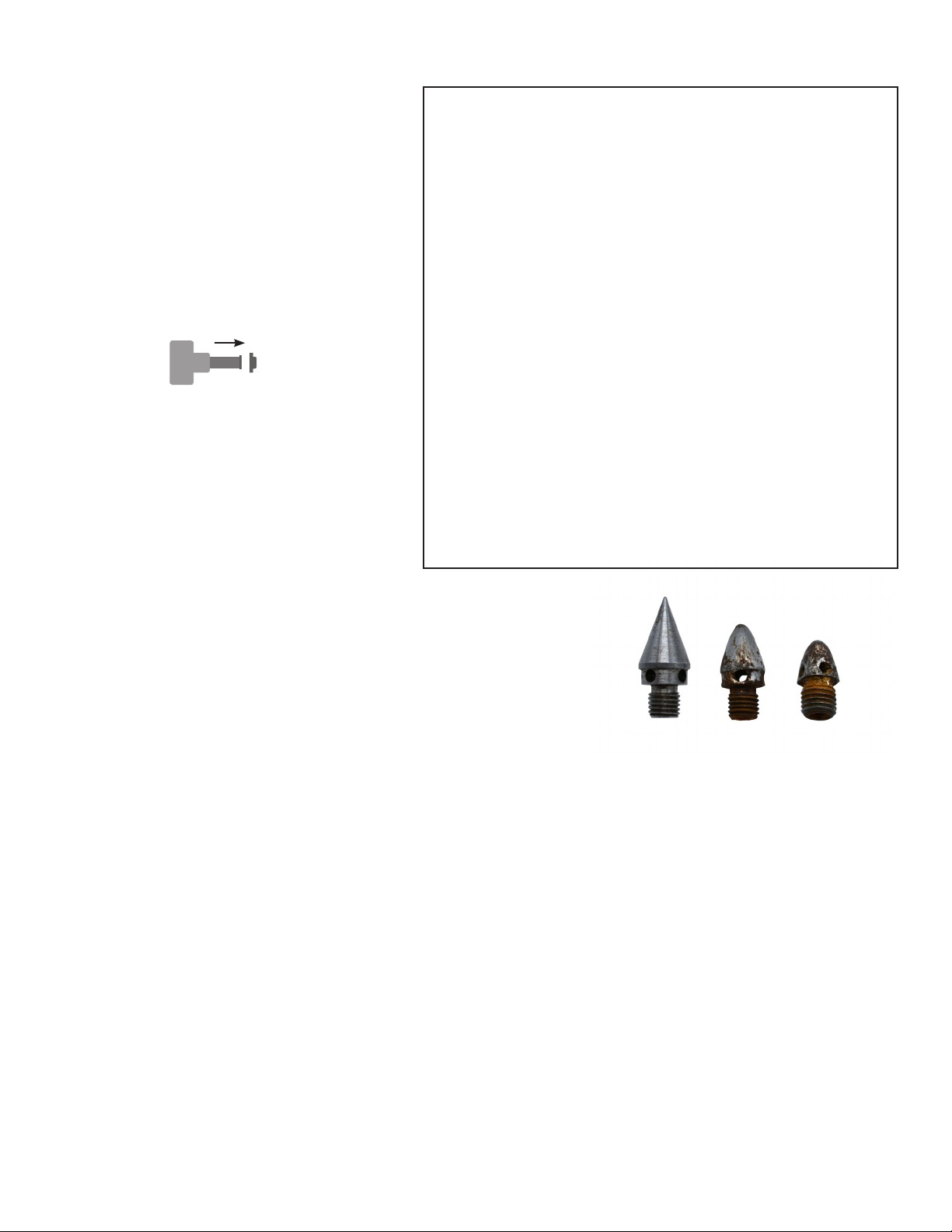

Good Replace

Soon

Replace

Now

General Care and Upkeep

1. DO NOT run fertilizers through HTI 2000. They are too

abrasive on the aluminum and will rapidly clog the filter.

2. Clean after each day of use following the

recommendations outlined in the cleaning section

of this manual.

3. Do not store or use below freezing temperatures.

4. Do not operate the HTI 2000 when the tank reservoir

is empty as it may continue to indicate the chamber

is filling. When the HTI 2000 is drawing upon an empty

reservoir there is a noticeable change in performance.

5. Probe tip will wear with use. Replace when worn to

prevent particulates from clogging product outflow

ports (see below).

Maintaining Your HTI 2000

Daily Cleaning

1. At the end of the application day, run 2000ml of

water through the HTI 2000 using the same fill and

inject buttons as application.

2. Using proper PPE, remove filter from the inline filter

housing and rinse it o to make sure any sediment

is removed from the wire mesh as a clogged filter

will impede application of the product.

3. Store in dry area above 32F and below 110F. Ensure

that no material is present in the injection cylinder

before storing.

4. Leave filter cap removed to prevent rust and

encourage drying.

End of the Season

Here is a list of advice for winterizing and keeping your HTI in shape for spring:

1. Clean all dirt and debris from the exterior of the HTI

2. Cycle clean water through the HTI - recommended minimum: 1 gallon, about 16 cycles

3. Remove the filter from the filter housing and clean with a wire brush to remove rust and debris

(battery post cleaner or other metal wire brush will also suce).

4. Store the filter separately in a clean and dry location until use the following season to prevent rusting.

5. Remove & clean rust and debris from the injection probe tip. It is recommended to store this part separately in a clean and dry area.

Consider replacing if worn.

6. Lubricate all O-rings, especially in the piston manifold, with a synthetic silicone lubricant (i.e. Molykote 111 or Super Lube).

7. Lubricate the ‘Fill and ‘Inject’ button components with synthetic silicone lubricant (i.e. Molykote 111 or Super Lube).

8. Always allow the HTI to dry as much as possible before long-term storage. An air compressor can be used to help dry the

interior of the unit.

9. Store the HTI upright to help prevent any trapped moisture from pooling in the unit.

10. Store the HTI above freezing. Freezing temperatures will cause any moisture in the unit to freeze and expand, which may

crack the piston manifold and/or damage the tubing.

4 Tech Support: 877-272-6747

Replacing Probe Tip

Frequency of use and local soil conditions will aect how often the probe tip

needs to be replaced. Inspect weekly and replace when needed.

1. Use a vice grip to unscrew probe tip.

2. Inspect tip and shaft for particulates or clogs. If either are present,

use a paper clip to remove particulates and clogs. Replace worn out tip.

3. Use vice grip to screw probe tip back on.