4. WARRANTY CONDITIONS

A. RADWAG feels obliged to repair or exchange all elements that appear to

be faulty by production or by construction.

B. Defining defects of unclear origin and means of their elimination can only

be realized with the assistance of the manufacturer and the user

representatives.

C. RADWAG does not bear any responsibility for damage or losses

resulting from unauthorized or inadequate performing of production or

service processes.

D. The warranty does not cover:

mechanical damage caused by product exploitation other than

intended, damage of thermal and chemical origin, damage caused by

lightning, overvoltage in the power network or other random event,

inappropriate cleaning habits.

E. Loss of warranty takes place if:

a repair is carried out outside RADWAG authorized service point,

service claims intrusion into mechanical or electronic construction by

unauthorized people,

the device does not have data plates or they are damaged.

F. For detailed warranty conditions read the warranty certificate.

G. Contact with the central authorized service: +48 (48) 386 63 30.

5. SECURITY REQUIREMENTS

Prior to the first use, carefully read this user manual. Use the weighing device

only as intended.

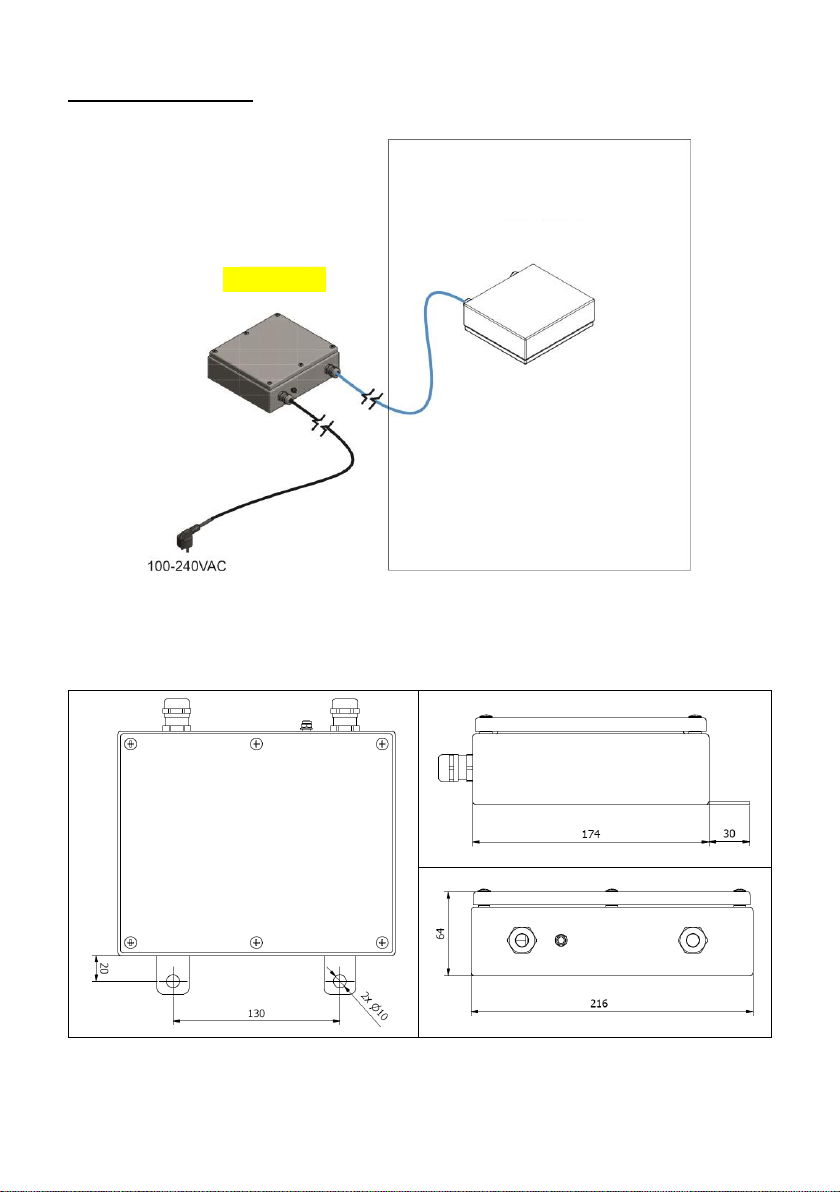

Power supply, depending on the version, can be used in specific areas:

PM02.EX-1-* power supply intended for operation in hazardous area,

-zone 1 and 2 where there is a risk of explosion due to mixture of air with

vapour, mist or gas, classified as explosion group IIC, IIB and IIA and as

temperature class T1, T2, T3, T4.

-zone 21 and 22 where there is a risk of explosion due to mixture of air

with dust, flammable fibres and volatile fuels, classified as explosion

group IIIC, IIIB and IIIA.

Power supply marking:

- for gases: II 2G Ex eb mb [ib] IIC T4 Gb, and

- for dusts: II 2D Ex tb [ib] IIIC T70°C Db.

PM02.EX-2-* power supply intended for operation outside hazardous area

(in safe area), it is equipped with intrinsically safe circuits which may be

placed in: