- 8 -

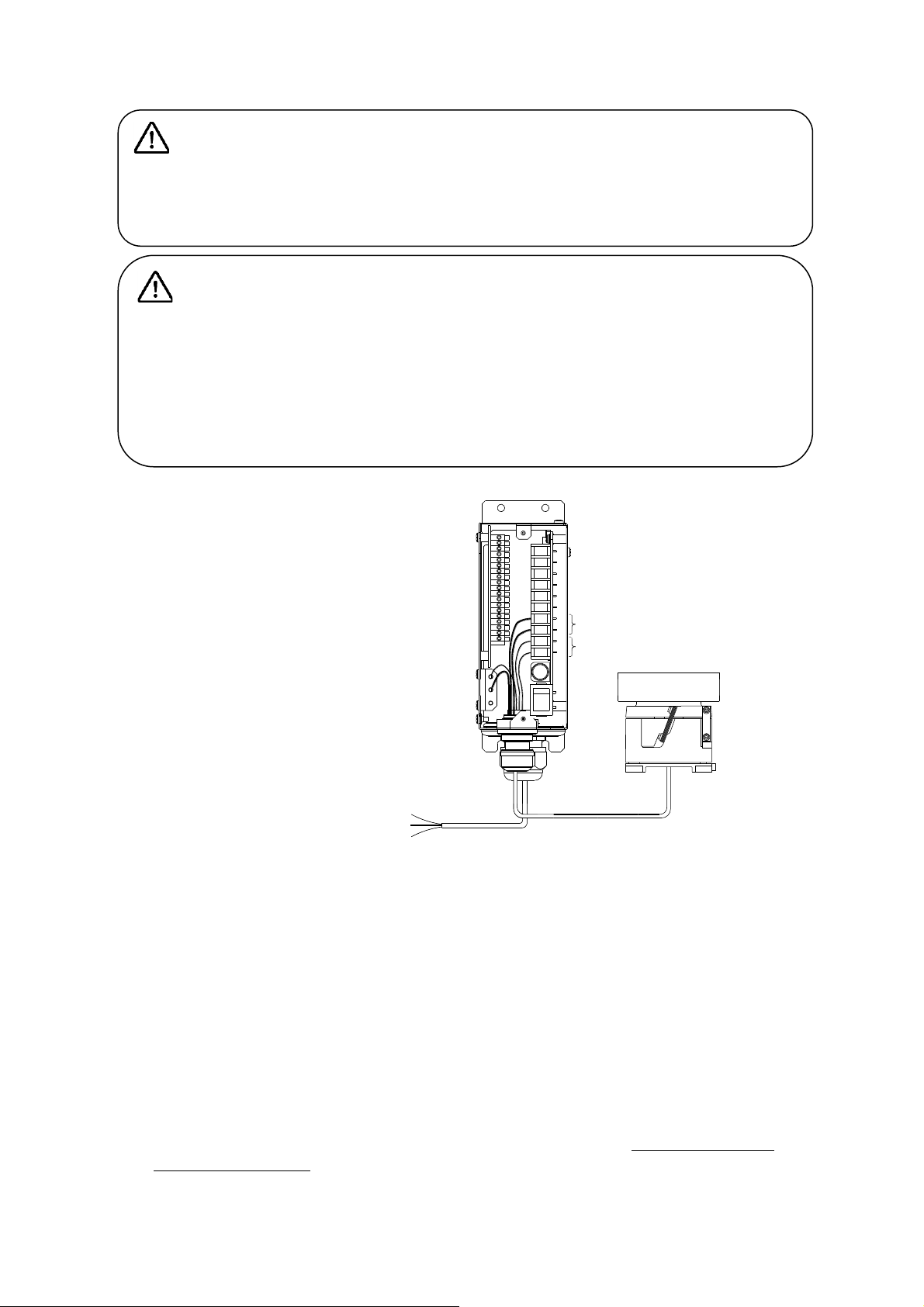

(Note 1) When the bowl feeder is used in assembly with another device or the like, do not turn On-Off

the “On-Off”switch on the primary side of the controller but make use of the external control

signal input terminal.

(Note 2) Ensure that the power connection work is executed by electrical engineers. When

modification or change of wiring is intended, be sure to refer to the Instruction Manual for the

bowl feeder controller.

(Note 3) Where a bowl is provided with an alignment mechanism and an instruction mark is located

around the speed control knob of the controller, operate the machine with the speed control

knob position adjusted to the marking.

(Note 4) When extension of the load cable is intended by your company, ensure the extension length of

10 m max. in use of a cable of 2.5 mm2min. in size. In addition, conduct the protective

continuity test to check that the machine is grounded appropriately.

(Note 5) For details of required operation of the controller to be used, refer to the Instruction Manual

for the bowl feeder controller.

8. Inspection and Adjustment

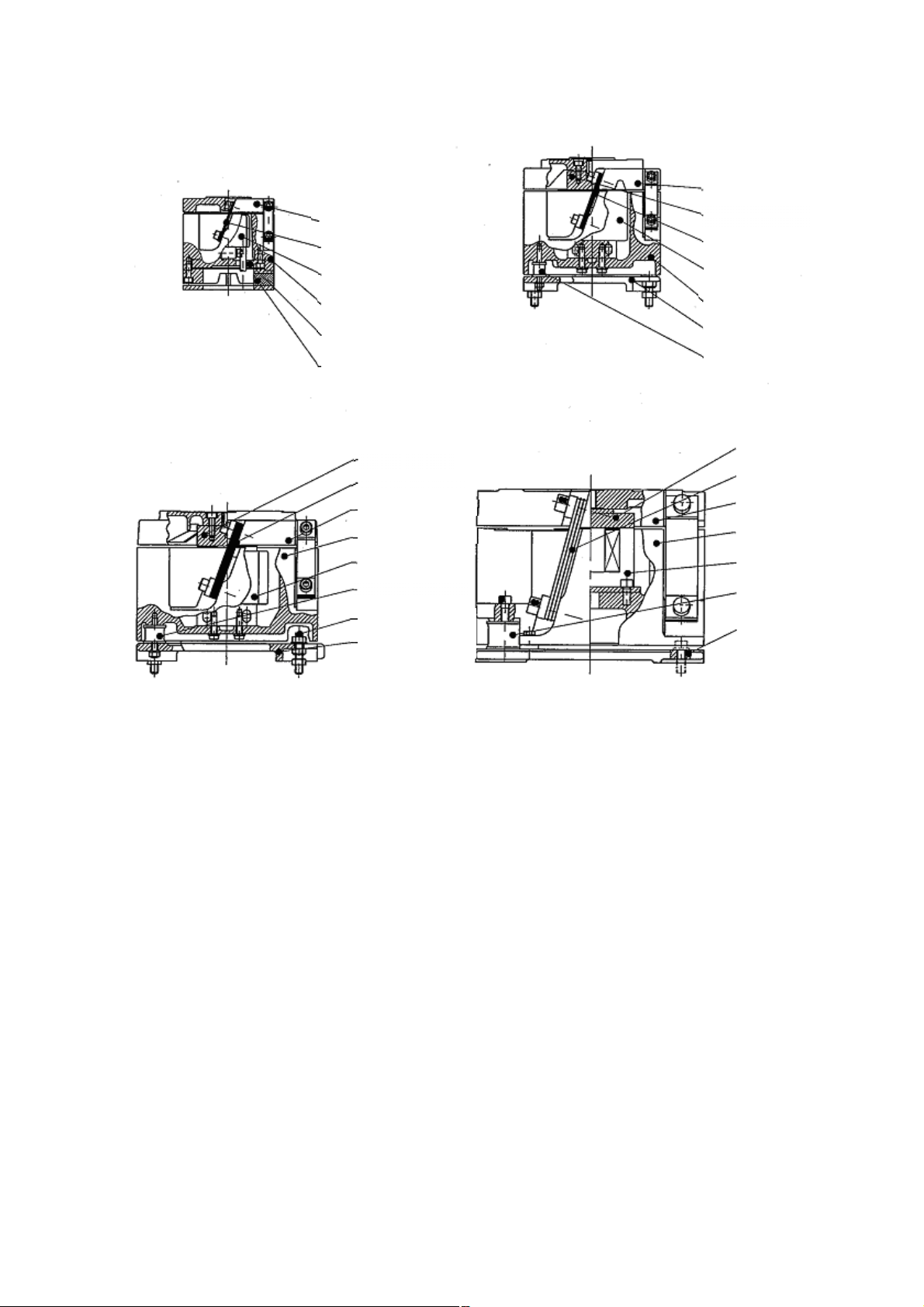

(1) Inspection and adjustment of leaf spring

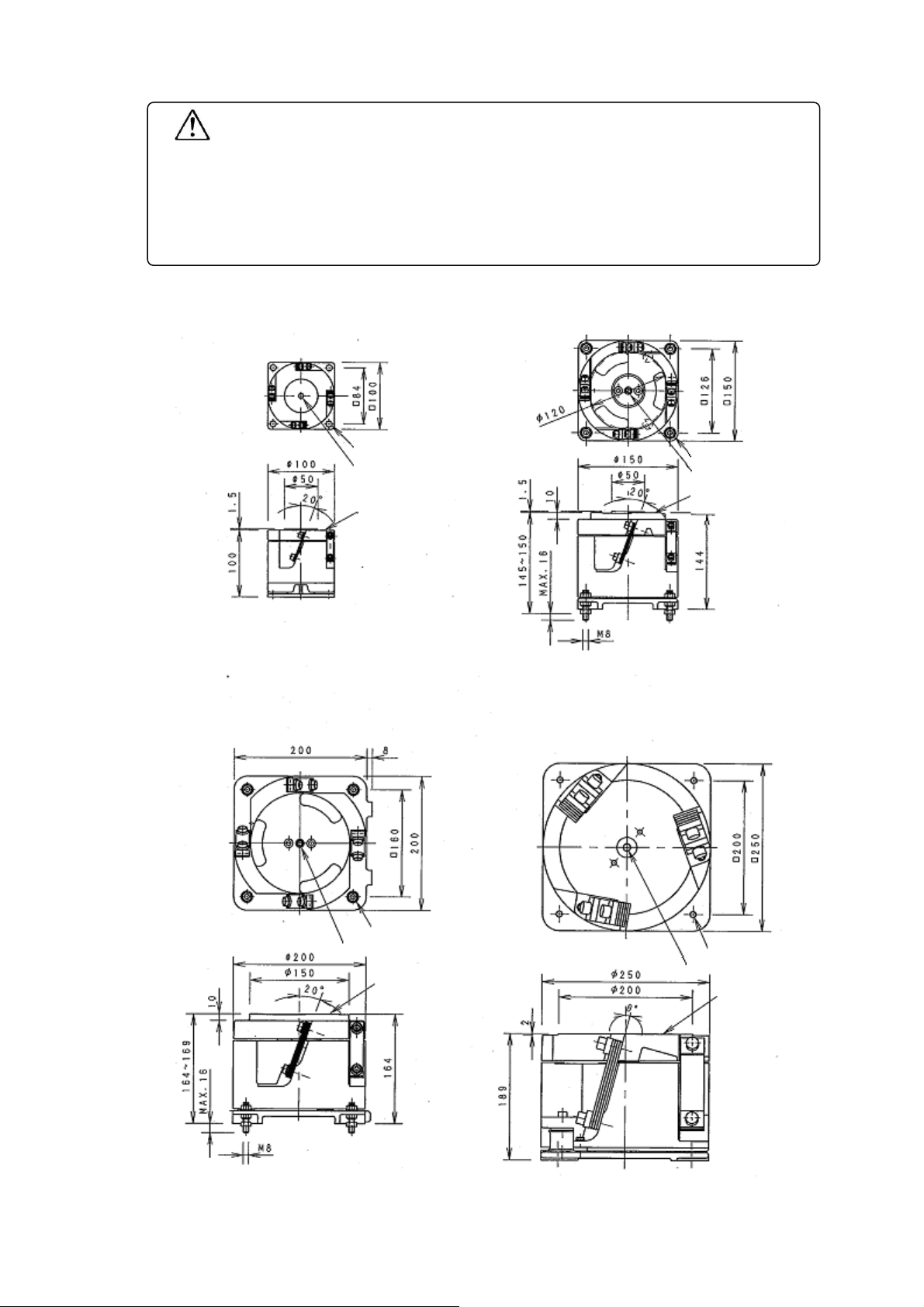

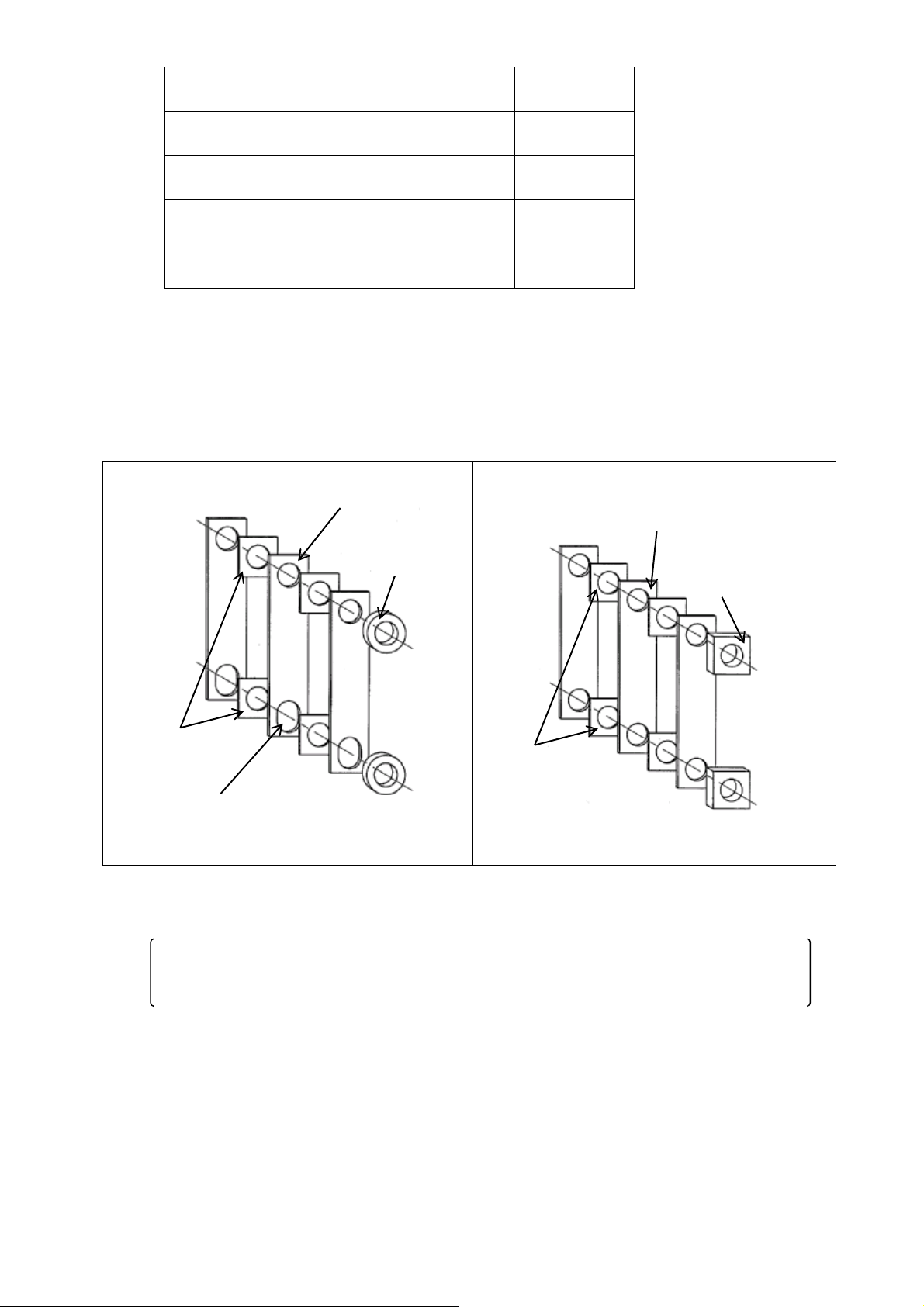

[1] Acceptable maximum amplitude of leaf spring

To prevent break of the leaf springs, operate the machine at amplitude lower than shown in the

following table.

If the machine should be operated at higher amplitude, the leaf springs may break at an early date.

When measuring the amplitude, be sure to attach the supplied amplitude marks as shown below

and total the readings of upper and lower amplitudes.

Amplitude

(upper area + lower area)

0.6 mm

1.1 mm

1.3 mm

(Note) When a recommended speed is designated by

NTN

, adjust the volume position to the

recommended scale.

[2] Caution in attaching and detaching leaf spring

When attaching and detaching the leaf spring, be sure to

complete one unit before moving to the next unit. Do not

loosen all the units at the same time.

a) Change the bolt length according to the increase or

decrease in the number of springs on assumption that

required bolt bite length (Dimension L includes the

dimension on the upper vibrator side) is at least 2 times

as large as screw diameter (at least 8 mm for K10).

Tighten bolts securely while referring to the tightening

torques shown below as standard values.

(upper vibrator)

(lower vibrator)