55M4000BCE00 REV A

10

2.4 Step #4: “Load data” Entry

Note: these settings reflect the configuration of your system when a load sensor is

fitted and will generally be made during factory testing prior to delivery and should

not need changing.

Some or all of this information may be pre-loaded prior to delivery but all entries should

be verified and edited as required before proceeding. Length units in use will be feet or

meters depending on the setting made for ‘calib units’ in step #3.Please advise Rayco

Wylie of any changes required in this section.

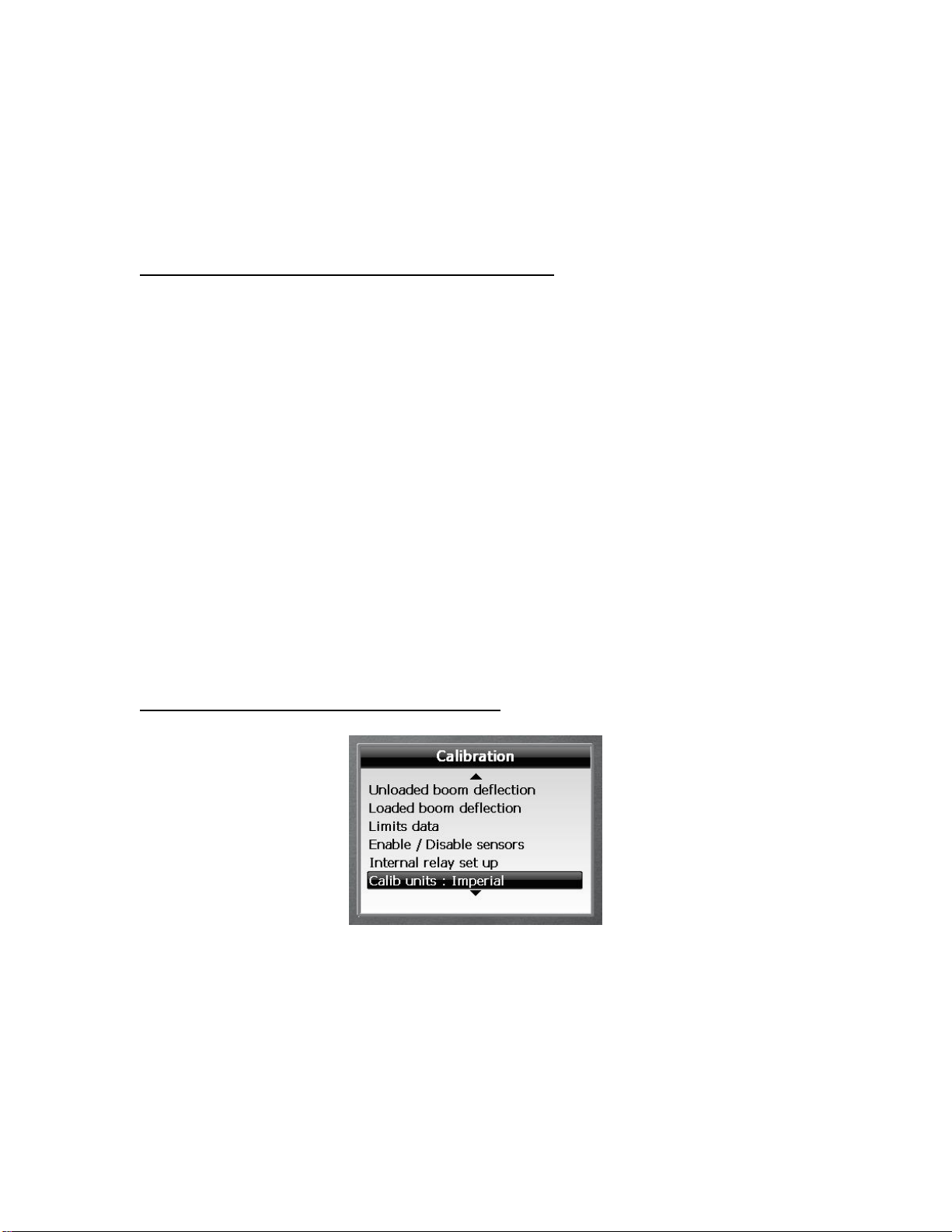

1- In the calibration menu, scroll down to the item "Load data:".

2- Press “”to enter this menu.

3- Scroll to select the item to edit from the list below.

4- Press “”to highlight the value to edit. Scroll up or down to change the value

then Press “”to confirm.

5- Any change made is permanently registered after confirmation.

6- Press Escape Key at any time to exit the menu when done.

Rope Limit Main: This is the maximum tension that the cable is rated for per fall or

part of line (rope SWL) for the main rope.

Rope Limit Aux : This is the maximum tension that the cable is rated for per fall or

part of line (rope SWL) for the auxiliary rope.

Max parts of line: This is the maximum number of parts of line that can be rigged on

the crane and applies to all hoists.

Load Approach (%): Is the %SWL approach limit. If the %SWL is greater than this

value, an intermittent audible alarm will be activated and the yellow display LED will

blink. The external yellow lamp output will be ON.

Note: %SWL = (Load / Capacity) x 100.

Overload (%): Is the %SWL motion cut limit. If the %SWL is greater than this value, a

continuous audible alarm will be activated and the red display LED will be ON. The

external red lamp and audible alarm output will be ON. The motion cut output will

be in the stop condition (cut active).

2.5 Step #5: “Limits data” Entry

This menu contains the approach warning gaps for all the limits that can be set by the

operator in normal mode.