QUATROS QS19134 User manual

a

a

PW TECHSAM Woch Sp. J. tel. 81 444-63-73

ul. Warszawska 131 tel. 81 443-08-12

20-824 Lublin fax 81 458-38-19

IMPORTER:

OWNER’SMANUAL

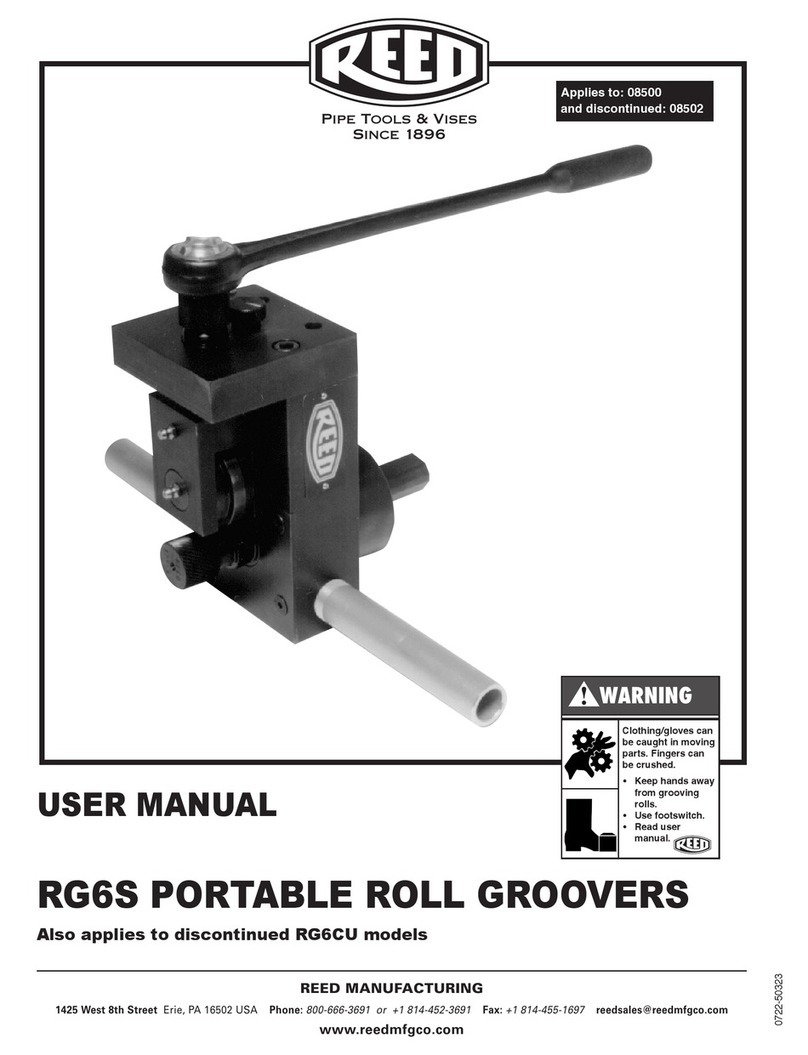

HYDRAULIC TROLLEY JACK LOW PROFILE, DUAL PUMP 3T

QS19134

DESCRIPTION

Hydraulic Trolley Jack Low Profile Dual Pump 3T QS19134: Capacity: 3T | Min. height: 75mm | Max. height: 500mm | Weight: 33kg

SAFETY INSTRUCTIONS

WARNING

-This jack is a lifting device, designed ONLY for lifting part of the total vehicle (i.e one wheel). Do not move or dolly the

vehicle while itis on the jack. Never use lift device to raise any others load.

-Position this jack to ONLY lift on the areas of the vehicle as specified by the vehicle manufacturer.

-After lifting the vehicle, ALWAYS support the load with appropriately rated vehicle support stands BEFORE working on the

vehicle.

-Do not overload this jack beyond its rated capacity. Overloading can cause damage to or failure of the jack.

-This jack is designed ONLY for use on hard level surfaces capable of sustaining the load. Use on other than hard level

surfaces can result in jack instability and possible loss of load.

-Center load on jack saddle BEFORE lifting vehicle. Off-center loads and loads lifted when the jack is not level can cause loss

of load or damage to the jack.

-Study, understand and follow all instructions in this manual BEFORE operating the jack.

-Failure to heed this warning may result in loss of load, damage to the jack and/or jack failure resulting in personal injury or

property damage.

OPERATION

WARNING! Ensure that you read, understand and apply the safety instructions.

ASSEMBLING HANDLE

Insert handle piece (part no. 19) into middle handle piece (part no. 18) making sure holes

line up for retaining clips. With the jack sitting on its wheels on a flat surface, slide

assembled handle into handle base (part no. 20), rotate until the square-shaped hole slips

over shaft in handle base. Loosen ½ turn handle should rotate easily.

At the rear of jack a large metal clip holds handle base flat against the jack. While keeping

handle pushed down in compressed position, carefully remove clip by pulling out. Release

pressure on handle base and discard.

PREPARING WORK AREA

Before using jack to lift vehicle it is important to prepare work area properly. Follow this procedure each time the jack is used to

help prevent property damage and or serious injury.

1. Thoroughly inspect jack for damage or wear before each use. Briefly test operation of unloaded jack before using to lift. If

jack is damaged or is malfunctioning DO NOT LIFT ANY LOAD until the problem is corrected.

2. The Vehicle manufacturer’s owner’s manual should be consulted prior to the lifting of the vehicle. It will advise safety

precautions, jacking procedure, vehicle weight, recommended jack type, and location of jack support areas on vehicle. The

working load limit of the jack is 3000 kg. NEVER EXCEED WORKING LOAD LIMIT OF THE JACK.

a

a

PW TECHSAM Woch Sp. J. tel. 81 444-63-73

ul. Warszawska 131 tel. 81 443-08-12

20-824 Lublin fax 81 458-38-19

IMPORTER:

3. Clear children and other from work area before moving of lifting vehicle. Another adult should be nearby for extra safety

and assistance but must be clear of vehicle as it is moved or lifted. No person should remain in a vehicle that is being lifted.

No person should enter a vehicle which is supported by a jack or by vehicle support stands. No person should lean into

a vehicle which is supported by a jack or by vehicle support stands.

4. No person should get bodily under a vehicle that is supported by a hydraulic trolley jack.

5. Clear obstructions from work area, Working in tight or cluttered work areas is dangerous.

6. The hydraulic trolley jack should be used for lifting and lowering only. The raised vehicle should be supported on vehicle

support stands.

7. Be sure jack and vehicle are on solid, level ground such as paved on concrete driveway or garage floor. The hydraulic jack

should be used on a hard level surface and be free to roll during lifting and lowering. Uneven or sloped surfaces create

hazardous working conditions and dangerously impeded the function of the jack.

8. With vehicle in proper position, set vehicle’s parking brake or emergency brake and put gearshift in park (manual

transmissions should be placed in lowest gear). TURN VEHICLE IGNITION OFF AND TO THE “LOCK” POSITION making sure

steering wheel locks.

9. The unlifted wheels of the vehicle should be chocked. Do not rely on vehicle transmission or brakes to hold vehicles in

position. Chock all wheels of vehicle not being lifted off the ground to prevent vehicle rolling. Using wedge-shaped blocks

that the tyre cannot roll over, position one chock tight against the tyre in both forward and reverse rolling paths.

10. The load should by centrally located on the head cap. Off centre load can be unstable.

11. The hydraulic trolley jack should be used for lifting and lowering only; the raised vehicle should be supported on vehicle

support stands. Vehicle support stands (not included) will be needed to support vehicle once it is in raised position. Have

jack stands, vehicle support stands capable of supporting vehicle weight ready nearby for use. Read and understand jack

stand manufacturer’s instructions and safety information before use and before lifting the vehicle with this jack.

12. Plan location of jack beneath vehicle, making sure jack will be contacting only a jack support area of vehicle. Consult vehicle

owner’s manual for location of jack support areas.

LIFTING VEHICLE

Lifting a vehicle using a jack can be dangerous. Follow all instructions and precautions below. Do not lift any vehicle with its engine

running or start any vehicle that is supported by jack or jack stands.

1. With lifting arm completely lowered, roll jack into position beneath jack support area of vehicle.

2. Twist jack handle completely clockwise. Slowly pump handle until lifting head cap just begins to contact support area on

underside vehicle.

3. Inspect position of head cap beneath support area, making sure it is centered and properly engaging support area.

4. Continue pumping handle until vehicle is lifted to desire height. Pay attention to head cap position as vehicle is being raised

to be sure there is no danger of support area slipping off or lifting from the head cap.

5. Place jack stands under additional vehicle support areas.

6. SLOWLY twist jack handle counterclockwise to ease vehicle down onto jack stands.

WORKING ON VEHICLE

Any vehicle being supported by a jack or jack stands creates a potentially hazardous working environment. Do not move or roll

a jack that is supporting a vehicle. Never place any part of your body beneath a vehicle supported by a jack. Be careful of forces

applied to vehicle such as torque on a nut or bolt. These forces could cause vehicle to become unstable on jack stands if jack stands

are not properly placed. Do not turn vehicle ignition or attempt to start any vehicle supported by jack or jack stands.

LOWERING VEHICLE

Before lowering vehicle, be sure area under and near vehicle is clear of all persons and obstructions.

1. Reposition jack under same support area used to lift vehicle.

2. Twists handle completely clockwise. Pump handle until head cap just makes contact with support area under vehicle.

3. Check to be sure head cap is centered under support area. Slowly pump handle to lift vehicle off from jack stands.

4. Remove jack stands, setting them aside, well clear of vehicle.

5. With firm grip on jack handle, SLOWLY twist handle counterclockwise until jack just begins to lower.

6. Carefully control speed of descending vehicle. Lowering a vehicle too fast can cause property damage on injury.

a

a

PW TECHSAM Woch Sp. J. tel. 81 444-63-73

ul. Warszawska 131 tel. 81 443-08-12

20-824 Lublin fax 81 458-38-19

IMPORTER:

MAINTAINING OIL LEVEL

Important Note: When adding or replacing oil, ALWAYS use SAE 10 Hydraulic Jack Oil. DO NOT use hydraulic Brake Fluid, Alcohol,

Glycerin, Detergent Motor Oil and dirty oil. Use of an improper fluid can cause serious internal damage to your jack.

ADDING OIL

With head cap fully lowered & jack on level ground, remove Air Vent Valve. Oil level should be visible at the air vent valve hole

approx. 12mm below valve hole. Do not overfill. If low, add oil as needed then close air vent valve.

REPLACING OIL

For better performance & longevity, replace oil supply once a year. To drain oil, open Air Vent Valve and loosen the release Valve by

turning handle counter clockwise. BE VERY CAREFUL not to permit dirt or foreign matter to get into the system. Invert jack over

suitable container and allow oil to drain. Close release vale by turning handle clockwise, fill with SAE 10 Hydraulic Jack Oil close Air

Vent Valve wipe away any split fluid. Test jack before lifting a load.

CLEANING

Jack should be wiped clean with soft cloth only. Do not use gasoline, kerosene or other such solvents or any abrasive cleanser as

cleaning agents and solvents will cause deterioration of the hydraulic seals.

STORAGE

Before storage, twist handle 1-1/2 turns counter clockwise to release pressure in hydraulic cylinder. Leave handle in this position.

Store jack on a level surface, in clean environment preferably indoors in a dry area to protect jack from moisture.

REPARING JACK

There are no user serviceable parts except as outlined above. Only trained, licensed and certified repair personnel should attempt

any repairs or replacing parts. Any modifications to this jack, except those performed by the manufacturer, or their designee, will

void all warranties both written and implied.

a

a

PW TECHSAM Woch Sp. J. tel. 81 444-63-73

ul. Warszawska 131 tel. 81 443-08-12

20-824 Lublin fax 81 458-38-19

IMPORTER:

WARRANTY CONDITIONS

1. P.W. TECHSAM Woch Sp. J. with its registered office in Poland at Lublin, 131 Warszawska Av. guarantees the highest quality of

Quatros tools and workshop equipment. Warranty period for products is 12 months from purchase date excluding batteries being

part of tools for which warranty period is 6 months from purchase date.

2. This warranty does not apply to normal wear and tear of spare parts or any damage caused by improper maintenance (including

overloading of tool, using power tools with hand-operated tools, inefficient thread greasing etc.).

3. Complaint shall be filed at place where the tool was bought.

4. Faulty tool or equipment is repaired or replaced in 14 days from date of its receive unless additional expertise written by

manufacturer or expert is needed or replaced tool/part has to be delivered from manufacturer or unexpected occurrence like flood,

conflagration, strike, natural disease, embargo, break in production etc. takes place.

5. In case of sets warranty is limited to repair or replacement only complained part of the set, not whole set.

6. Due to specific working conditions this warranty does not apply to:

-hand-operated bits and socket bits, power bits and power socket bits,

-screwdrivers if type of damage is caused by using with inappropriate screw size or overloading.

Lublin, 01.07.2021

DECLARATION OF CONFORMITY

PW TECHSAM WOCH SP. J.

Al. Warszawska 131

20-824 Lublin

We hereby declare that:

Hydraulic Trolley Jack Low Profile, Dual Pump 3T

QUATROS QS19134

Is conformal to 2006/42/EC directive and fulfils requirements of following standards:

EN ISO 12100:2010, EN 349:1993+A1:2008, EN ISO 14120:2015, EN ISO 13857:2008

Is identical to product which is subject to EC type examination by:

Ente Certificazione Macchine Srl

Via Mincio, 386/a

41056 Savignano s./P. (MO) –ITALY

tel +39 059 763736

fax +39 059 766306

e-mail: [email protected]

Certificate no. 0B190320.JOMQ062

In case of unauthorized modifications to the product this declaration becomes invalid.

Person authorized to compile the technical file:

Marcin Puderecki

(Name)

Table of contents