5

RailKing 2-6-0 Operating Manual

RAILKING

roadbed base. Once the knock-out has been removed, snap the lighted

lockon into the roadbed taking care to make sure that the lockon arms

snap into the roadbed electrical receptors. To complete the connection

between the RiteTrax® track section and the transformer, simply plug in

the color-coded wire harness that was included in your set.

Preparing the Locomotive

Before you fun your locomotive, you must• oil the locomotive and

tender chassis and• prime the smoke element.

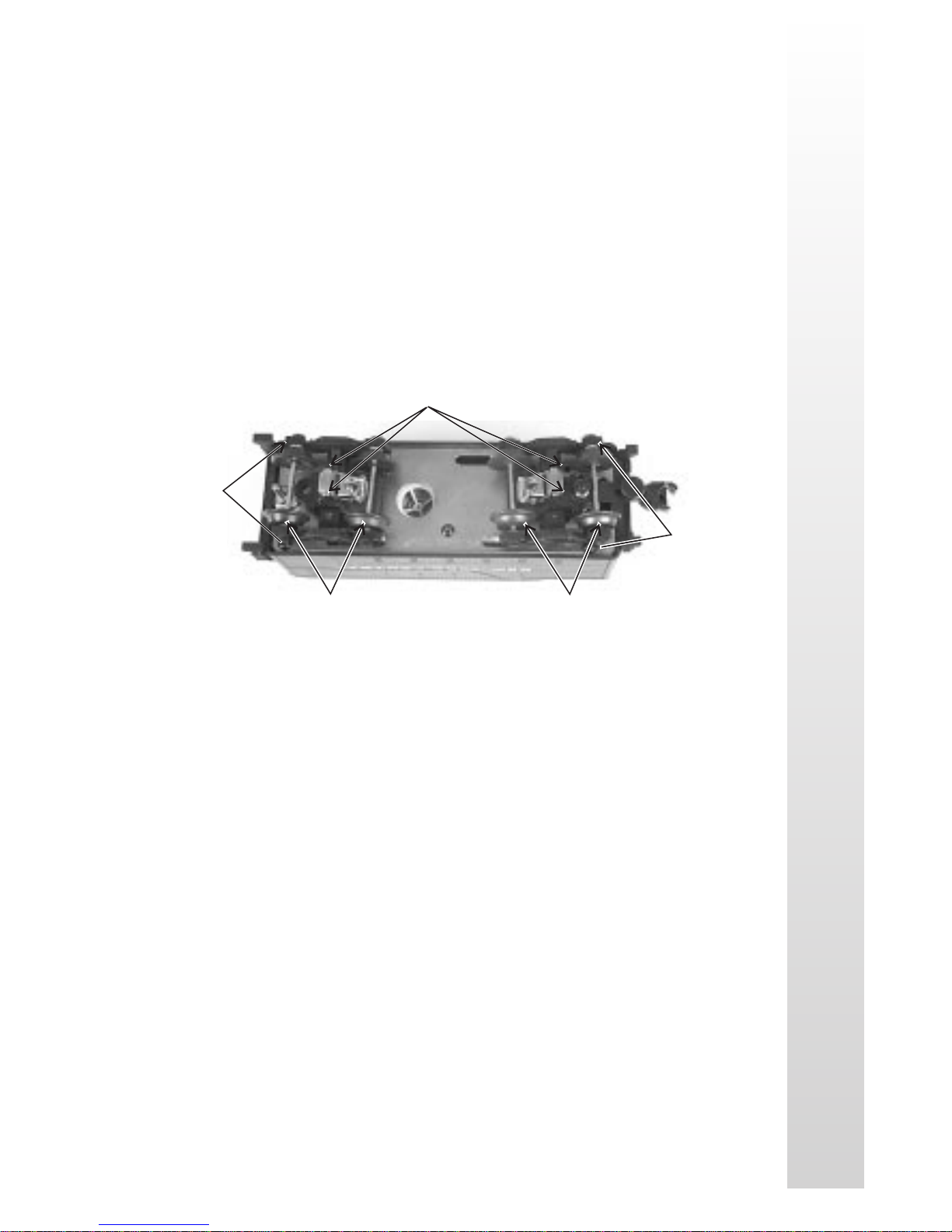

Oiling the locomotive and Tender

Before you run the locomotive and tender, use a light household or

hobby oil to lubricate side rods, linkage components, and pick up

rollers. Apply a small drop of oil (a pinpoint oiler will help place the

right amount of oil where you need it) to each of the points indicated

by an “L” in the diagrams in figures [ ] and [ ]. You may also what to

use either a locomotive repair cradle or an old towel folded over to

provide a protective bed for the locomotive shell while you’re working

on it.

Because the locomotives’s internal gearing has been greased at the

factory, you shouldn’t need to add more grease until you have run the

locomotive for 50 hours or owned it for a year, whichever comes first.

See the section on lubrication, pages(s) [ ], for detail.

Priming the Smoke Element

All locomotive models are equipped with an operating smoke system

that must be primed with smoke fluid before operating to prevent

damage to the smoke element. Adding 20 to 25 drops of smoke fluid

through the smoke stack should be sufficient.

If you don’t want to use the smoke, system, or if you don’t have

smoke fluid on hand, but want to run your locomotive, turn the

smoke unit switch to the OFF position. You will find the smoke unit

switch under the trailing truck. (See figure [3] on page [4].) Turning the

smoke unit switch to OFF will prevent damage to the un-primed smoke