2

Introduction……………………………………………......2

Important Safety Precautions .....................................2

Decisions You Must Make............................................3

Engine Selection.............................................................3

Radio Equipment ...........................................................3

Additional Items Required...........................................3

Building Supplies and Tools...........................................3

Kit Contents .................................................................3

Wing Build……..............................................................4

Horizontal Stabilizer, Elevator and Rudder................6

Aileron Build………………………………………………7

Fuselage Build……………………………………….……8

Final Assembly ............................................................9

Motor Installation………………………………………....9

Radio Installation………………………………………....9

Balance Your Model.....................................................11

Balance Your Model Laterally.....................................11

Battery Installation.......................................................11

Remember: Take your time and follow the instructions

to end up with a well-built model that is straight and

true.

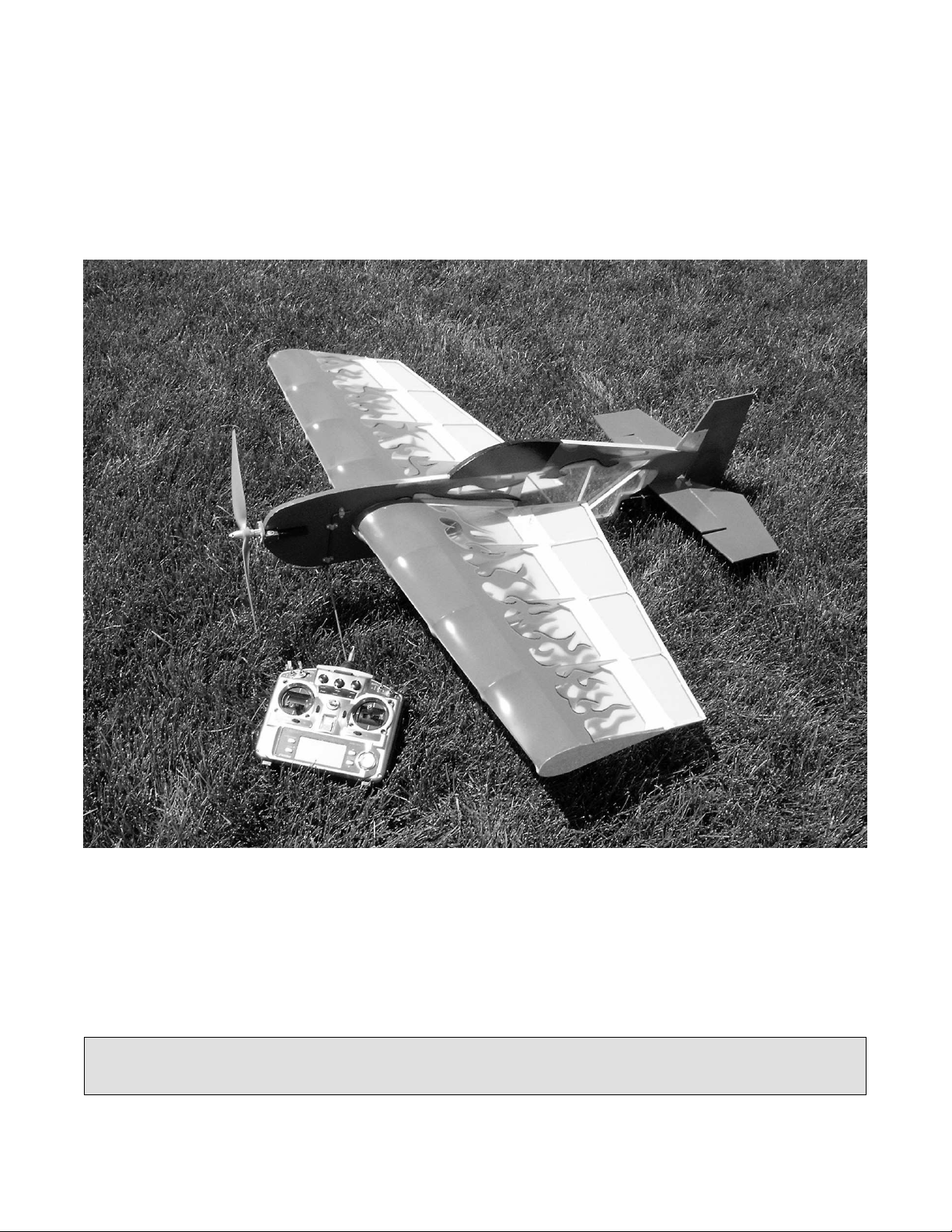

If you have not flown this type of model before, we

recommend that you get the assistance of an experienced

pilot for your first flights. If you're not a member of a club,

your local hobby shop has information about clubs in your

area whose membership includes experienced pilots.

In addition to joining an R/C club, we strongly recommend

you join the The Profilebrotherhood (ProBro). ProBro

membership gets you access to thousands of skilled and

talented 3D pilots that will not give you BS, politically

correct answers. They will teach you how to set up your

plane properly, and turn you into a great 3D pilot.

Join here:

The Profile Brotherhood

http://www.theprofilebrotherhood.com

1. This airplane should not be considered a toy, but

rather a sophisticated, working model that functions very

much like a full-size airplane. Because of its performance

capabilities, this plane, if not assembled and operated

correctly, could possibly cause injury to yourself or spectators

and damage property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as doing so

may result in an unsafe or unflyable model. In a few cases the

instructions may differ slightly from the photos. In those

instances the written instructions should be considered correct.

3. You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in first-class

condition, and a correctly sized engine and components

(battery, wheels, etc.) throughout the building process.

5. You must properly install all R/C and other components so

that the model operates properly on the ground and in the air.

6. You must check the operation of the model before every

flight to insure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

clevises or other connectors often and replace them if they

show any signs of wear or fatigue.

7. If you are not already an experienced R/C pilot, you

should fly the model only with the help of a competent,

experienced R/C pilot.

8. While this kit has been flight tested to exceed normal use,

if the plane will be used for extremely high stress flying, such

as racing, the modeler is responsible for taking steps to

reinforce the high stress points.

Table of Contents

Introduction

Protect your model, yourself and

others. Follow these important safety

precautions!

Note: I, as the kit manufacturer, we strive provide you with a top

quality kit and instructions, but ultimately the quality and

flyability of your finished model depends on how you build it.

COPYRIGHT © 2005

Quinn Coldiron

qcoldir@yahoo.com