CONTENTS

1. INTENDED USE .................................................................................................................................................5

2. WARRANTY CONDITIONS ...............................................................................................................................5

3. MAINTENANCE..................................................................................................................................................5

4. SERVICE AND REPAIR.....................................................................................................................................6

5. RECYCLING.......................................................................................................................................................6

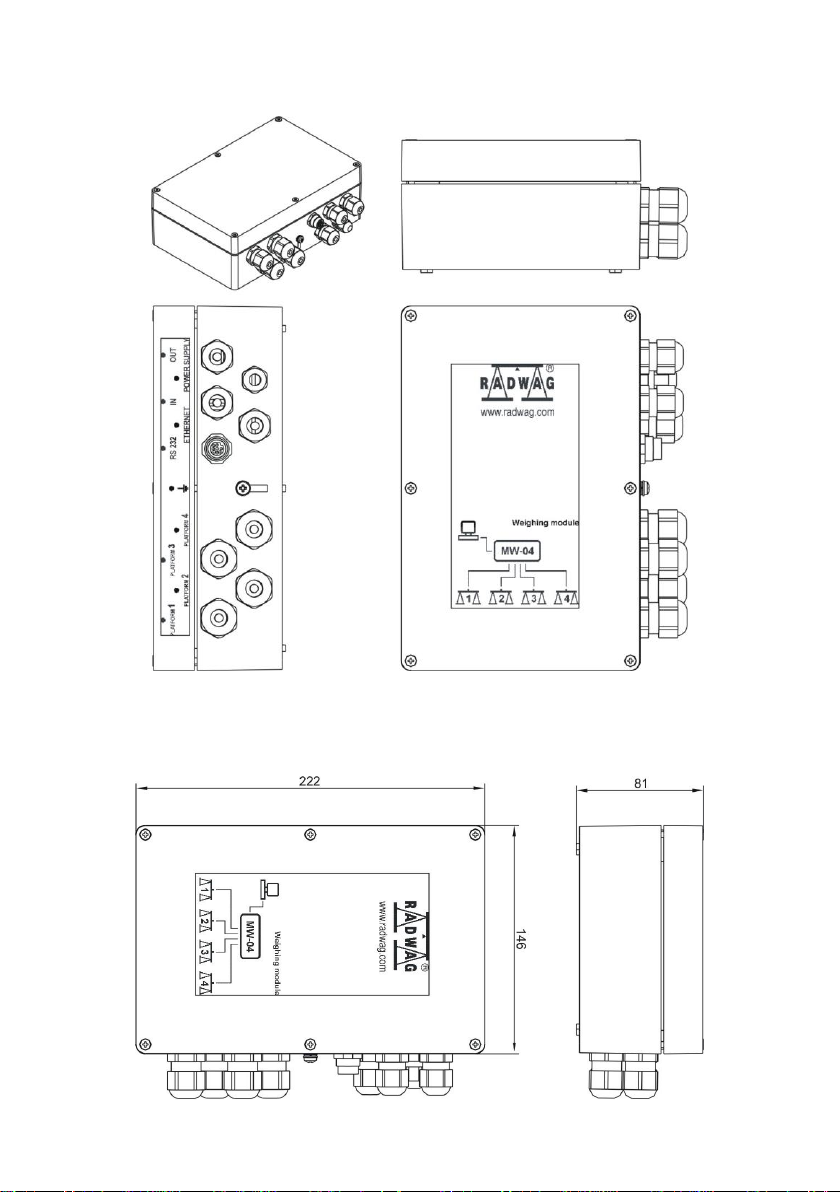

6. MECHANICAL DESIGN.....................................................................................................................................6

6.1.General View................................................................................................................................................7

6.2.Dimensions...................................................................................................................................................7

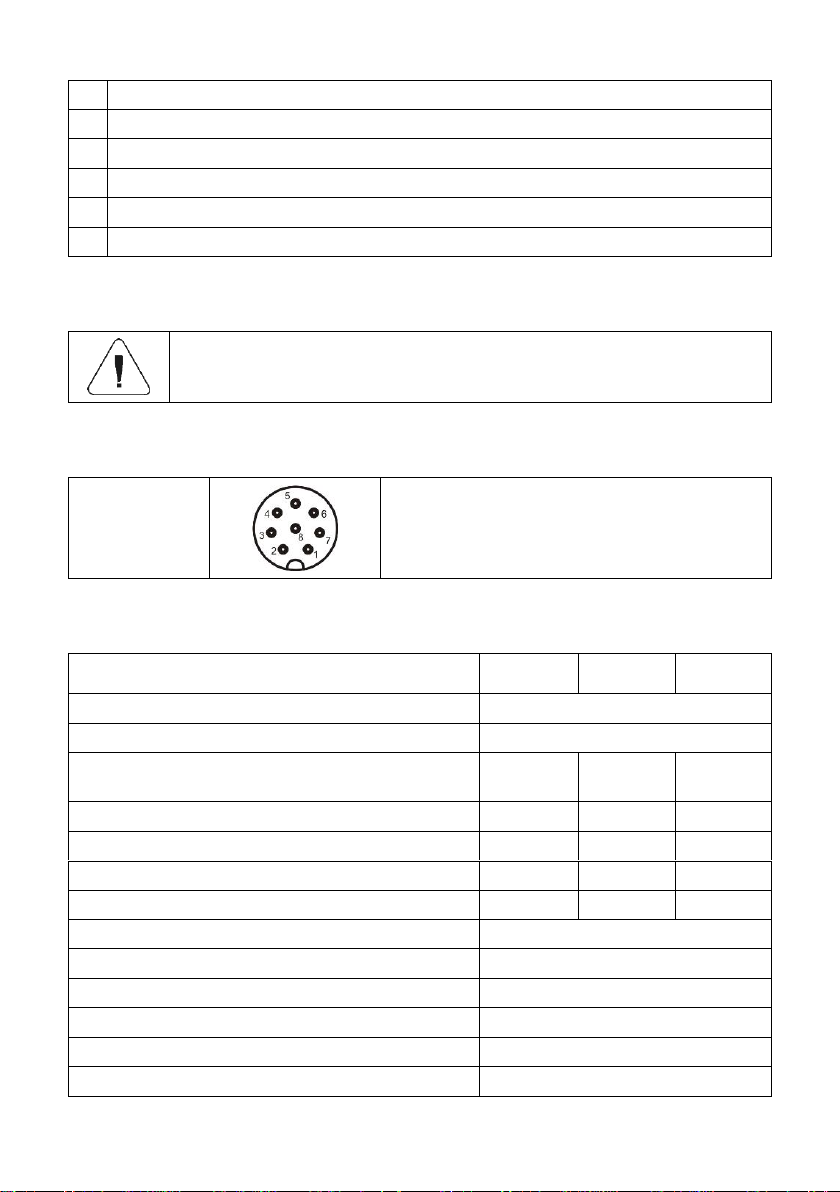

6.3.Connectors...................................................................................................................................................8

6.4.Pin Arrangement ..........................................................................................................................................9

6.4.1.RS232 Pins .......................................................................................................................................9

6.5.Technical Specifications...............................................................................................................................9

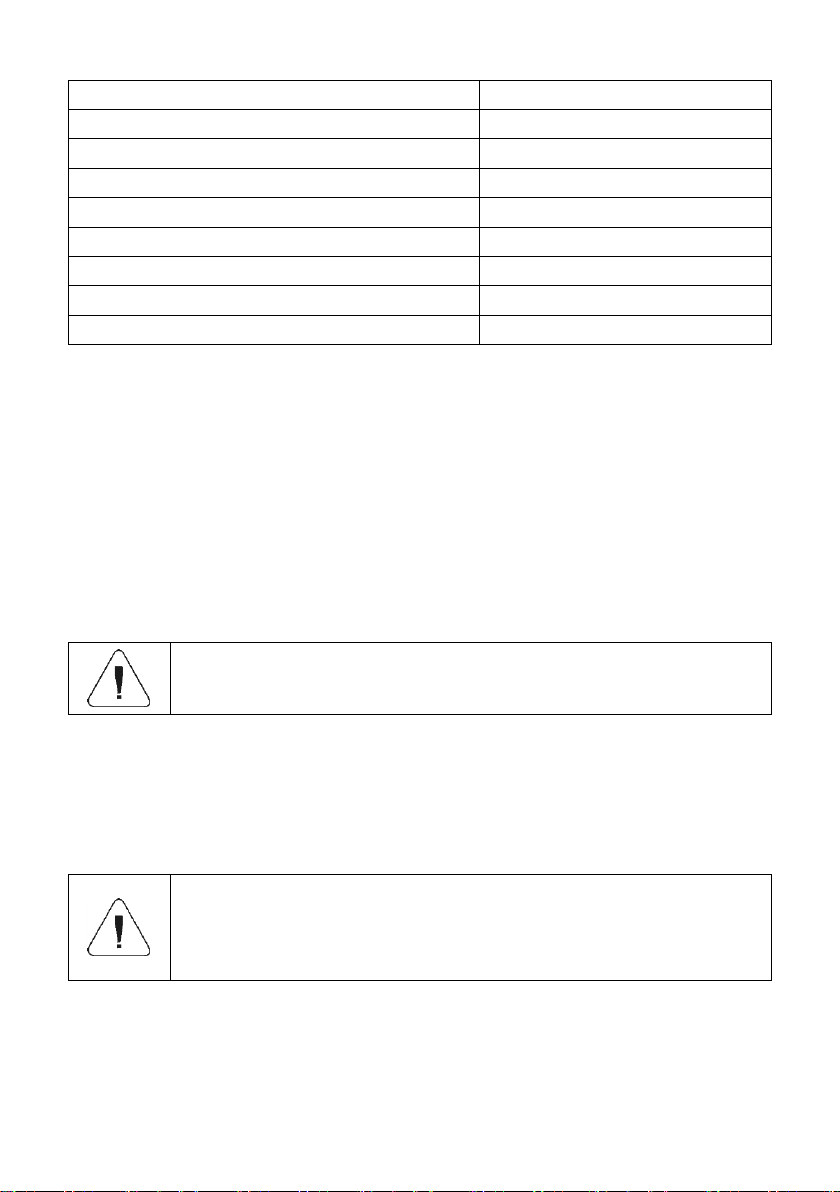

7. INSTALLATION................................................................................................................................................ 10

7.1.Unpacking and Installation.........................................................................................................................10

7.2.START-UP .................................................................................................................................................10

8. INSTALLER INSTRUCTION ............................................................................................................................11

8.1.6-Wire Load Cell Connection.....................................................................................................................11

8.2.4-Wire Load Cell Connection.....................................................................................................................12

8.3.Connecting Load Cell’s Cable Shield.........................................................................................................12

9. FACTORY PARAMETERS .............................................................................................................................. 13

9.1.Factory Parameter Access.........................................................................................................................13

9.2.Factory Parameters....................................................................................................................................14

9.3.Parameter Value Modification....................................................................................................................16

9.4.A/D Converter and Platform Configuration ................................................................................................16

9.5.Factory Adjustment ....................................................................................................................................16

9.5.1.Global Adjustment...........................................................................................................................16

9.5.2.Point Adjustment.............................................................................................................................17

9.5.3.Start Mass Determination................................................................................................................19

9.6.Gravitational Correction .............................................................................................................................20

9.7.Linearity Correction....................................................................................................................................20

10. EXTENSION MODULES................................................................................................................................21

10.1. 4IN//4OUT Module ...................................................................................................................................21

10.1.1. Technical Specifications...............................................................................................................21

10.1.2. Schematic Diagrams.....................................................................................................................22

10.1.3. Input / Output Signals ...................................................................................................................22

10.2. RS485 Module .........................................................................................................................................23

10.2.1. Signal Layout ................................................................................................................................23

10.2.2. RS485 Cable.................................................................................................................................23

10.3. PROFIBUS Module..................................................................................................................................23

10.3.1. Pin Arrangement...........................................................................................................................24

10.3.2. Interfaces Board with PROFIBUS Module Installed.....................................................................24

11. DIAGRAMS OF CONNECTION CABLES.....................................................................................................25

12. ERROR MESSAGES .....................................................................................................................................26