2 GENERAL SAFETY INFORMATION

2017 RAYLASE GmbH MINISCAN II

-en / v1.0.3

2.5 Hazards due to laser radiation

WARNING

This chapter describes hazards that can result due to interaction with the higher-level laser system.

The operator of the higher-level laser system is responsible for safe operation and for securing the

surrounding area to prevent hazards that can be caused by laser radiation. They must ensure

compliance with all applicable conditions, regulations, laws, standards and directives.X2-020

2.5.1 General safety measures

The following general safety measures are to be observed:

To ensure that the laser beam is immediately switched off in the event of a fault, the laser process

must always be monitored. Alternatively, the entire beam path can be in a radiation-proof housing.X2-030 .1

The laser system must be designed in such a way that the laser beam can only be emitted at the

beam output on the deflection unit.X2-030.2

Appropriate protection mechanisms must be in place to prevent unauthorised activation or use of

the laser system.X2-030.3

The maximum permitted input beam diameter may not be exceeded.X2-03 0.4

If the materials to be processed can result in toxic vapours, safe extraction of these must be

ensured. Oxidising material processing and processing with material removal that is precipitated

onto the optics must be handled properly.X2-030.5

2.5.2 Measures to prevent uncontrolled escape of laser radiation.

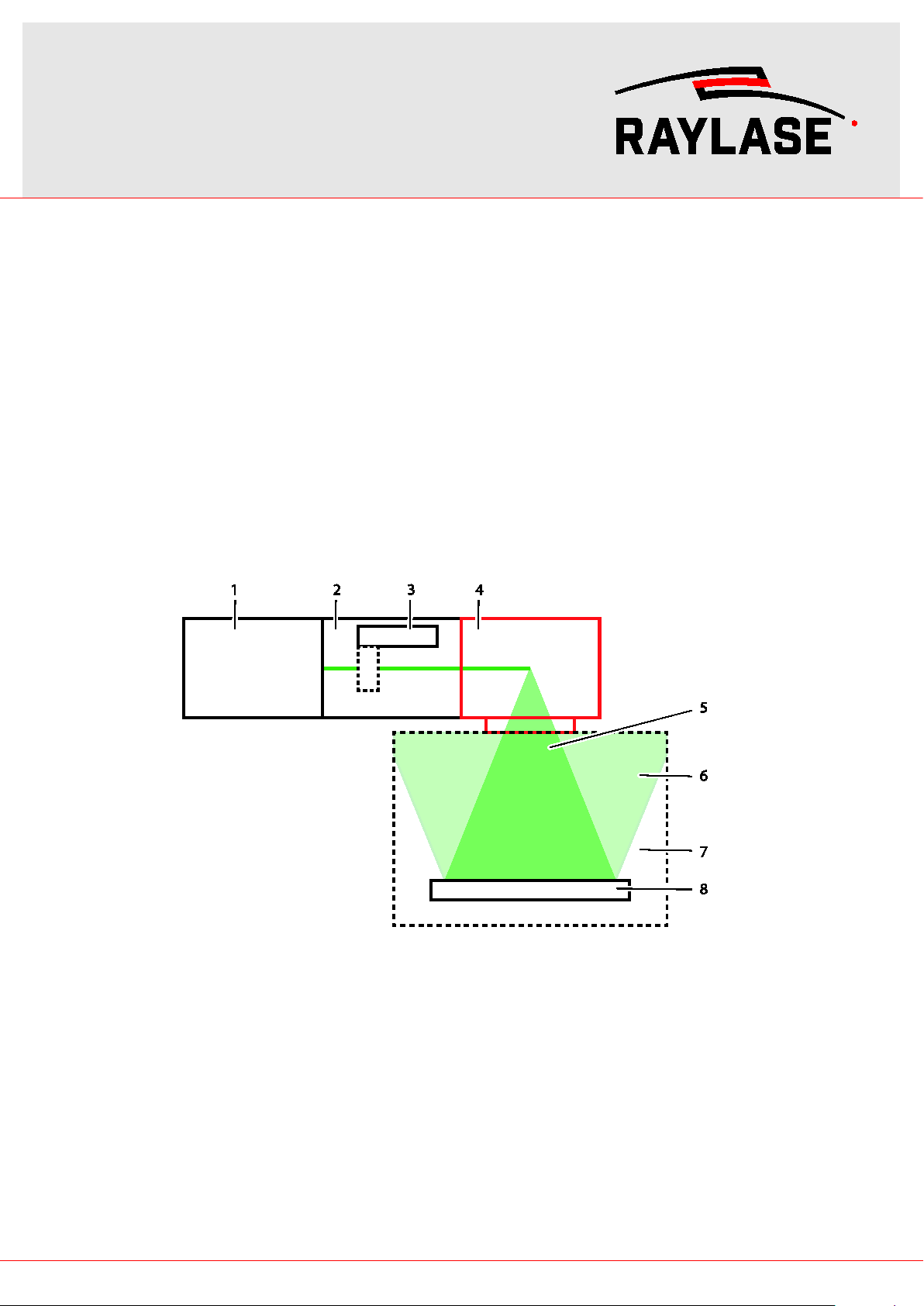

If the mirrors in the deflection unit are destroyed, the laser beam no longer exits the deflection unit at

the intended beam output but remains inside the deflection unit. This leads to heating and, in some

cases, destruction of the housing and can lead to uncontrolled escape of the laser beam.X2 -040

To prevent destruction of the mirrors, the following points must be observed:

At the laser beam input, it is essential that the laser beam strikes the centre of the mirrors. If the

laser beam strikes a mirror towards the edge, the mirror can be overheated and destroyed.X2-040.1

To prevent a loss of control, the plug connections to the deflection unit may only be disconnected

when the laser system and the power supply are switched off.X2 -04 0.2

The deflection unit should always be operated with a lens or protective window.X2-040. 3

The maximum permitted laser power may not be exceeded.X2 -040.4

The deflection unit must be installed in such a way that the mirrors cannot come into contact with

liquids. Liquids change the reflective properties of the mirrors, which can lead to them being

destroyed by the laser beam.X2-040. 5

Before processing highly reflective materials, RAYLASE must be contacted as reflections can lead to

the destruction of the deflection unit.X2-040 .6

In general, correct and careful handling of the optical components must be ensured, particularly

during maintenance and cleaning work. Contaminated or scratched optics can absorb

unacceptable amounts of laser power and thus be destroyed.X2-040.7