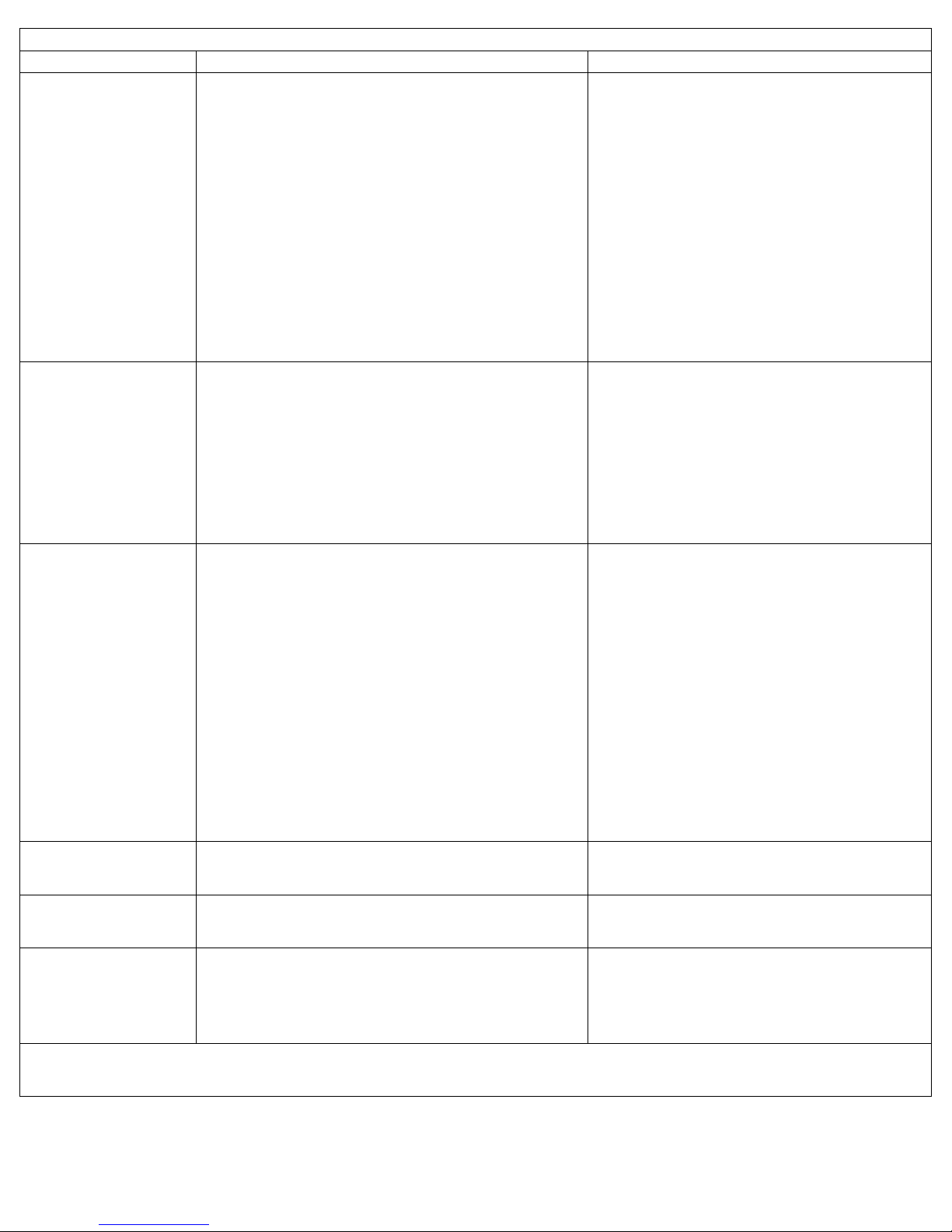

Section 22: Raising the Saw Head to Vertical Position

22.1 Loosen the LOCKING BOLT (ITEM 35).

22.2 EXTEND THE VERTICAL SUPPORT LEG (Item 36)

about 6”.

22.3 Re-lock the locking bolt.

22.4 Lift the saw head so that it is perpendicular to the saw bed.

(Item 54).

22.5 With the saw head held upright, readust the position of the

VERTICAL SUPPORT LEG to touch the floor.

22.6 Re-lock the LOCKING BOLT.

22.7 Place the VERTICAL TABLE (Item 9) in place with about

1 ‘ clearance between it and the lower BEARING GUIDE

assembly. (Item 18).

Section 23: Vertical Operation

Although this machine will be used primarily as a cutoff saw,

— Notching, Slitting, and Contour Work will be done at times

with the saw head in the vertical position.

A VERTICAL TABLE (Item 9) is included with this bandsaw,

for this purpose.

For vertical operation, be sure that a fine-tooth saw blade is

installed in the saw, since in vertical operation the material to

be cut will most likely be of a light gauge.

23.1 Raise the saw head to its vertical position, (Section 21)

23.2 Install the VERTICAL TABLE.

23.3 Set the top BLADE GUIDE (Item 18) to a height above

the VERTICAL TABLE equal to 1/8” more than the thickness

of the stock material.

23.4 Proceed with cutting.

The same speed principles apply to vertical cutting as apply in

the case of horizontal cutting.

Feeding the material to be cut into the saw blade is obviously a

hand operation in vertical cutting, so

EXERCISE CAUTION AT ALL TIMES.

With practice, you will readily beome aware of the amount of

pressure that will be needed to achieve the best cutting

efficiency, (See Section 6).

Section 24: Switch Actuator Adjustment

Adjust the SWITCH ACTUATOR (Item 44) up or down so that

the ON-OFF SWITCH (Item 45) is turned “OFF” when the saw

has cut through the workpiece.

Section 25: Programming

To avoid costly, time consuming changeovers and re-

adjustments, it is wise to plan in advance the cuts

to be made, and do them all in the same set up.

Section 26: Important Notes

The BLADE GUIDE BEARING adjustments outlined in

Sections 12 and 13 are the most impor tant adjustments on

your saw. It is impossible to get satisfactory work from

your saw if the BLADE GUIDES are not properly

adjusted.

The BLADE GUIDES are adjusted and power tested with

several test cuts before leaving the factory to ensure

proper setting and the need for readjusting should rarely

occur when the saw is properly used.

However, if the BLADE GUIDES do get out of

adjustment, it is extremely important to re-adjust them at

once.

If improper adjustment is allowed, the blades will not cut

straight, and if the situation is not corrected, it will cause

serious blade damage.

Because BLADE GUIDE adjustment is a critical factor in

the performance of your saw, it is always best to try a new

blade to see of this will first correct poor cutting before

proceeding with any readjust ing.

If a blade becomes dull on one side sooner than on the

other, forexample, itwill begin cutting crooked.

A simple blade change will correct this problem whereas

the more difficult BLADE GUIDE adjust ment will not.

If a new blade does not correct the problem, check the

BLADE GUIDES for proper spacing.

For most efficient operation and maximum accu racy in

cutting, the BLADE GUIDE BEARINGS should just

touch the blade so that they will still turn freely.

Care should be taken to ensure that the welded blade area

is no thicker than the parent metal.

A minimum of three (3) teeth should be on the workpiece

at all times, for proper cutting, — if the teeth of the blade

are so far apart that they straddle the workpiece, severe

damage to the workpiece and to the blade can result.

CARE MUST BE EXERCISED TO KEEP THE

BLADE FROM RUBBING EXCESSIVELY ON THE

SHOULDER OF THE BLADE WHEELS AS THIS

WILL DAMAGE THE PULLEYS AND/OR BLADE.

5