Raypak B-206A-MN-C ASME User manual

Other Raypak Gas Heater manuals

Raypak

Raypak 206A Manual

Raypak

Raypak 130 User manual

Raypak

Raypak Residential Series User manual

Raypak

Raypak 266L User manual

Raypak

Raypak 206A Manual

Raypak

Raypak 336A Manual

Raypak

Raypak 300 Manual

Raypak

Raypak 514-824 User manual

Raypak

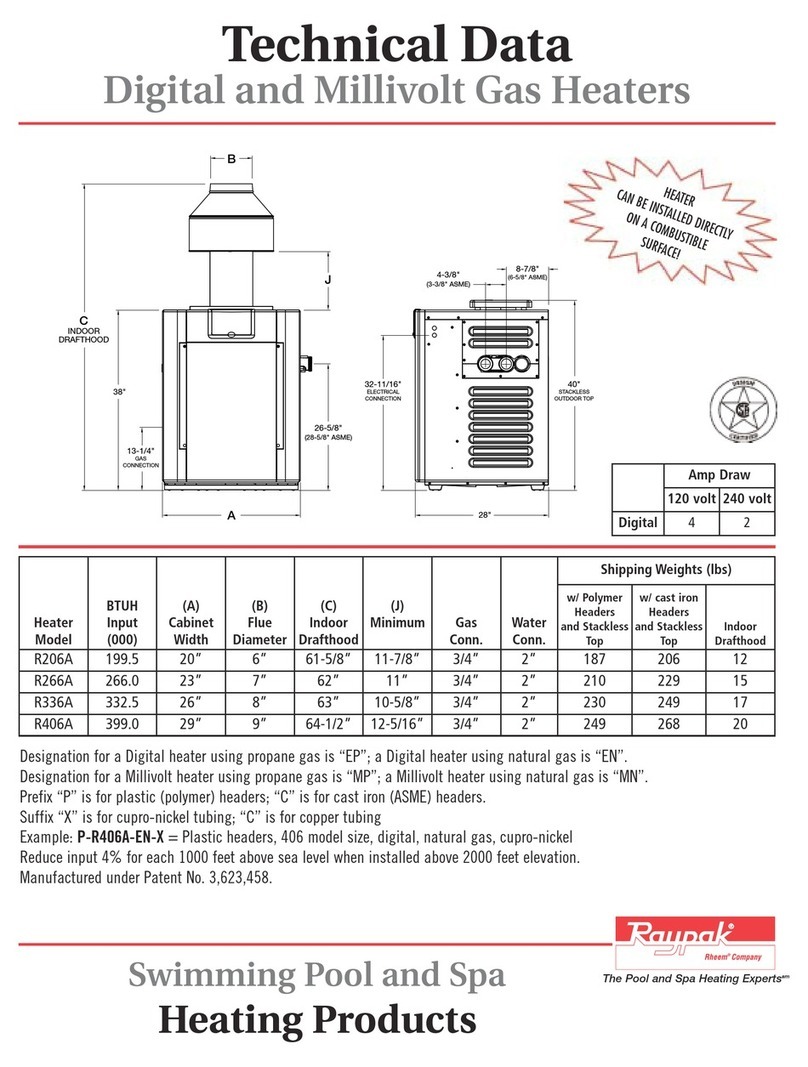

Raypak Digital and Millivolt Gas Heater Instruction manual

Raypak

Raypak 266A User manual

Popular Gas Heater manuals by other brands

Desa

Desa ROPANE CONSTRUCTION HEATERS owner's manual

Desa

Desa BCLP375 owner's manual

Robur

Robur Line F1 Series User, installation and service manual

Superior

Superior BGE18NV Installation and operation instructions

Dru

Dru Room-sealed atmospheric gas-fired heating... user manual

klover

klover TKR 35 user guide

Rothenberger Industrial

Rothenberger Industrial 035984 instruction manual

Hargrove

Hargrove Timberland Glow Operation and installation guide

Kinder

Kinder Cameo BF Installation and maintenance instructions

Qlima

Qlima GH 438 B-2 Directions for use

Desa

Desa 125-R owner's manual

Gasmate

Gasmate AH100 Series instructions

Brant Radiant Heaters

Brant Radiant Heaters QTD Series User instruction

Medallion

Medallion MBP20TLB OWNER'S OPERATION AND INSTALLATION MANUAL

Sealey

Sealey LP35.V5 instructions

Italkero

Italkero Falo Evo User manual and assembly instructions

Desa

Desa 30LP owner's manual

Williams

Williams 2509822A owner's manual