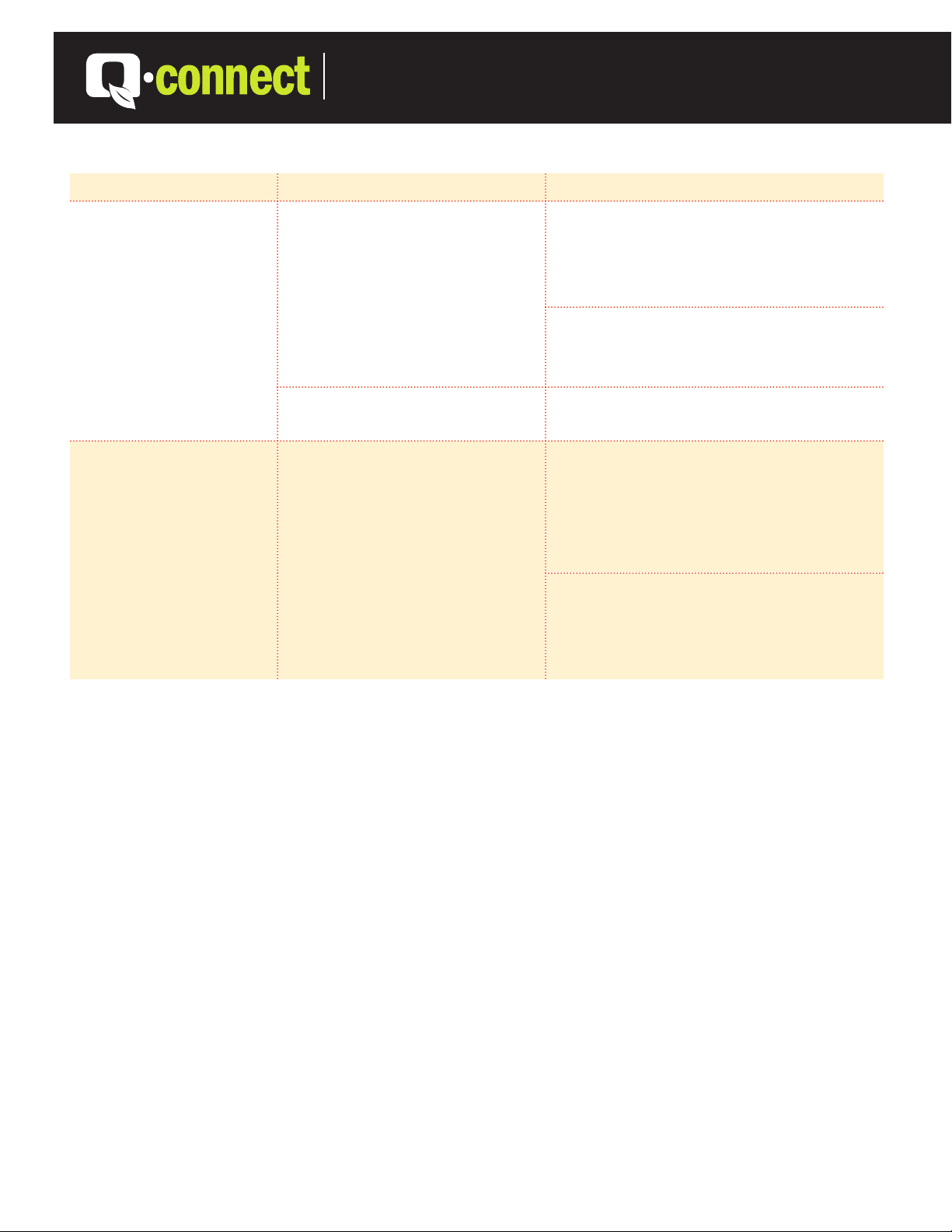

TROUBLESHOOTING

SYMPTOM POSSIBLE PROBLEM SOLUTION

The bottle cannot be

pressurized or does not

hold pressure

Improper seal between bike pump and

Schrader valve Re-attach the bike pump securely

Faulty or damaged bike pump Replace

Faulty or damaged Schrader valve Repair or replace Schrader valve

Main bottle valve is open, with tubing

disconnected

Ensure the harness tubing is connected

to the bottle cap

Hissing/leaking sound

when bottle is pressur-

ized*

*Depressurize the system

before attempting repairs

Bottle top not securely threaded onto

bottle

Remove and re-attach bottle top assem-

bly to bottle

Improper seal between bike pump and

Schrader valve Re-attach the bike pump securely

Duckbill valve is damaged or worn Clean duckbill valve, replace duckbill

valve, or plug valve with rubber valve plug

Leaking Schrader valve Clean or replace valve stem

Leaking seal or connection between

bottle top components

Call our Solution Center for technical

support: 877-272-6747

The black push-to-con-

nect tee is leaking

Tubing only partially inserted Push tubing in farther

Tubing has been scored too deeply Restore end or replace tubing segment

(See Repair Instructions Section IV.)

Tubing may have been cut incorrectly Re-cut end to ensure straight edge, or

replace tubing segment

Damaged push-to-connect fitting Replace push-to-connect tee

Tubing cannot be

inserted into push-to-

connect fitting

Obstruction in push-to-connect fitting Inspect push-to-connect fitting for ob-

struction, such as a broken tubing end

Hardened product residue is

preventing push-to-connect function

Soak push-to-connect fitting or tee in

cleaning solution to loosen residue

Harness connector will

not snap together Dirt/residue build-up Thoroughly clean harness connectors

One injection tip will

not inject

Bad injection site in tree Try new injection site

Plugged injection tip or handle Clean injection tee components

Pressure leak somewhere in the lines

Ensure that all injection tees are securely

inserted into their injection sites and that

no tees are leaking

Tip spins in handle

(can’t be tightened)

Handle threads are stripped Replace injection tee handle

Set screw is not properly tightened Remove set screw and injection tip

Replace and tighten the tip and set screw

Refer to the table below to troubleshoot the Q-connect system.

continued on next page » 7

• Purge all fluid from the lines after each use and prior to changing

chemistries.

• It is recommended that you clean your Q-connect after every day of use with

a dilute isopropyl alcohol solution (1 part 70% isopropyl alcohol to 2 parts water).

• It is recommended to run water through the unit after the cleaning solution,

and allow the lines to dry completely before storage.

• Thoroughly clean bottle cap, pressure relief valve, and harness connector

weekly or after heavy use.

• Store your Q-connect in a dry area free from dust and particulate matter.

• Store above 32°F (0°C) and below 110°F (43°C).

GENERAL CARE & STORAGE

APPROVED PRODUCT LIST

The Q-connect is a versatile workhorse for your tree injection plans. We are

actively engaged in research to broaden the usefulness of this tool. Refer to

our website for a list of approved products.

Approved Product List website link:

www.treecarescience.com/q-connect

For tech support and protocols call 877-272-6747

6