Read Operating Instructions Thoroughly Prior to Operation

Safety Precautions

PAGE 4

Shelf Installation and Use

General Operation

For ease of temperature setting and pin-point temperature accuracy over the full temperature range,

contact dealer or factory for a field-installable upgrade control package with digital microprocessor

temperature controller with dual LED display (or see our ER models).

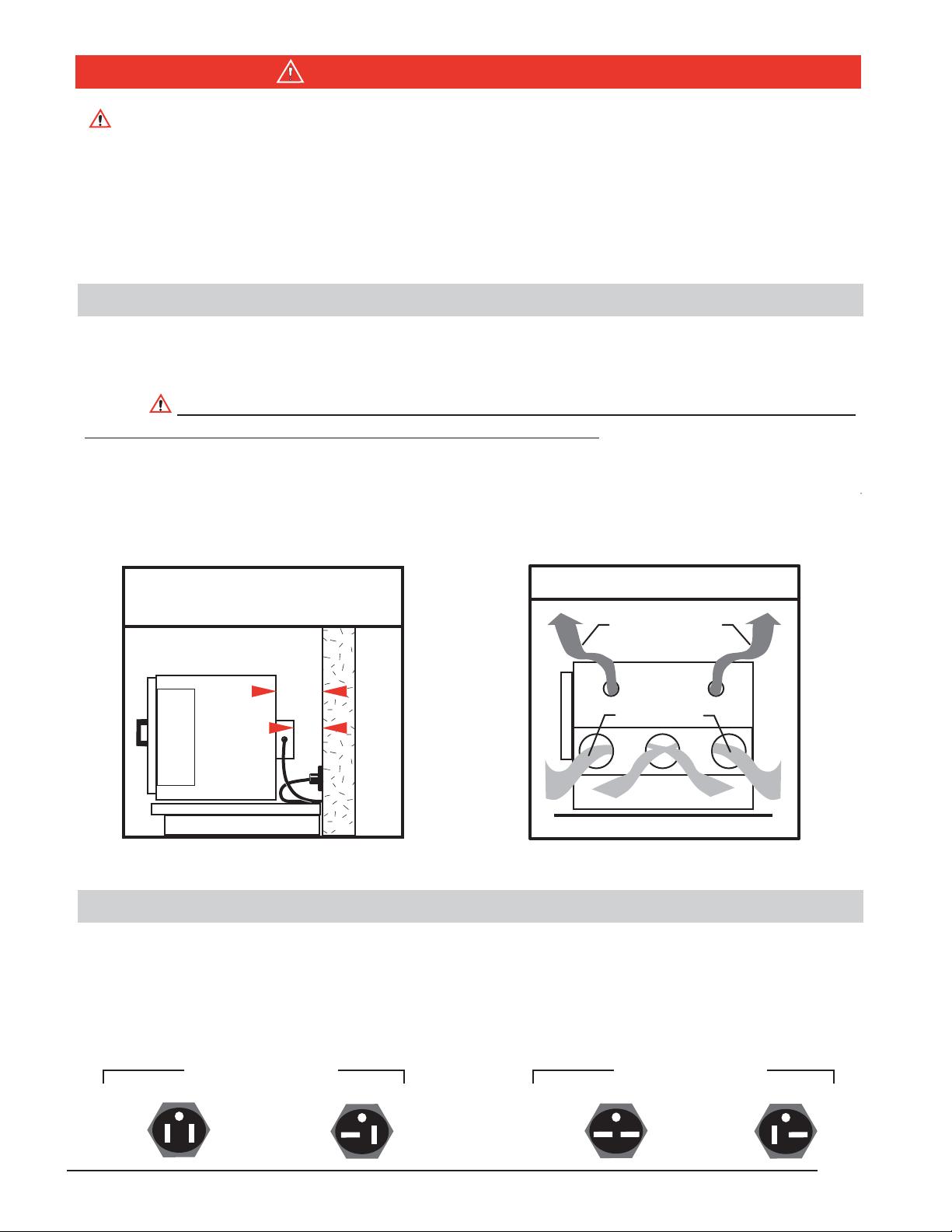

FIG. 4

Install adjustable shelf by first placing the shelf bracket rivets into the corresponding keyhole

supports located on each inner side of the oven. Orientate the bracket in the "down" or " L" position.

This position guides the shelf in and out and protects the side wall from being scratched. The bracket

may also be placed in the "up" or " " position if

slightly more interior clearance is needed. Place

the shelf on the brackets as shown. (FIG. 4)

Each shelf will support a distributed load of 100

lbs. maximum. Do not exceed a combined total

of 300 lbs. within the oven at one time.

Avoid

placing articles on the oven floor. Instead, use a

shelf at the lowest adjustable position.

Care should be taken when removing articles

from the oven. Don't pull the shelf out when

removing heavy loads. The shelf is not secured

and loads can tip and fall forward.

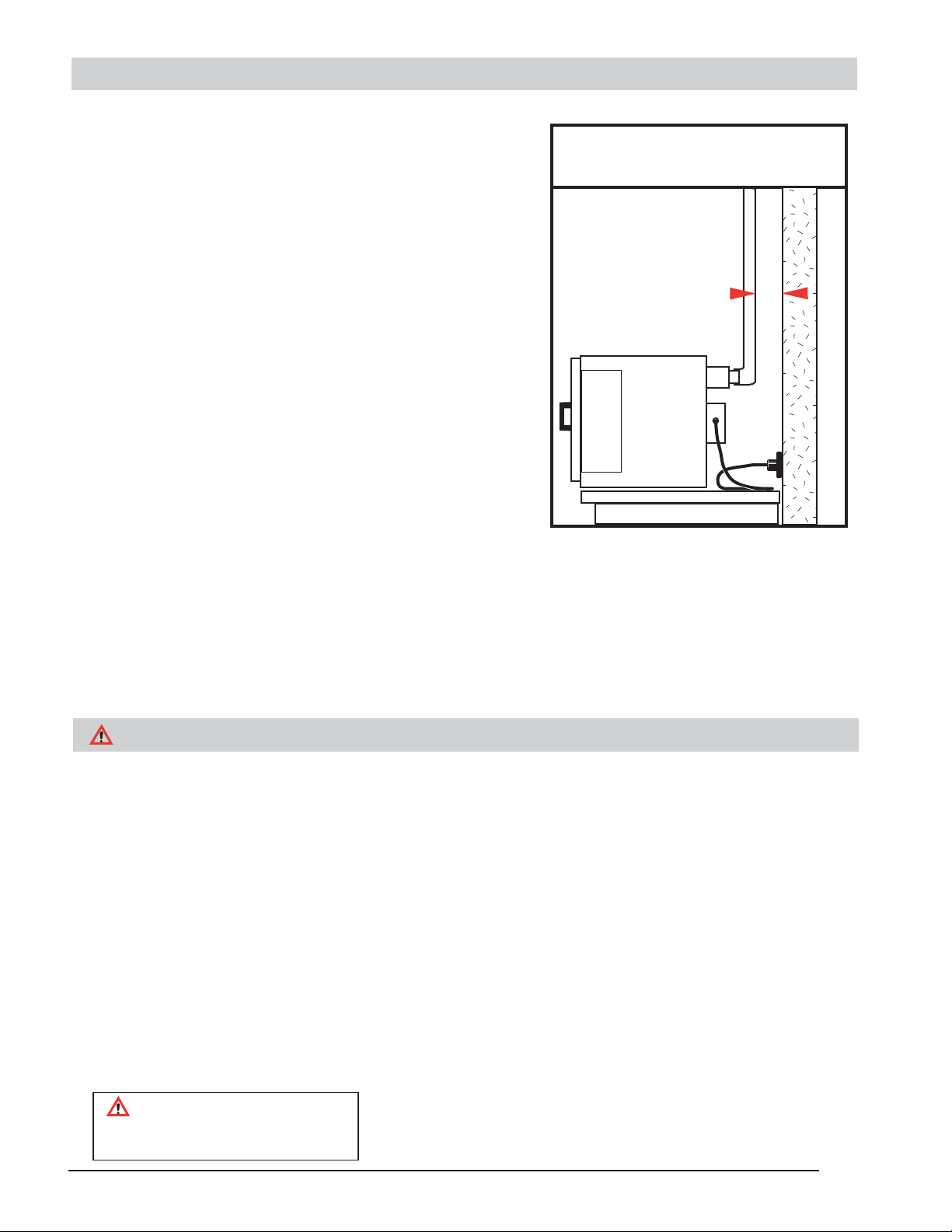

Turn the power/recirc. fan switch to the up position. Turn heater switch to heat. Rotate the

thermostat dial to the desired temperature. The heat cycle light will illuminate until the set

temperature is reached. Once reached, the heat cycle light will cycle on and off with the heaters,

maintaining the set temperature. Typically, the oven will need to cycle at a set temperature for a

minimum of 20 minutes before it will achieve equilibrium and becomes stable (see stability specs.

on page 1).

The heater switch in the off or cool position allows for convenient ambient air drying of articles or to

help slowly or evenly cool heated articles without having to lower or change the temperature

setting. Also, use this switch to allow the oven to cool before turning the fan off when using the oven

at higher temperature settings. This helps to both cool the motor (prolonging it's life), and remove

moisture-laden air before it condenses in the chamber, which will help prevent premature corrosion

over time.

Note: The temperatures printed on the dial are designed to help quickly set a temperature to within

a close proximity of the indicated dial temperature. Small rotational adjustments to the dial will

likely be required to set a more precise temperature setting as measured against a reading from a

glass-type or door-mounted dial thermometer (optional) or other external measurement device

(insert thermometer or probe in small port hole located on the top right-front corner). Also, any

degree of offset observed for a given temperature setting may be different for other temperature

settings on the dial.

The control dial is calibrated at the factory in the middle of the model's

temperature range and is therefore most accurate in these middle range temperatures

(some oven

model's knob/dial may have printed temperature markings that are higher than the model's actual

maximum range).

Over time, continuous use at a single temperature setting may require periodic re-adjustment as the

contacts wear or as ambient temperatures change seasonally or from air conditioning or heating

(see also control calibration page 5).