RI-D340-IM-V02

1

RI-D340 Instrucon Manual

X 1

Safety related noficaon, symbols and instrucons that appear in this

operang manual or on the equipment must be strictly followed to

ensure the safety of personnel as well as the instrument. If the

equipment is not used in a manner specified by the manufacturer it may

impair the protecon provided by the equipment

· Do not use the equipment if there are mechanical damage

· Do not exceed the stated maximum rangs of the device

· No repairs, maintenance or adjustments are possible

· Read the complete instrucon manual prior to installaon or

operang the unit

· The equipment in its installed state must not come into close

proximity to any heang sources, oils, steam, causc vapours or

other unwanted process by-products

· Do not use in hazardous or classified locaon where explosion or

other dangers can be triggered by the device

PRODUCT SAFETY INSTALLATION PRECAUTIONS

Risk of electric shock!

Only to be installed by a competent person

· To prevent the risk of electrocuon, always isolate and lock-off the

power supply to the equipment prior to undertaking any work

· Always confirm absence of electricity prior to starng work using

appropriate voltage detecon equipment

· Wiring shall be done strictly according to the terminal layout

· Confirm that all connecons are correct before energizing the

equipment

· Roung of cables shall be way from any internal EMI source

· Copper cable should be used

· All wiring to be in accordance with applicable local standards

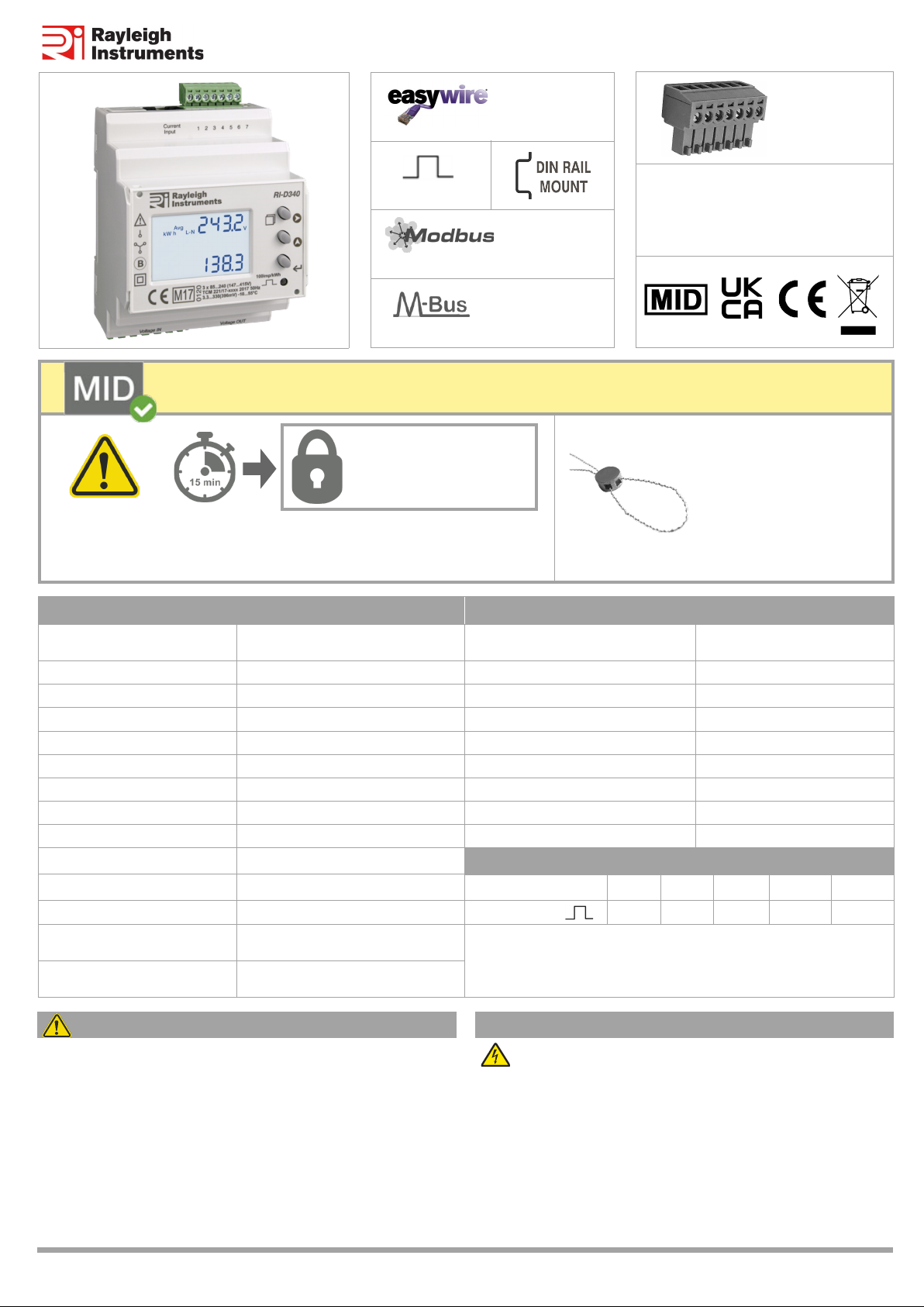

Once Configuraon Mode is entered, ‘Configuraon Lock’ will acvate

aer 15 minutes or if meter is switched off. No further adjustment is

possible for the lockable sengs. Unlock only by returning to supplier.

All terminal covers provided

must be fied. All cable

connecons and terminal

covers of the meter and the

CT must be secured with

sealing hasp.

Installaon must comply with MID cerfied requirements

Configuraon Lock

>> see ‘Configuraon’

for Lockable Sengs

Specificaons Accuracy

Wiring Input 3Ø 4 wire (MID Approved)

1Ø 2 wire - P1, P2, P3 (All MID Approved) Voltage V L-N and V L-L ±0.5% of full scale

Rated Input Voltage 3x 85...240V AC (L-N), 147...415V AC (L-L) Current ±0.5% of full scale

Frequency 45...65Hz (MID approved @50Hz) Frequency for L-N > 20V, L-L > 35V ±0.1% of full scale

CT Primary 1...6,000A configurable Acve, Reacve and Apparent Power 1%

CT Secondary 0.01...1(1.2)A (Meter Input: 330mV) Power Factor ±0.01 of Unity

VT Primary 100...600V configurable Acve Energy EN50470-3: Cl.B

VT Secondary 100...500V AC (L-L) configurable Reacve Energy EN62053-23: Cl.2

Voltage Rated Burden < 8VA

Display Update Rate 1 sec all parameters Wh Resoluon and Default Pulse Weight

Operang / Storage Temperature -10…55°C / -20…75°C

Example

If CT Primary = 200A (CT rao = 200/1 = 200) & VT = 350/350V (VT Rao = 1)

Wh resoluon = 1kWh (200 x 1 = <1500) | Pulse O/P default = 1kWh/pulse

Humidity 0...85% non-condensing

Protecon Degree (IEC/EN60529) IP54 (front of Housing), IP20 (terminals)

Communicaon Modbus RTU over RS485

MBus (EN13757)

Auxiliary Supplied from any phase Apparent Energy Class 1

CT Rao x VT Rao <15 <150 <1500 <15000 >15000

Wh / kArh / VAh / 0.01k 0.1k 1k 0.01M 0.1M

EO&E: Document subject to change

1x 3Ø

1x 1Ø

3x 1Ø

RI-D340-G-C

RI-D340-G-MB

RTU

Pulse SO