INTRODUCTION

SCOPE

This manual

contains

information describing the

operation and maintenance

of

the QumeTrak 542

Flexible Disk Drive. The first section

of

the manual

describes

the

design

features

and

the

configuration

specifications.

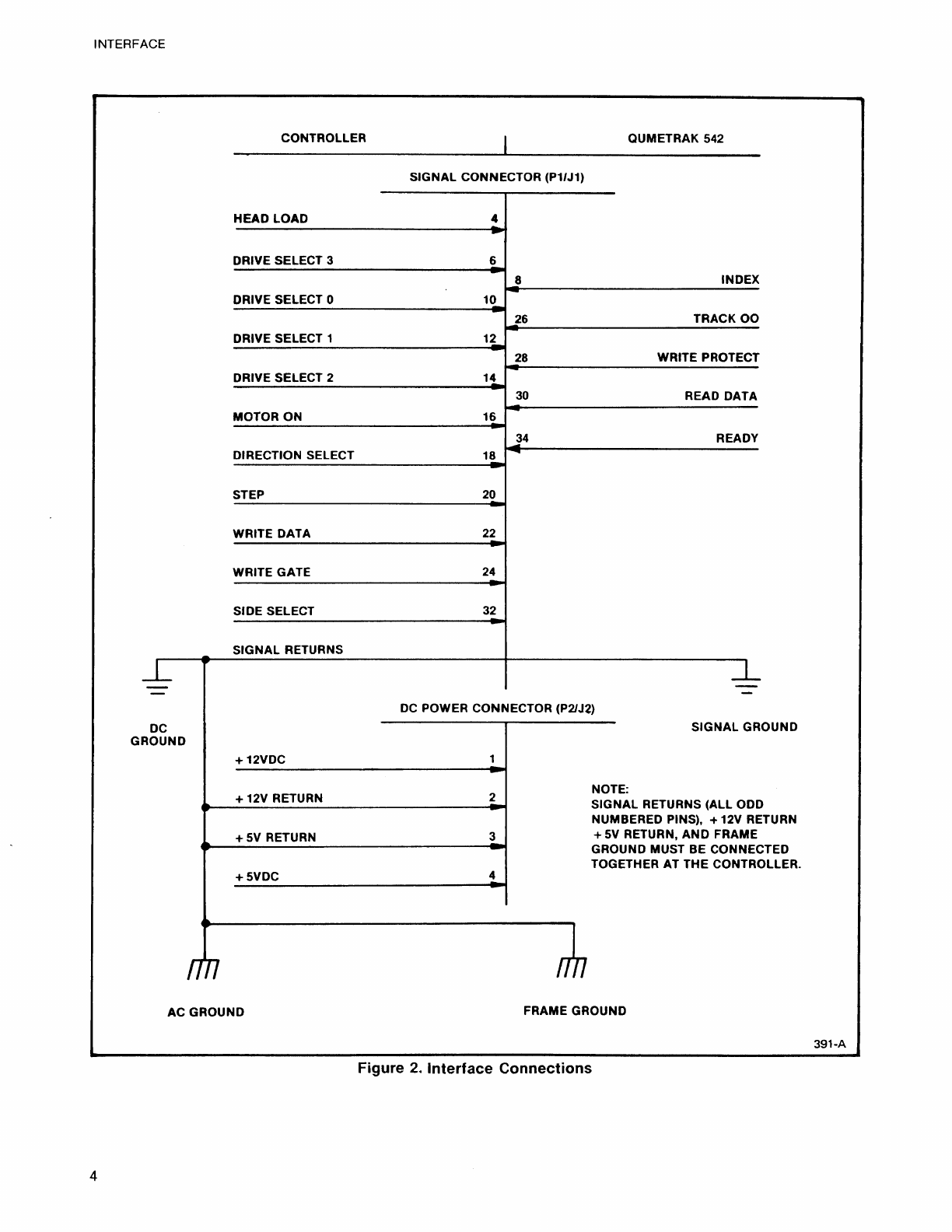

The INTERFACE

section

lists

the physical connections

of

the

QumeTrak

542

and describes

the

electrical

interface

lines. The INSTALLATION

section

provides inspection, unpacking, and mounting

information.

The CUSTOMER STRAPPABLE

OPTIONS

section

describes

the

available

strappable

options

and possible configuration

modifications.

The

MAINTENANCE

section

provides preventive

maintenance

information,

removal and replacement procedures, adjustment

instructions,

diagnostics

and

troubleshooting

procedures.

DESCRIPTION-

GENERAL

The QumeTrak 542 Flexible Disk Drive is alow

cost

direct access data storage device for

5.25

inch,

two-sided

flexible (floppy) diskettes. It

is

an

advanced and sophisticated design

that

is based

on Qume's years

of

manufacturing experience

with

the larger QumeTrak 842

eight-inch

version. The

QumeTrak

542

employs a

two-sided

head carriage

assembly with aceramic Read/Write

(R/W)

head for

long media life. It also uses afield-proven, lead

screw system for

highly

accurate and reliable head

positioning. The media drive is a

DC

spindle drive

motor. This eliminates

the

need for AC power

to

the unit. The QumeTrak 542 is also equipped

with

a

door interlock

which

ensures

that

the

door does

not close unless

the

diskette

is properly inserted.

The QumeTrak

542

weighs

only

three pounds (1.4

kg) and can be mounted three drives horizontally,

or

four drives vertically in astandard

19-inch

rack

and panel unit. Refer

to

the INSTALLATION

section for additional information.

Standard Features on

the

QumeTrak 542 include:

Low heat dissipation

Four drive daisy chain

capability

Internal write protect

circuitry

In

Use LED activity

indicator

on the front panel

The QumeTrak

542

has interface

compatibility

with

the Shugart SA450 disk drive, and

complies

with

the American National Standards

Institute

(ANSI)

interface

specifications

for 5.25 inch flexible

disk

drives.

PERFORMANCE SPECIFICATIONS

The QumeT-rak 542 provides aformatted storage

capacity

of

143.4K bytes on a

two-sided

single

density flexible diskette, and 286.7K bytes on a

two-sided

double density flexible diskette. Refer

to the table below for additional performance

specifications: