ONTENTSC

CHAPTER 1 PREFACE........................................................................................................................................................5

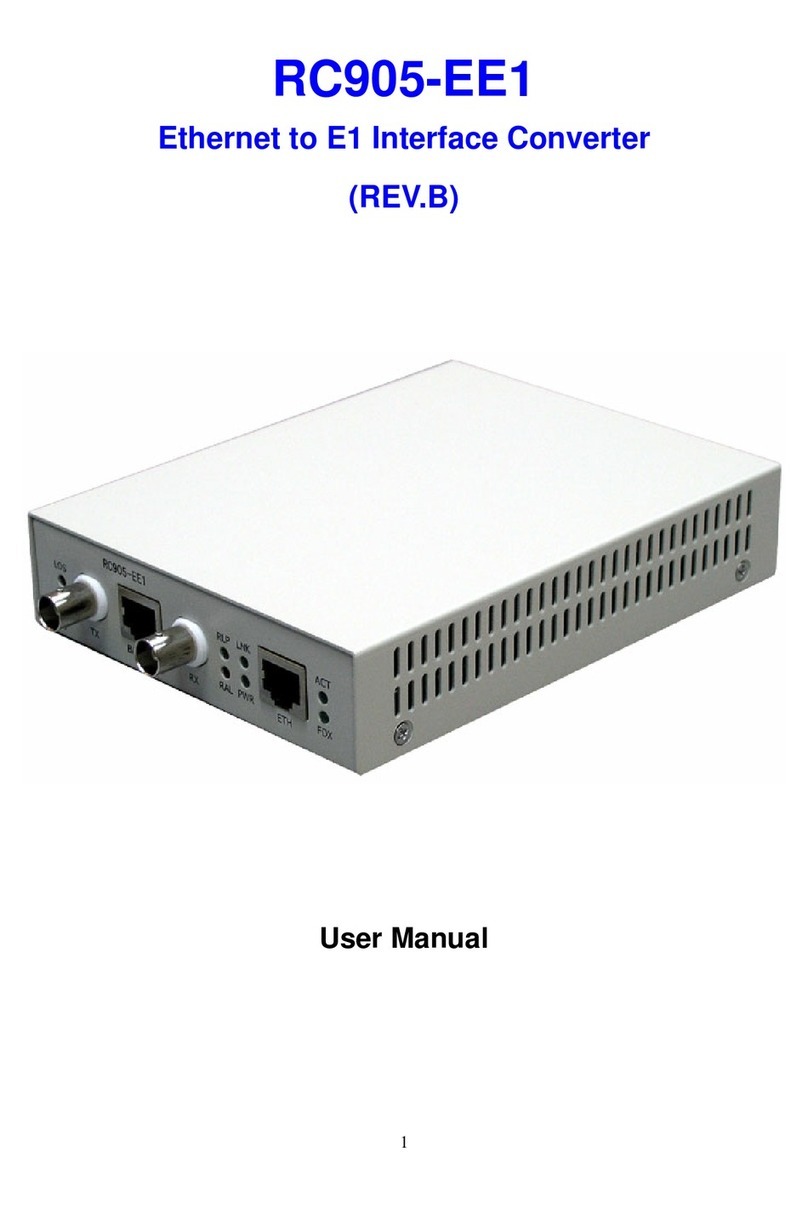

CHAPTER 2 PRODUCT OVERVIEW................................................................................................................................7

CHAPTER 3 TECHNICALSPECIFICATION ..................................................................................................................8

2.1 BASIC SPECIFICATION ...........................................................................................................................................................8

2.2 OPTICAL INTERFACE SPECIFICATION.....................................................................................................................................8

CHAPTER 4 INSTALLATION PREPARATION AND CONNECTION .........................................................................9

3.1 MATCHING FIBER WITH THE MEDIA CONVERTER ..................................................................................................................9

3.2 FIBER OPTIC TYPES...............................................................................................................................................................9

3.3 CONNECTING THE FIBER INTERFACE OF MEDIA CONVERTER................................................................................................9

3.4 BACK-TO-BACK CONNECTING MEDIA CONVERTERS.............................................................................................................9

3.5 CONNECTING MEDIA CONVERTERS TO ETHERNET DEVICES (UTP INTERFACE)..................................................................10

3.6 INSTALLING THE MODULE (IN CHASSIS)ONTO THE RACK...................................................................................................10

3.7 INSTALLING WITH DC POWER SUPPLY................................................................................................................................10

3.8 ELIGIBLE POWER SUPPLY....................................................................................................................................................11

CHAPTER 5 STATUS INDICATORS................................................................................................................................12

4.1 THE FRONT PANEL OF RC552-FE(A)..................................................................................................................................12

4.2 THE INDICATORS OF RC552-FE(A).....................................................................................................................................12

4.3 THE INDICATORS OF 16-SLOT CHASSIS................................................................................................................................12

CHAPTER 6 DEVICE SETUP...........................................................................................................................................13

5.1 COPPER INTERFACE CONFIGURATION DIP-SWITCH SW20 ..................................................................................................13

5.2 FUNCTION CONFIGURATION DIP-SWITCH SW21.................................................................................................................13

5.3 FIBER INTERFACE CONFIGURATION DIP-SWITCH SW22......................................................................................................14

CHAPTER 7 NETWORK MANAGEMENT FEATURES...............................................................................................15

6.1 REVIEW THE MODULE.........................................................................................................................................................15

6.2 CONFIGURE THE MODULE...................................................................................................................................................15

6.3 LOOPBACK TEST .................................................................................................................................................................16

6.4 RESET THE MODULE............................................................................................................................................................16

CHAPTER 8 CONFIGURE AND MANAGE RC552-FE(A) THROUGH CLI..............................................................17

7.1 MENU INTRODUCTION.........................................................................................................................................................17

7.2 CONFIGURE RC552-FE(A) THROUGH CONSOLE .................................................................................................................17

7.2.1 Login...........................................................................................................................................................................17

7.2.2 Display the Module Status...........................................................................................................................................18

7.2.3 Configure the Module Loopback.................................................................................................................................18

7.2.4 Display the Module Fault Propagation Status............................................................................................................19

7.2.5 FPGA Firmware Online Upgrade...............................................................................................................................20

7.2.6 Exit the Console..........................................................................................................................................................22

CHAPTER 9 IEEE802.3AH OAM FUNCTIONS.............................................................................................................23

8.1 OVERVIEW ..........................................................................................................................................................................23

8.2 OAM DISCOVERY ...............................................................................................................................................................23

8.3 MIB VARIABLE REPLY ........................................................................................................................................................23

8.4 LOOPBACK ..........................................................................................................................................................................23

8.5 DYING GASPALARM...........................................................................................................................................................23

APPENDIX A. FAQ ...................................................................................................................................................................24