8

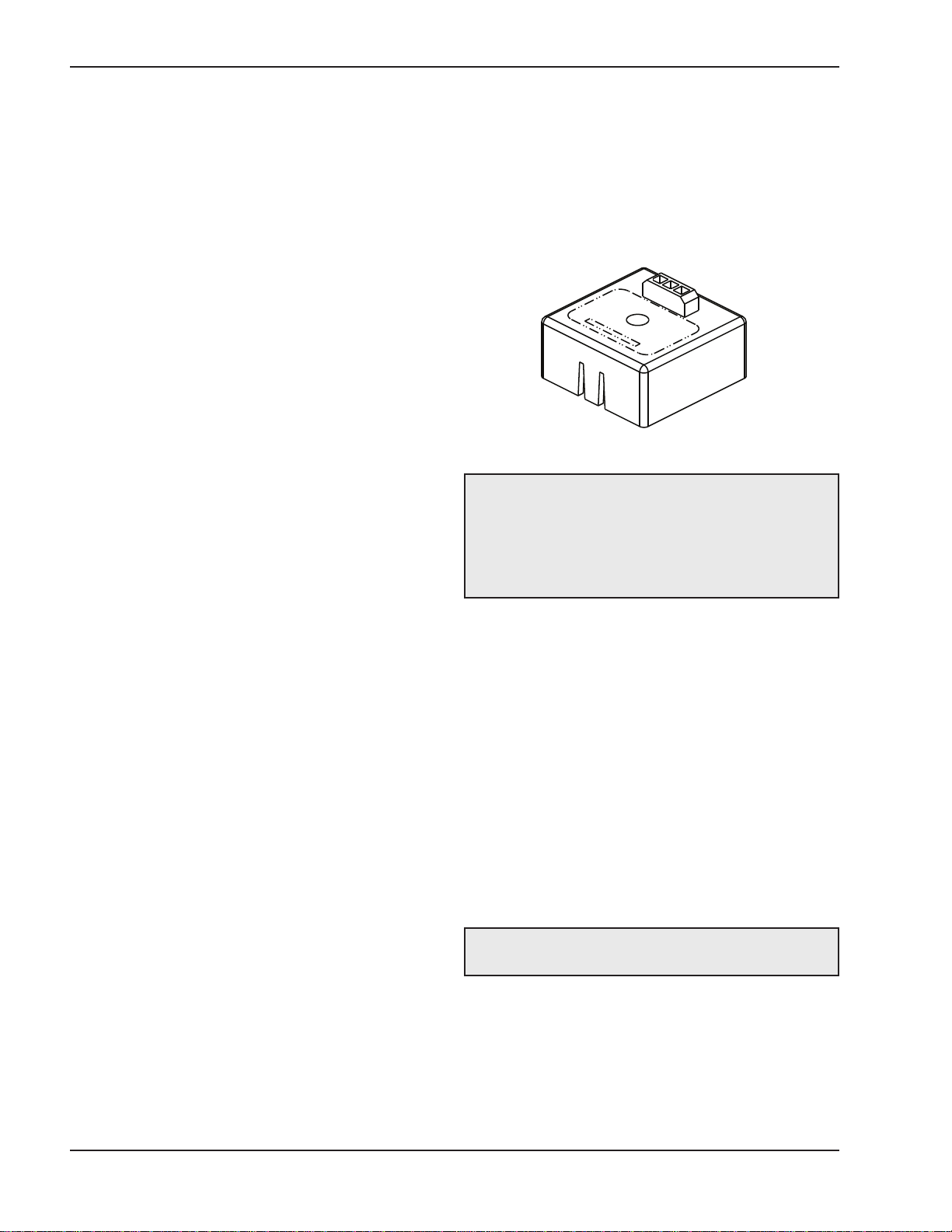

PIM™ DIP Switches

There is an 8-position DIP switch on the PIM™ that

can be field configurable during commissioning. The

UP position is “ON” and the DOWN position of each

DIP switch is “OFF”. The items in BOLD below repre-

sent factory defaults settings.

DIP Switch #1 – Operator Differential

ON = Manual Differential

OFF = Auto Differential

DIP Switch #2 – nalog Input Type

ON = Direct Drive

OFF = Target Temperature

DIP Switch #3 – Pump Post Purge

ON = Pump Post Purge Active

OFF = Pump Post Purge Inactive

DIP Switch #4 – Pump Exercise Enable

ON = Pump Exercise Active

OFF = Pump Exercise Inactive

DIP Switch #5 – EMS/Demands

ON = EMS nalog Input Only

OFF = VERSA IC®Demands Only

DIP Switch #6 – EMS Signal Type

ON = 4-20m *

OFF = 0-10 VDC

DIP Switch #7 – Freeze Protection

ON = Freeze Protection Active

OFF = Freeze Protection Inactive

DIP Switch #8 – Commission Test

ON = Commission Test ctive

OFF = Commission Test Inactive

*NOTE: 4-20m operation requires the use of an

external 500Ω, 1/2W resistor.

PIM™ perator Set-Point Dial

The PIM™ has a set-point dial that is used to deter-

mine the operator set-point applied to the boiler outlet

sensor during “limp-along” operation of the VERS

IC®Control System. The default position of the opera-

tor set-point applied to the boiler outlet sensor dial is

the maximum set-point, which is defined by the PIM™

parameters defined by the ID card. The dial can be

adjusted down to a user-defined level between the

minimum setting of 70°F or the maximum allowed by

the ID card. This function is only active during

“limp-along” operation.

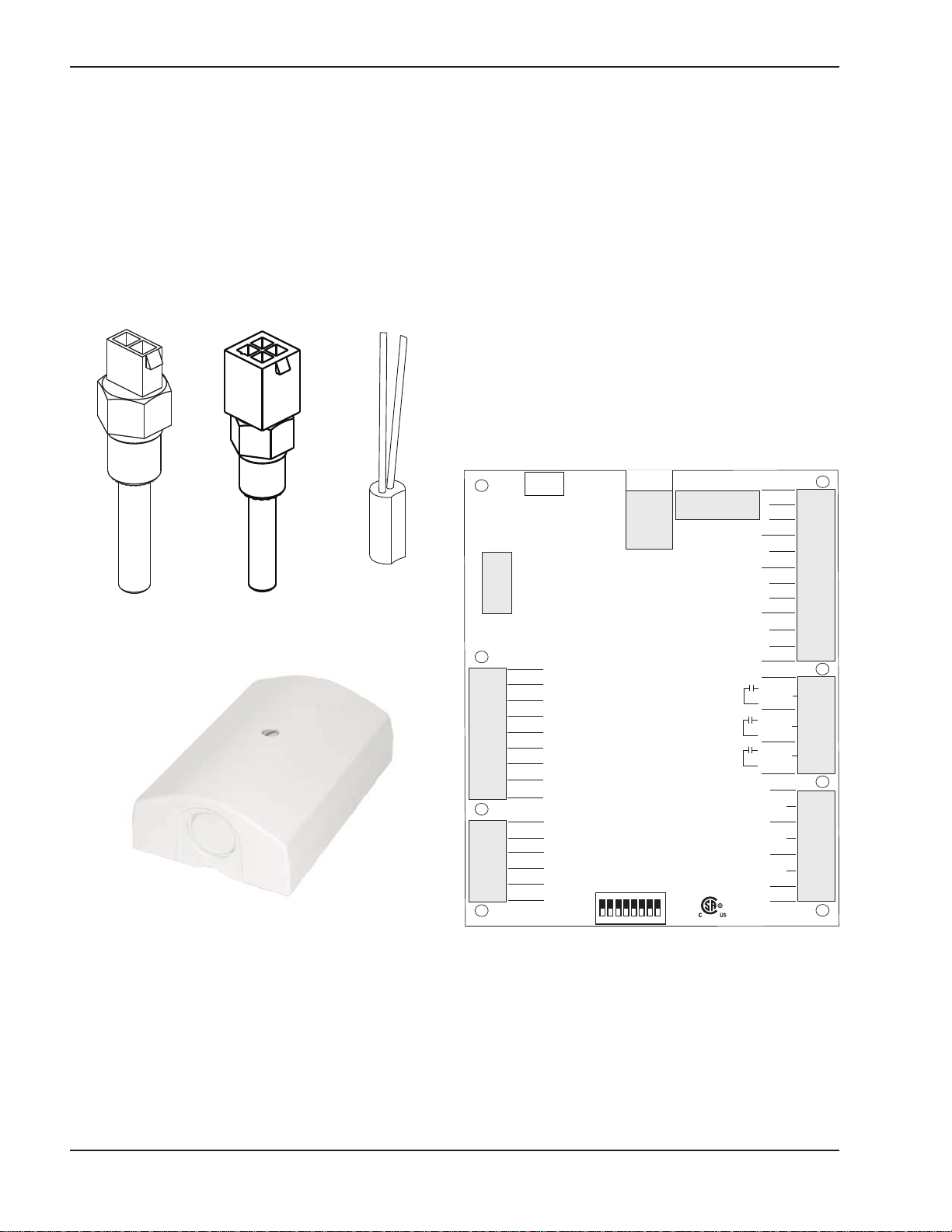

VERSA IC®Unit Type ID Card

The VERS IC®Identification Card (ID Card) is a small

circuit card that determines the operating parameters

for each individual model by unlocking the correct pro-

gram within the VERS ®Platform Ignition Module

(referred to simply as PIM™ throughout the rest of this

manual). It is permanently affixed to the chassis of the

heater and MUST be present for the heater to operate.

DANGER: In the event of ID Card failure, field

replacement can only be performed by a Raypak

Employee or contracted Representative and must be

replaced with an ID Card of the same number.

Serious risk of severe personal injury, death or sub-

stantial property damage if not correctly serviced.

Fig. 8: VERSA®PI ™ ID Card

through to the VERS ®Control Board which is

required to provide those additional functions. uxiliary

sensors, such as the indirect supply / pool return sen-

sor, connect directly to the VERS ®Control Board for

other enhanced functions depending on the mode

selected. For detailed wiring information, refer to the

I&O Manual for the product being installed.

Quick Start Set-up &

Programming Tips

1. Determine the piping arrangement for your partic-

ular application by referencing the pplication

drawings and descriptions on pages 9 to 34.

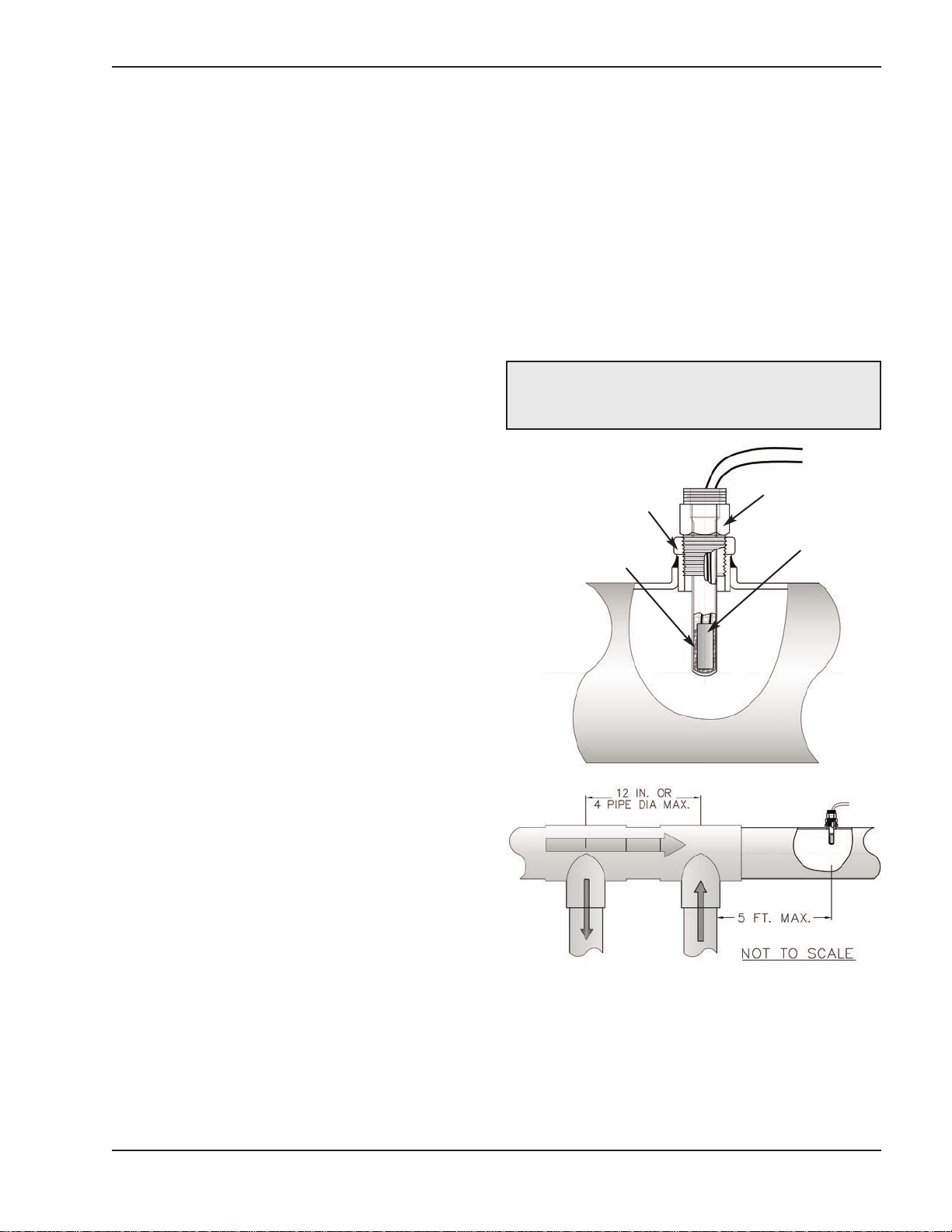

2. Install the System Sensor, Outdoor/ ir Sensor,

Indirect DHW Sensor as necessary as depicted in

the above referenced pplication drawing.

3. Wire the sensors to the VERS IC®system as

described on the wiring diagram of the respective

model (see model I&O wiring diagrams). Sensor

wires should be routed to the heater in separate

conduit.

CAUTI N: Sensor and control wiring must NOT be

run in conduit or chases with line voltage.