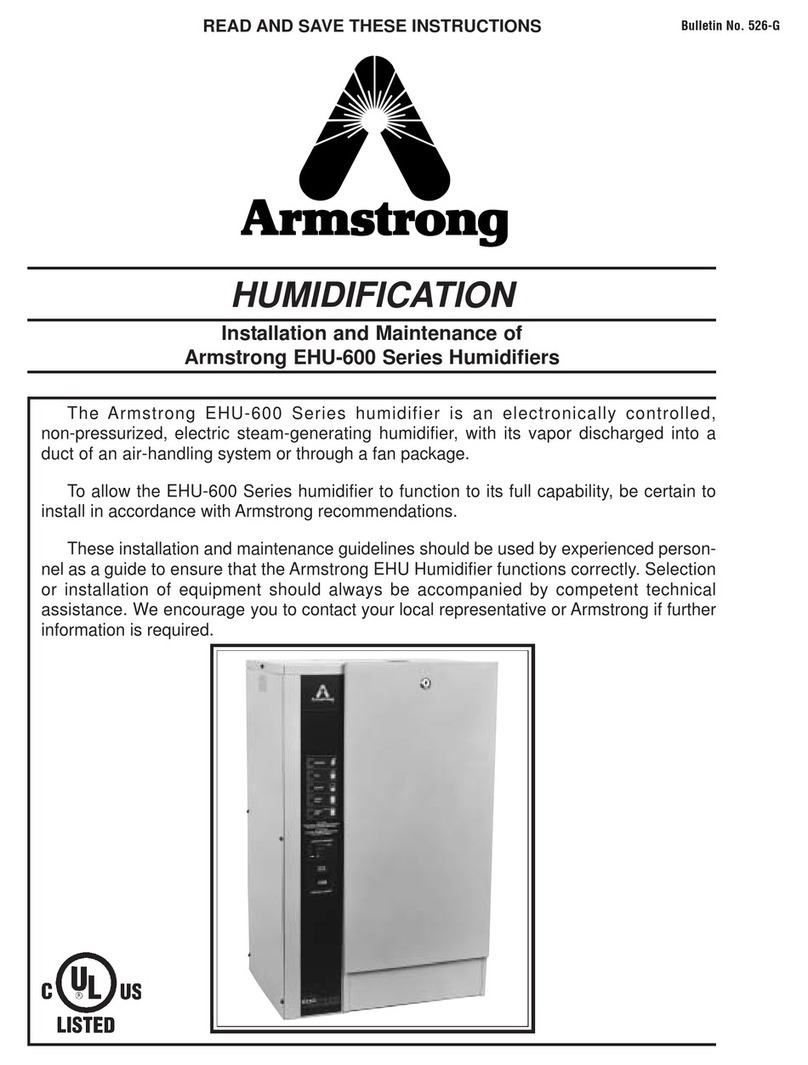

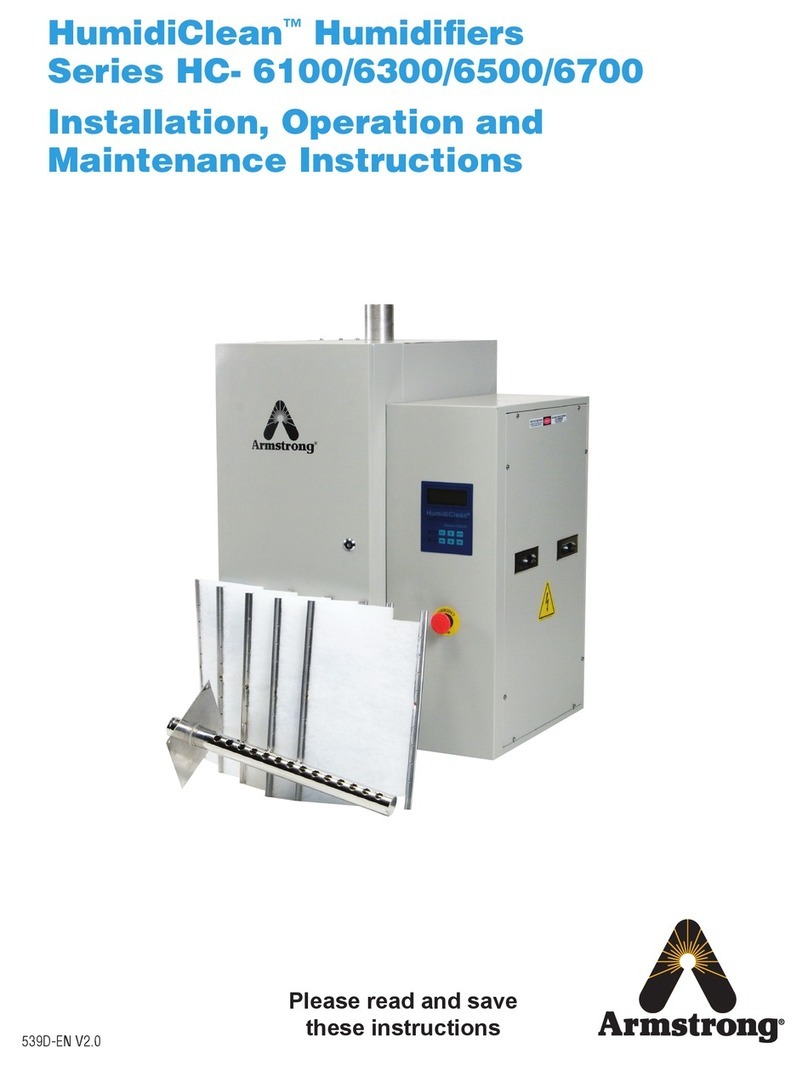

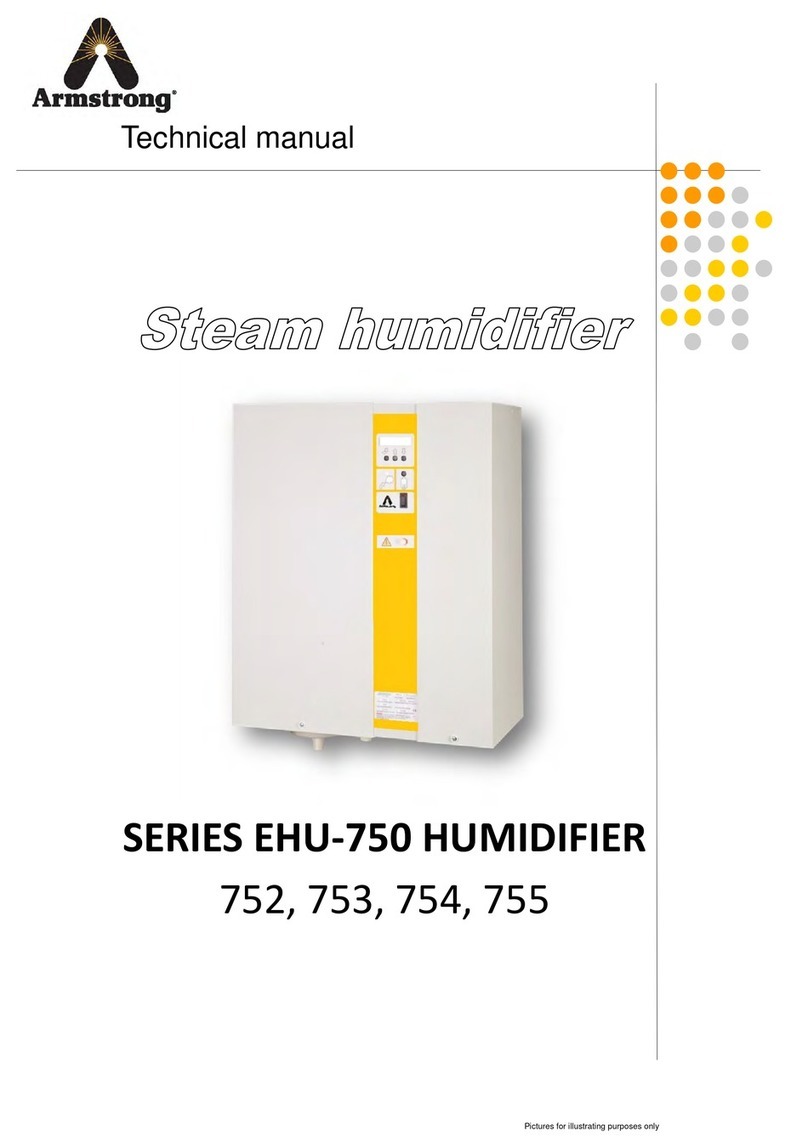

Series EHU-800 Humidifiers

The Armstrong Series EHU-800 humidifier is a non-pressurized, steam-generating humidifier that is controlled electronically.

The vapor produced by the EHU-800 is discharged into the duct of an air-handling system or through a fan package. The

Armstrong Series EHU-800 consists of three models: EHU-801, 803 and 804. The maximum capacity of the series is 242

lbs/h (110 kg/h).

To allow the Series EHU-800 humidifier to function to its full capability, be certain to install it in accordance with the

following Armstrong recommendations. For further assistance, please contact your local Armstrong representative.

The EHU-800 installation, operation and maintenance manual contains all details necessary for the planning and installation

of the EHU-800 humidifier. Commissioning and maintenance details are also included within this document.

The EHU-800 installation, operation and maintenance bulletin manual is intended to be used by engineers and properly

trained technical personnel. Maintenance, servicing or repair work must only be performed by skilled and qualified

personnel. The customer will be responsible for ensuring their suitability any risks or hazards, especially when working from

ladders or towers should be identified by a skilled and Health and Safety representative and effective control measure put in

place.

No liability will attach to the Distributor if any damage, injury or accident is attributable to inattentive, inappropriate,

negligent or incorrect operation of the machinery whether or not caused deliberately. Always isolate all electrical and water

supplies before commencing any maintenance.

Every effort has been made to ensure details contained in this manual are correct, however in view of the wide range of

conditions experienced in air handling systems; the information provided should only be used as a guide. Please contact the

Armstrong factory if any doubt.

Please read and save these instructions.

Please complete the prestart-up checklist

located at the back of this document.

Retain checklist for future reference.