Boxer 385D Operator Service Maintenance Manual

8

A message, either written or pictorial,

follows to explain the hazard. Rayco cannot

anticipate every possible circumstance

that might involve a potential hazard. The

warnings in this publication and on the

product are therefore not all inclusive. If you

desire to make use of a tool, procedure,

work method, or operating technique not

specifically recommended by Rayco, you

must use it only if you have accurately

evaluated it and found that it threatens

no one’s safety. You should also ensure

that the product will not be damaged or

made unsafe by the operation, lubrication,

maintenance, or repair procedures that

you choose.

The procedures described in this “Safety”

section may not be fully explained here,

but a more complete explanation is given

in the “Operation”, or in the “Maintenance”

section.

The information, specifications, and

illustrations in this publication are on the

basis of information that was available at

the time that the publication was written.

The specifications, torques, pressures,

measurements, adjustments, illustrations,

and other items can change at any time.

These changes can affect the service that is

given to the product. Obtain the complete

and most current information before you

start any job. Rayco dealers have the most

current information available.

Rayco Manufacturing, Inc. is greatly

concerned with the safety of the operator,

as well as all in the vicinity of his work.

Rayco has provided shields, guards, safety

decals and other important safety features

to aid in using the machine properly. In

order to further ensure your safety we ask

that you properly operate and service your

machine.

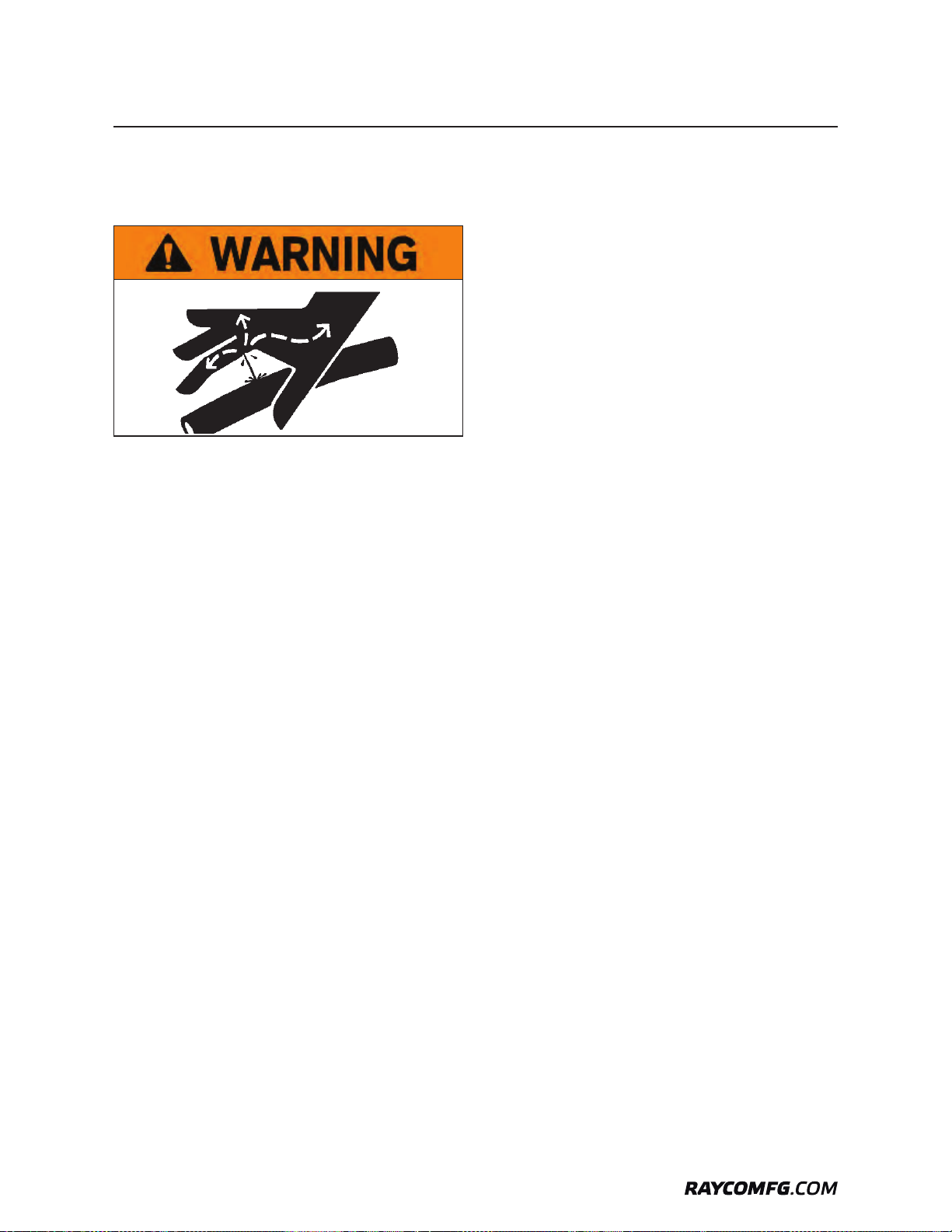

This machine is capable of amputating

hands and feet and throwing objects.

Failure to observe safety instructions,

improper operation, lubrication,

maintenance, or repair of this product

could result in severe injury or death.

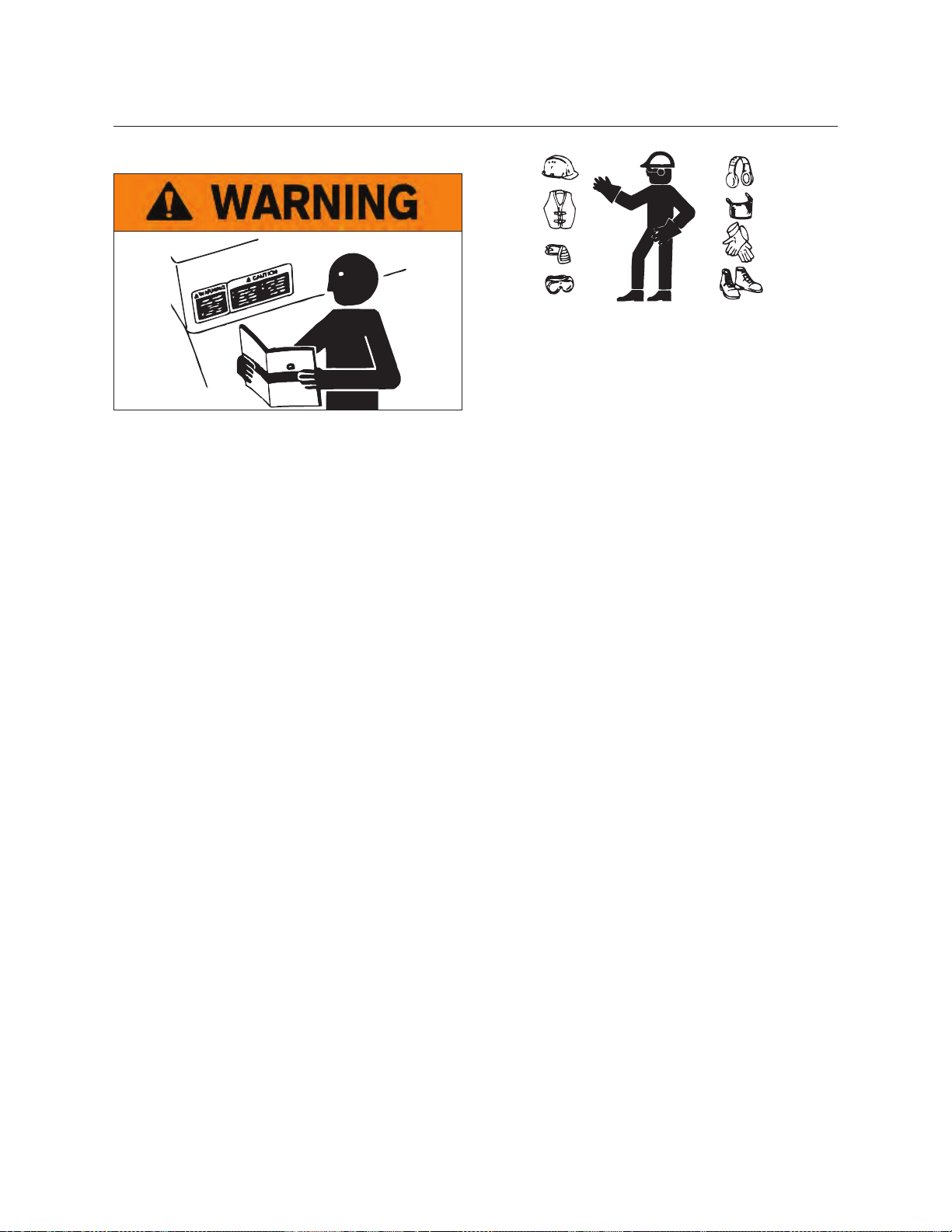

Do not operate or perform any lubrication,

maintenance, or repair on this product,

until you have read, you understand, and

you decide to do so in compliance with all

of the operation, lubrication, maintenance,

and troubleshooting information contained

in these Operator and Parts Manuals and

that contained in the Engine Operator

Manual, which are included with this

machine. Additional manuals are available

from Rayco or your Rayco dealer.

When replacement parts are required for

this product Rayco recommends using

Rayco replacement parts or parts with

equivalent specifications including but

not limited to, physical dimensions, type,

strength, and material.

FAILURE TO HEED THIS WARNING

WILL LEAD TO PREMATURE FAIL-

URES, PRODUCT DAMAGE, PERSON-

AL INJURY OR DEATH

Safety