CONTENTS

1. INTENDED USE .................................................................................................................................................5

2. WARRANTY CONDITIONS ...............................................................................................................................5

3. MAINTENANCE..................................................................................................................................................5

4. SERVICE AND REPAIR.....................................................................................................................................6

5. RECYCLING.......................................................................................................................................................6

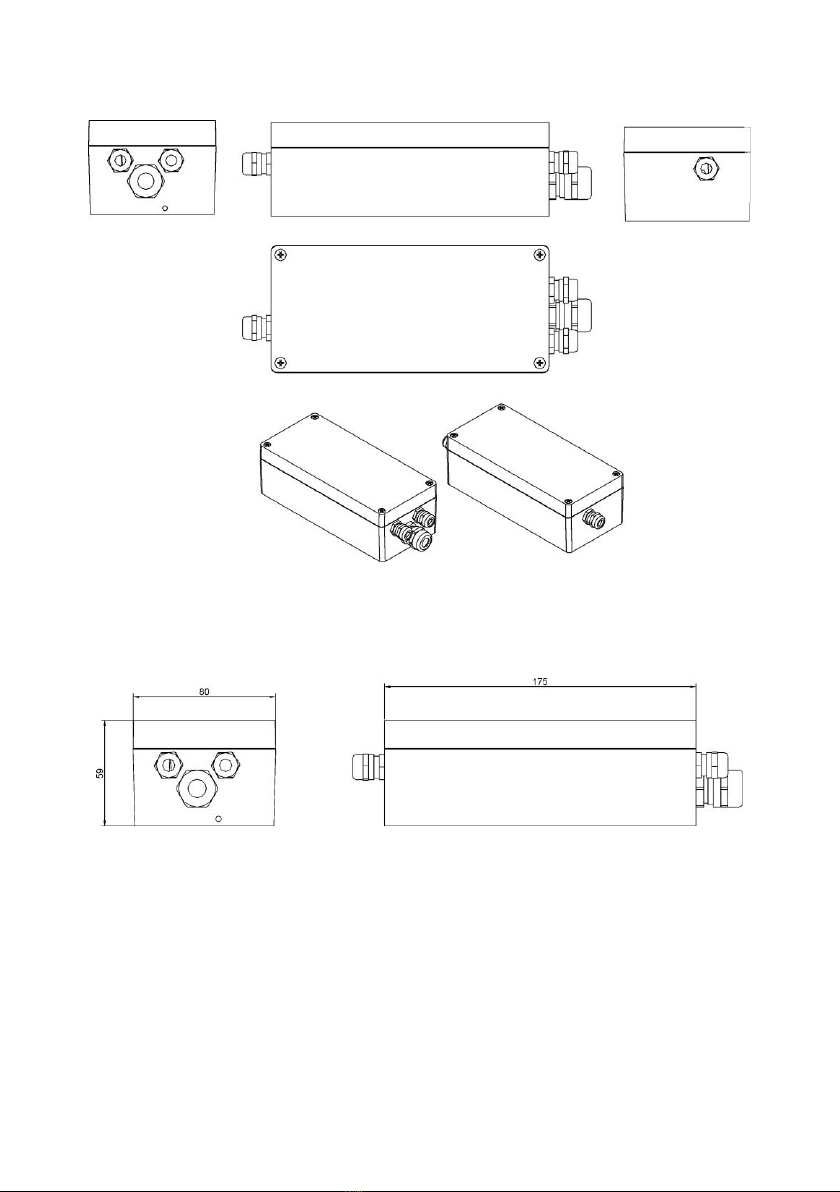

6. MECHANICAL DESIGN..................................................................................................................................... 6

6.1.General View................................................................................................................................................7

6.2.Dimensions...................................................................................................................................................7

6.3.Connectors...................................................................................................................................................7

6.3.1.RS232 Connector................................................................................................................................8

6.3.2.RS485 Connector................................................................................................................................8

6.3.3.Ethernet Connector .............................................................................................................................8

6.3.4.PROFIBUS Connector ........................................................................................................................8

6.4.Diagrams of Connection Cables..................................................................................................................9

6.5.Technical Specifications.............................................................................................................................10

6.5.1.IN/OUT Parameters...........................................................................................................................11

7. INSTALLATION................................................................................................................................................11

7.1.Unpacking and Installation.........................................................................................................................11

7.2.START-UP .................................................................................................................................................12

8. INSTALLER INSTRUCTION............................................................................................................................12

8.1.6-Wire Load Cell Connection.....................................................................................................................12

8.2.4-Wire Load Cell Connection.....................................................................................................................13

8.3.Connecting Load Cell’s Cable Shield.........................................................................................................14

9. FACTORY PARAMETERS ..............................................................................................................................14

9.1.Factory Parameter Access.........................................................................................................................14

9.2.Factory Parameters....................................................................................................................................15

9.3.Parameter Value Modification....................................................................................................................16

9.4.Factory Adjustment ....................................................................................................................................16

9.4.1.Start Mass Determination..................................................................................................................16

9.4.2.Adjustment Factor Determination......................................................................................................17

9.5.Gravitational Correction .............................................................................................................................17

9.6.Linearity Correction....................................................................................................................................18

10. ERROR MESSAGES .....................................................................................................................................19