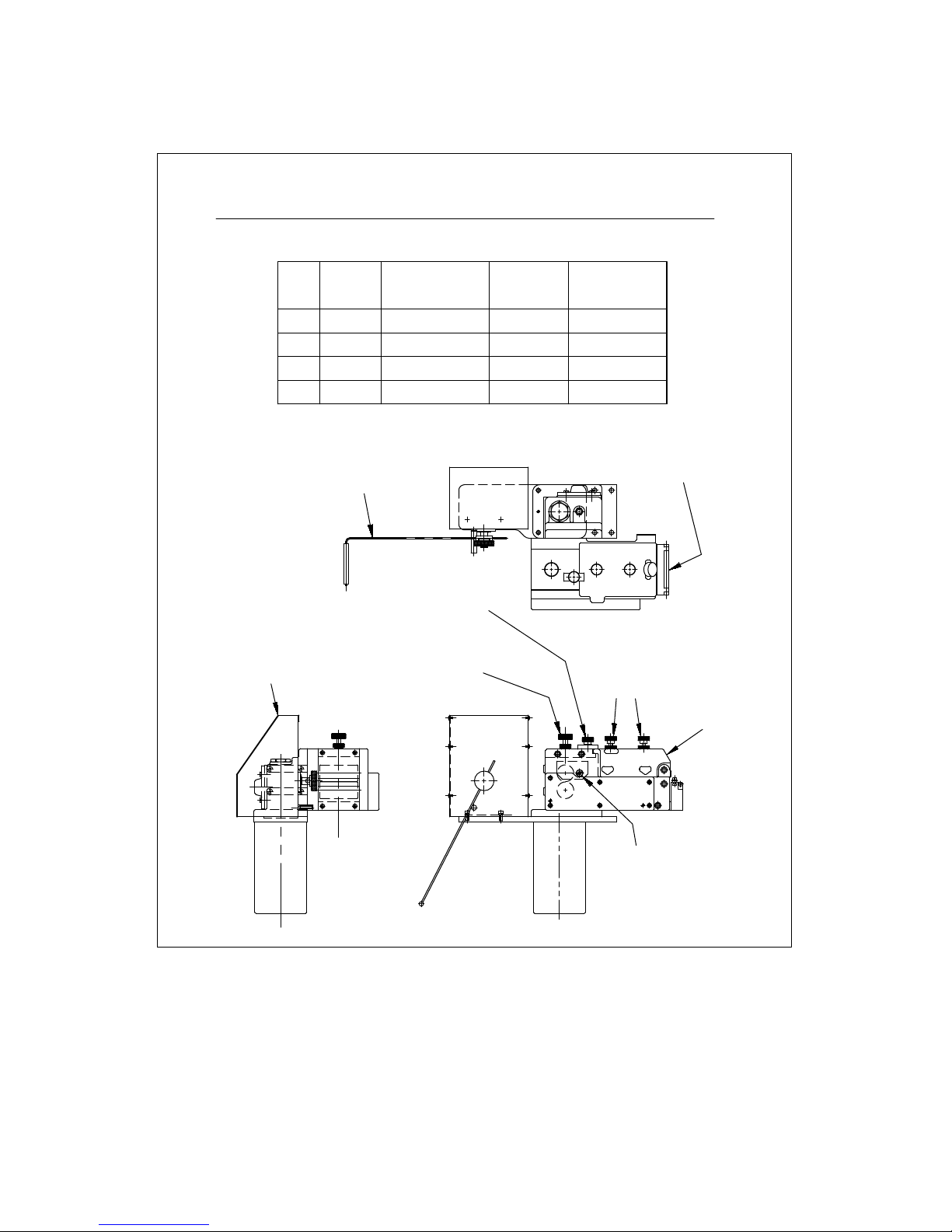

JOG SPEED ADJUSTMENT & DANCER ARM

CALIBRATION

Your straightener was shipped with the dancer arm set up for it's

correct position so the only thing that has to be reset would be

the jog speed if you need your unit to jog faster or slower.

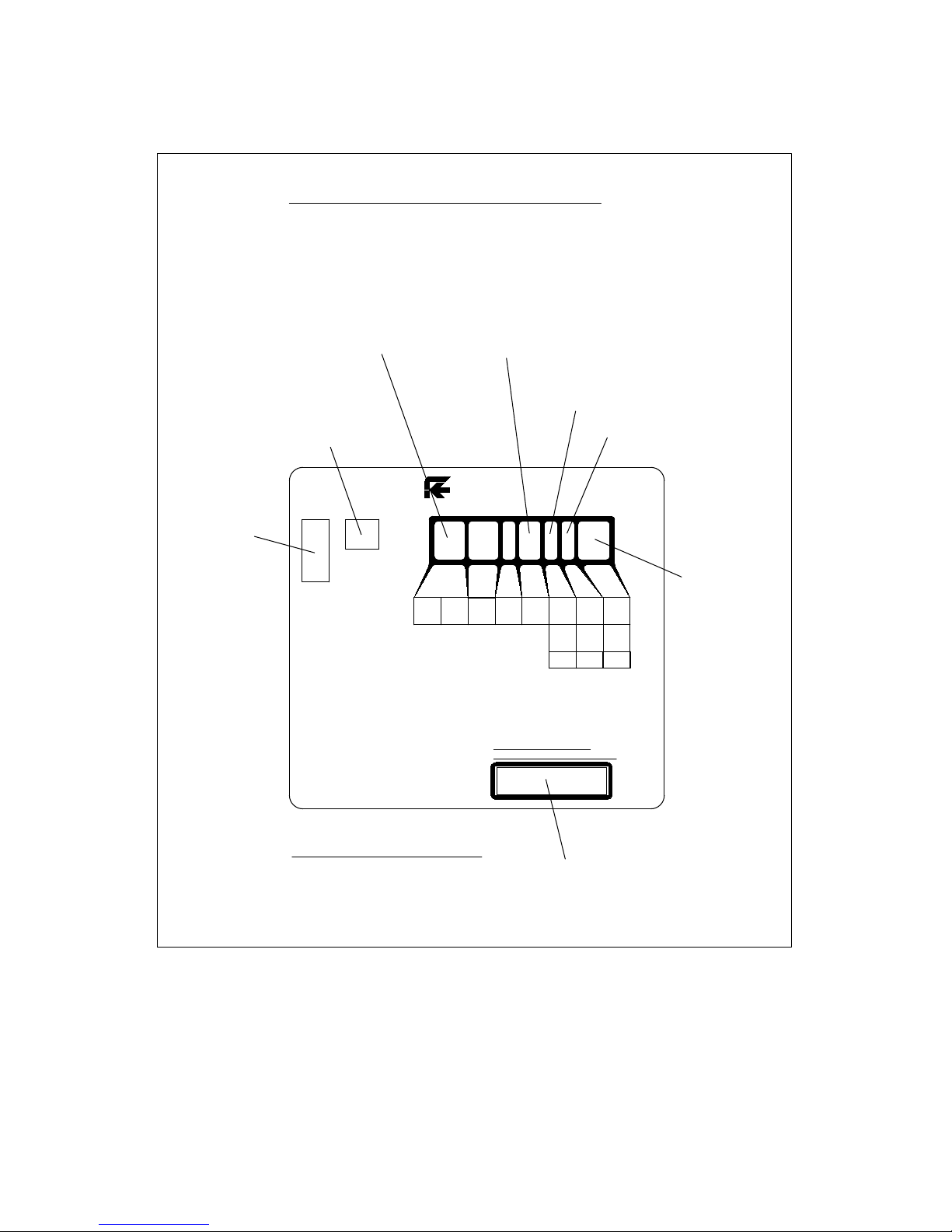

To reset the jog speed, turn off the main power switch. Press and

hold the "Run/Stop/Jog" button while turning the main power switch

on. The first screen you will see will display the jog speed percentage.

SETUP SENSOR

NEXT

To increase the jog speed, press the "Start Speed"

pushbutton. If you want to decrease the jog speed press the

"Start Speed" pushbutton.

%

SPEED

+

%

SPEED

The jog speed is shown in the percent of maximum jog speed.

Once you have set the desired jog speed push the "Run/Stop/Jog"

button once for next. Your jog speed is now set.

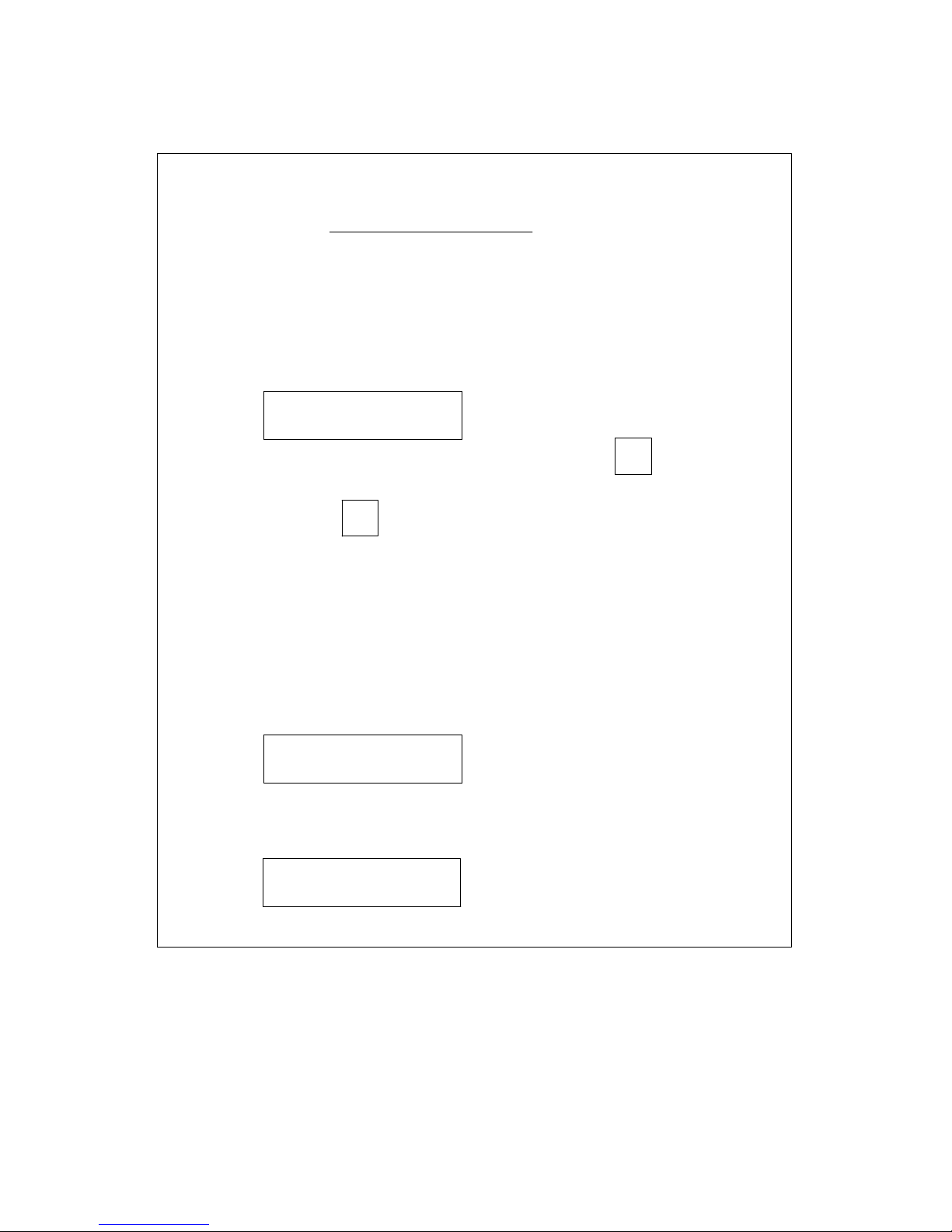

The next screen asks if you want to set up the sensor (commonly

referred to as "dancer arm calibration"). Use the percent speed

Select "no" if all you wanted to do was change the jog speed, select

"yes" if you want to calibrate the dancer arm by resetting the sensor.

buttons to select "yes" or "no".

YES

NO

After making your selection, press

"Run/Stop/Jog" for next.

If you selected "yes" the next screen asks you to set the low set point.

If the dancer arm is resting on the positive stop then just save this

setting by pushing the "Run/Stop/Jog" button.

JOG SPEED

NEXT

23% +

_

_

SENSOR LOW SETPOINT

SAVE xxx

8