55

0579-M090-0

INDEX

0. GENERAL SAFETY PRECAUTIONS..................................................................................6

0.1 IMPORTANT SAFETY INSTRUCTIONS .............................................................................7

0.2 Safety devices ...................................................................................................................................................................... 8

0.3 Indication of outstanding risks ............................................................................................................................................ 14

1. PURPOSE OF THE MACHINE ..........................................................................................17

1.1 Accessories ........................................................................................................................................................................ 18

2. PRE-INSTALLATION AND MOVEMENT ...........................................................................21

3. DESCRIPTION OF THE LIFT .............................................................................................22

3.1 Preparation for use ............................................................................................................................................................. 22

3.2 Main technical characteristics ............................................................................................................................................ 22

3.3 Controls .............................................................................................................................................................................. 22

3.4 Accessories on request ...................................................................................................................................................... 23

3.5 Available accessories ........................................................................................................................................................ 23

4. INSTALLATION ..................................................................................................................24

4.1 Checking the minimum requirements for the installation site ............................................................................................ 24

4.2 Preparing the installation area RAV540U .......................................................................................................................... 25

4.2.1 Special installation on request for RAV540U..................................................................................................................... 27

4.3 Preparing the installation area RAV540IU ........................................................................................................................ 29

4.4 Positioning the footboards and connecting the system in the standard position RAV540U ............................................ 30

4.5 Positioning the footboards and connecting the system in the standard position RAV540IU ............................................ 32

4.6 Connecting to the mains .................................................................................................................................................... 35

4.7 Connecting the power cable .............................................................................................................................................. 35

4.8 Compressed air connection ............................................................................................................................................... 37

4.9 Bleeding the air .................................................................................................................................................................. 39

4.10 Fastening the lift ................................................................................................................................................................. 41

4.11 Checking the safety switches ............................................................................................................................................. 41

4.12 Assembling ramps .............................................................................................................................................................. 43

4.13 Adjusting the levelling of the ramps ................................................................................................................................... 43

4.14 Fitting the ramp support - RAV540IU.................................................................................................................................. 45

4.15 Securing covers and control unit - RAV540U ................................................................................................................... 45

4.16 Operation of the lift ............................................................................................................................................................. 45

4.17 Operational test of lift .......................................................................................................................................................... 45

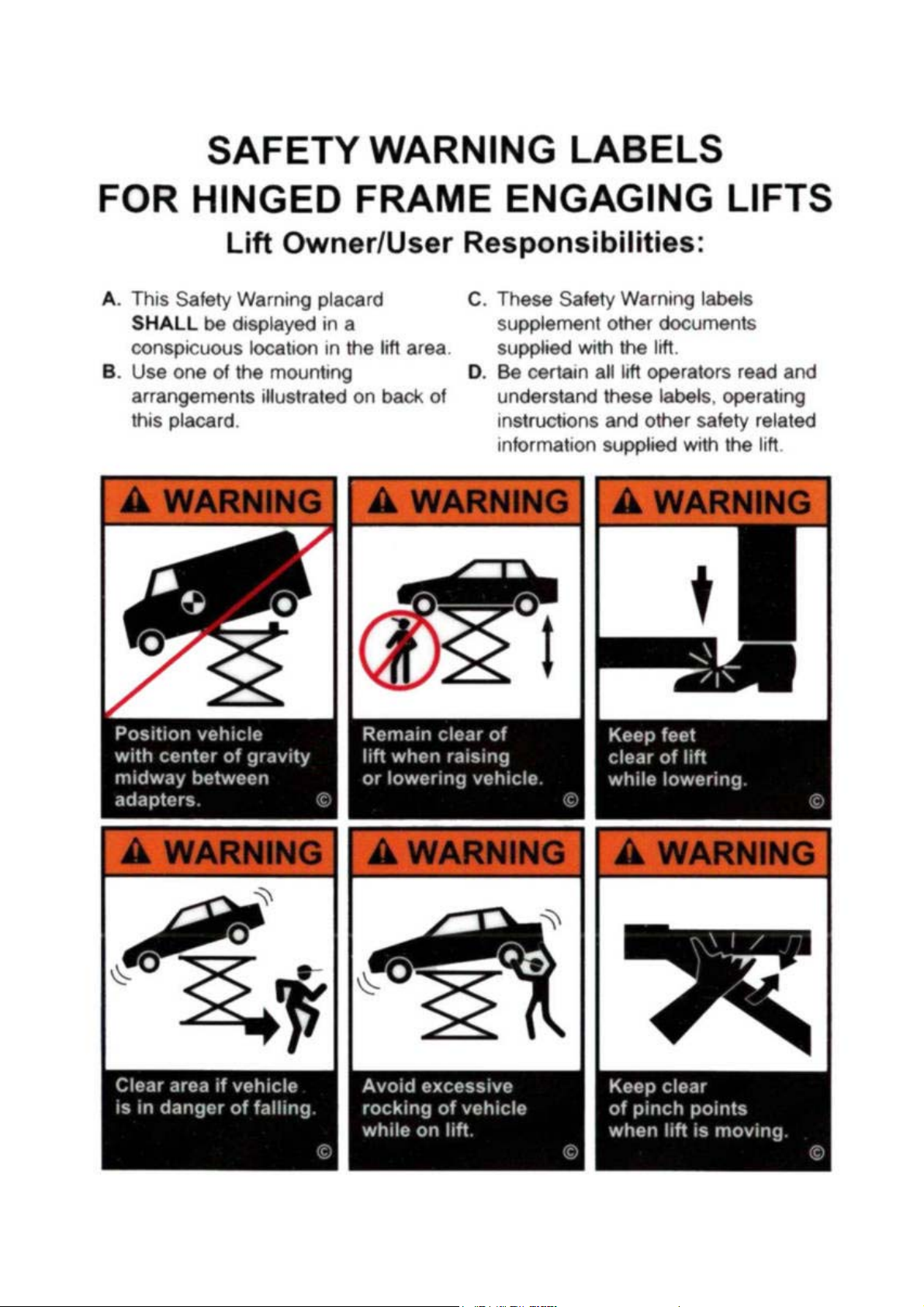

5. INSTRUCTIONS FOR USING THE LIFT ...........................................................................46

5.1 Improper use of the lift ........................................................................................................................................................ 46

5.2 Use of accessories ............................................................................................................................................................. 46

5.3 Training the machine-operating staff ................................................................................................................................. 46

5.4 Important checks to be made ............................................................................................................................................. 47

5.5 Description and function of commands .............................................................................................................................. 49

6. SAFETY ..............................................................................................................................51

6.1 Emergency procedures ...................................................................................................................................................... 51

6.2 Safety devices .................................................................................................................................................................... 51

7. MAINTENANCE .................................................................................................................52

7.1 Lift Lockout/Tagout Procedure ........................................................................................................................................... 52

7.2 Changing the oil in the central unit. ................................................................................................................................... 54

7.3 Cleaning the solenoid valves ............................................................................................................................................. 54

7.4 Cleaning the capacity regulator valve ............................................................................................................................... 54

7.5 Lubrication.......................................................................................................................................................................... 55

7.6 Manual procedure for platforms realignment ..................................................................................................................... 57

8. PROBLEMS ........................................................................................................................58

9. STORAGE...........................................................................................................................60

10. SCRAPPING.......................................................................................................................61

WIRING DIAGRAM ....................................................................................................................62

DIAGRAM OF HYDRAULIC SYSTEM.....................................................................................64

DIAGRAM OF PNEUMATIC SYSTEM ......................................................................................64

11. INSTALLATION AND PERIODIC INSPECTIONS..............................................................66

RESPONSIBILITY OF THE OWNER / EMPLOYER .................................................................67

12. IDENTIFICATION PLATE ...................................................................................................74