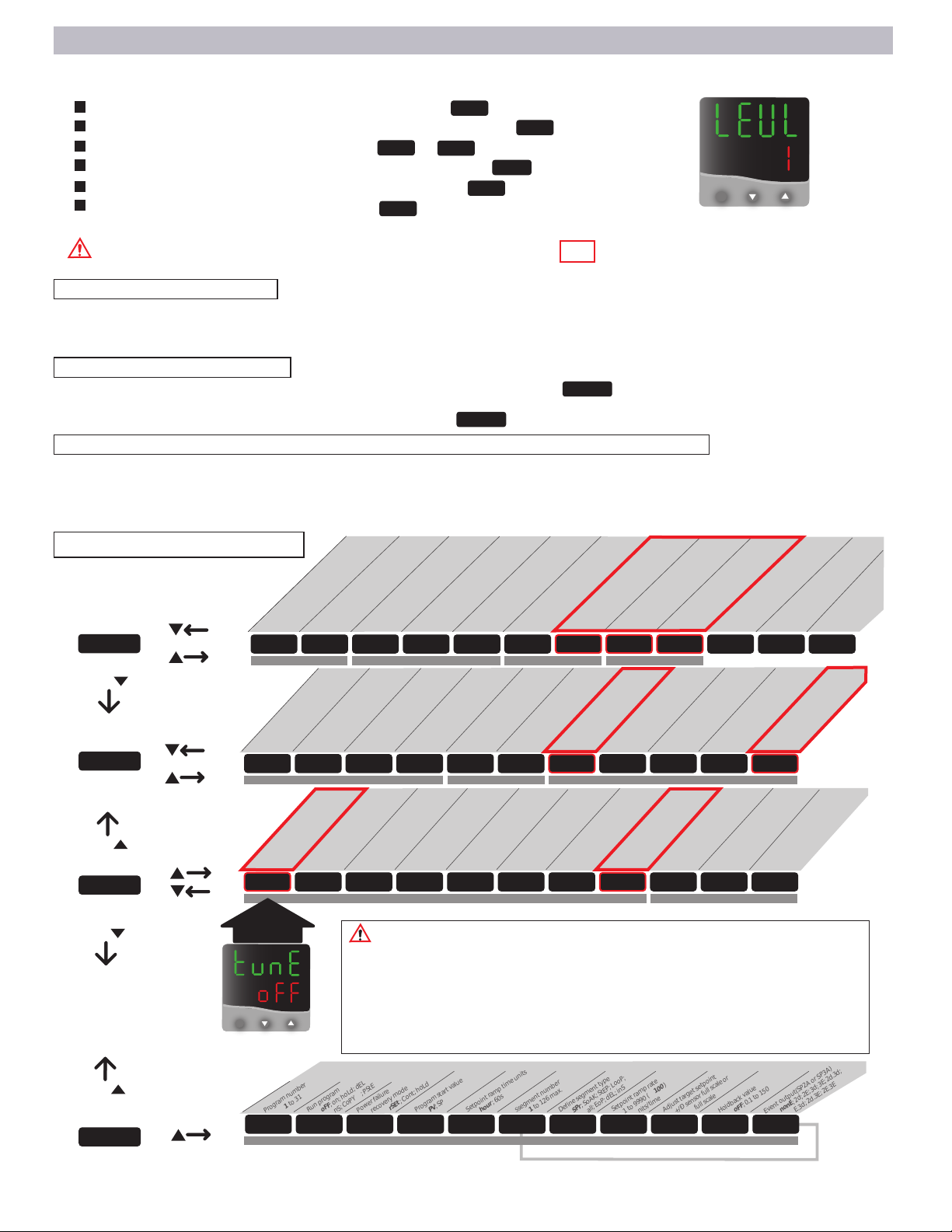

Menu Level Functions

*

(PRESS)

(PRESS)

*

(PRESS)

(PRESS)

(PRESS)

Functions Menu Guide

IMPORTANT NOTE

The non-high-lighted control functions within the menu levels are factory

set for the basic and safe operation of your model oven. Care should be

taken when navigating or changing user-applicable settings, outlined

in red, so as not to alter these factory settings. Factory settings for each

function are listed within the parentheses "( )" in each function tab above -

use only as a trouble-shooting reference.

To access the menu levels:

Press and hold both arrow keys until the "tune" / "off" function prompt is displayed from within LEVEL 1. When in the

function menu the LED display will alternate the function prompt with the current function setting when keys are

released. See "menu entry point" in Menu Guide below.

To navigate within the menu:

Press the down arrow to move "Left" into menu LEVEL SELECTION ( level 1) (FIG ). Use up and down arrow

keys individually to move "right" or "left" within a level. Hold star key and up or down arrow keys to move "up" or

"down" through levels 1, 2 and 3.(Note: you must be at prompt to move up/down thru levels)

To change the function setting (or to read function data - if a read only function):

Once at the desired level function prompt, press and hold the star key and press the up or down arrow key to change

a function setting or to read alternate function data. Release star key to set the function. Press and hold the up and

down keys together to return to temperature display, or control will auto-return in 60 seconds.

FUNCTION PROMPT

CHEK

SP.LK

\\

UNIT

ZERO

READ

DISP

LEVL 1

LEVL 1

SP1.D SP2.D BURN REU.D REU.L SPAN ZERO CHEK READ TECH UER RSET

LEVL 3

RELAY OUTPUT TYPE SAFETY SETTINGS CONTROL CALIBRATION TEMPERATURE TRACKING

\\

SP1.P HAND PL.1 PL.2 SP2.A SP2.B DISP HI.SC LO.SC INPT UNIT

LEVL 2

MANUAL ADJUSTMENTS AUDIBLE/ALARM MODES RESOLUTION, RANGING, INPUT AND UNIT SELECTION

TUNE BAND INT.T DER.T DAC CYC.T OFST SP.LK SET.2 BND.2 CYC.2

LEVL 1

PID AND PERFORMANCE SETTINGS SP2 AUDIBLE / ALARM SETTINGS

Program number

1to 31

Run program

oFF; on; hoLd; dEL

inS; CoPY ; PStE

Power failure

recovery mode

rSEt ; Cont; hoLd

Program start value

PV; SP

Setpoint ramp time units

hour; 60s

Holdback value

oFF; 0.1 to 150

Event output(SP2A or SP3A)

nonE;2d;2E;3d;3E;2d.3d;

2E.3d; 2d.3E; 2E.3E

PROG RUN FAIL ST.U SPRU SEG TYPE SPRR T.SP HB.V EO.P

LEVL P RAMP & SOAK PROGRAM SETTINGS

S

segment number

1to 126 max.

Define segment type

SPr;SoAK;StEP; LooP;

Call;EoP;dEL;inS

Setpoint ramp rate

1 to 9990 ( 100)

units/time

Adjust target setpoint

+/Ðsensorfullscaleor

full scale

Press star key & up

or down arrow key

to scroll through

functions levels

Press up & down

arrow keys to

scroll back-and-

forth through

level functions

Level "P" is the Ramp

& Soak program level.

See separate Ramp &

Soak Programming

Operating Manual

*

(PRESS)

*

Sensor burn-out

(uP.SC),dn.sc,1u.2d,1d.2u

Reverse outputs

(1r.2d ), 1d.2d,1r.2r, 1d.2r

Reverse outputsLEDs

(1n.2n ), 1i.2n, 1n.2i,1i.2i

Primary Relay Output (heater)

none, rly,(ssd), AnLG

Secondary Relay Output (signal)

none, rly,(ssd), AnLG

Advanced Auto TuneData

(read only / see mfgsmanual)

SoftwareVersion

(read only)

Setpoint Lock Function

(oFF),on

Auto TuneFunction

(oFF),on,PArk,At,SP

DerivativeApproach

Control

(5.0), 0.5 to 5.0

DerivativeTime(rate)

off, or 0.1 to 200 seconds

(25)or auto-tune variation

Integral Time(reset)

off, or 0.1 to 60 minutes

(5.0) or auto-tune variation

Proportional Band

0.1 to 100%of sensor max

(17)or auto-tune variation

Offset (manual reset)

(0), 0 to50%x band

Int.t = off

Cycle Timeor on/off

on.of, or 0.1 to 81 seconds

(20)

Control Reset

(Do Not Reset)

Set SP2 output %

(100)%to 0%

Limit heater output %

(100)%to 0%

Read heater output %

varies100%to 0%

read only

Set SP1 manual output

"heater" (off), 100%to 0%

Select oC/ oF

NONE,oC, (oF),Bar,PSi, Ph

ThermocoupleType

none, (J), k,l,r,s

,t, rtd

Set Temperaturemin scale

(50) F

Display Resolution

(1) or 0.1 degree

SP2 Cycle on/off

(on.of), or 0.1 to 81

SP2 Band / Gain / Hyst.

(0.2) 0.1 to 100%

of sensor full scale

Adjust alarm set point if

SP2 configured as alarm

(0) , 1 to full scale

ConfigureSecond mode

(none), LtCH,hold,Lt.ho

Configuremain mode

(EOP), none, dV.hi,..FS.hi,..

Set Temperature max scale

(325,450,550)Fper model

TemperatureTracking Monitor

on ,(Off)

Read Tracking Monitor Results

VAr , hi , Lo (read only)

Sensor Span Adjustment

(0.0) to 25%of sensor'sfull scale

Control Calibration Adjust

varies: (-3.0 to 3.0)

TUNE *

MENU ENTRY

POINT

*

All user-applicable functions and their menu locations are outlined in red in Menu Guide below

Access the menu levels for the following functions:

Change control to read in C or F temperature units ( in level 2).

Change to whole degree or 1/10th degree display resolution ( in level 2).

Run or Read temperature tracking /data ( or in level 3).

Lock Temperature setting against inadvertent adjustment ( in level 1).

Calibrate control temperature to an external standard ( in level 3).

Auto Tune PID performance parameters ( in level 1).

PAGE 6

FIG. 7