3 - Preliminary Checks

3.3 Check Zero Weight (Check

Tare)

You should check the zero weight

regularly as part of the daily operating

routine. ALWAYS check zero weight if

the machine has been left idle for

some time and has cooled down.

The lifting procedure is different for

Dynamic and Static weighing modes.

Note the weighing mode set on the

channel you have selected and follow

the appropriate procedure below.

1. Ensure that the bucket is completely

empty. Crowd (roll) the bucket right

back as far as it will go.

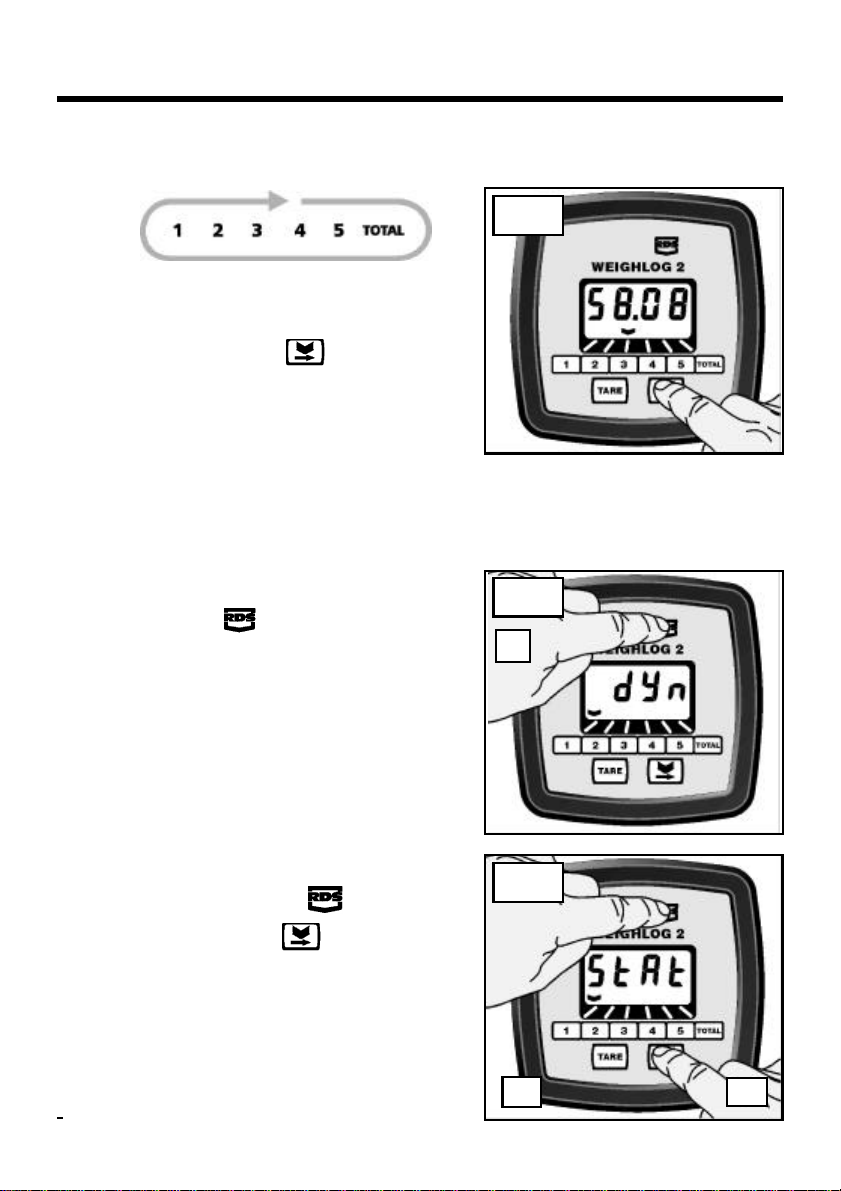

2.a Dynamic weighing mode :Lift the

bucket through the reference position.

A single beep will be heard. The

display will show a value.

2.b Static weighing mode :Lift the bucket

up to the reference position and stop.

A single beep will be heard. If you lift

too high a second beep is heard and

the display will show 4 dashes (fig. 6).

If so, lower the bucket back down to

the reference position.

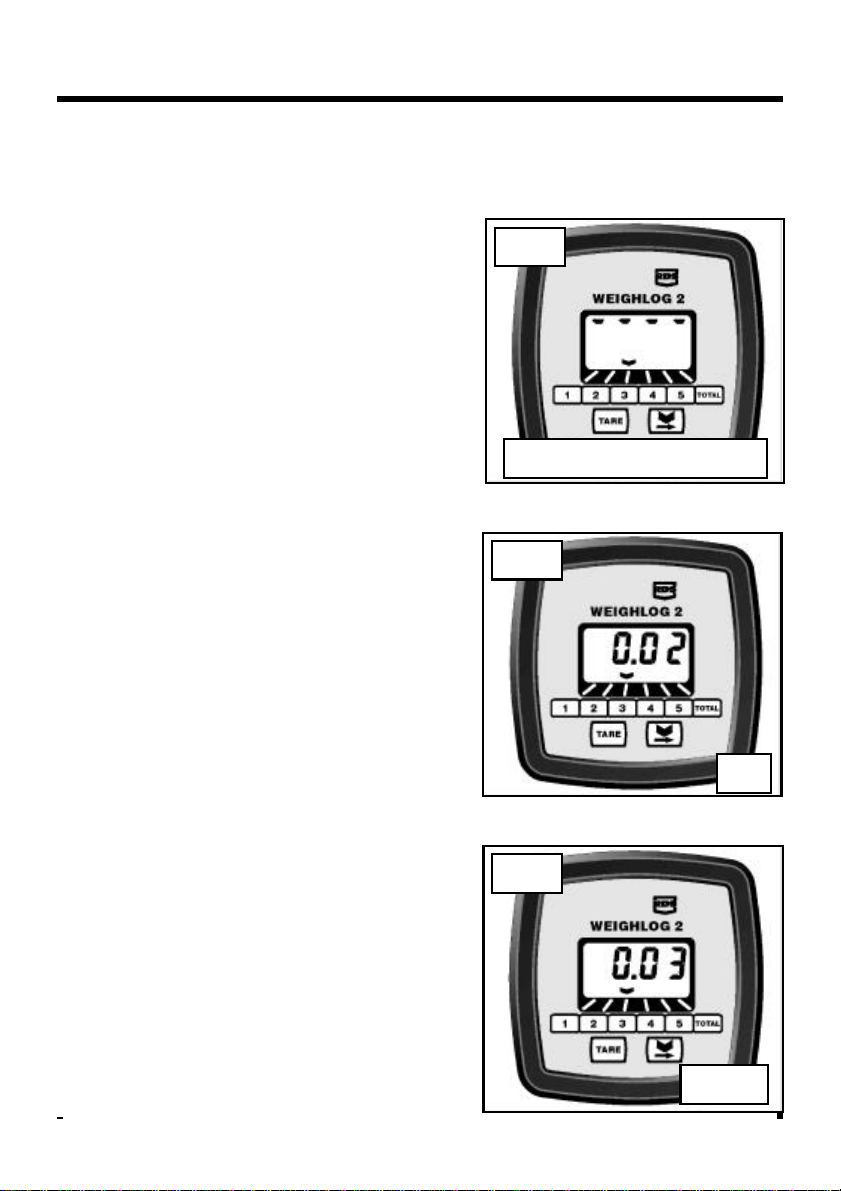

3. If the display reads within ±0.02 (20

kgs) or in "USA" units ±40 (40 lbs)

(fig. 7), this is within the repeatability

of the Weighlog system and can be

accepted without zeroing the weight.

Simply continue loading as normal.

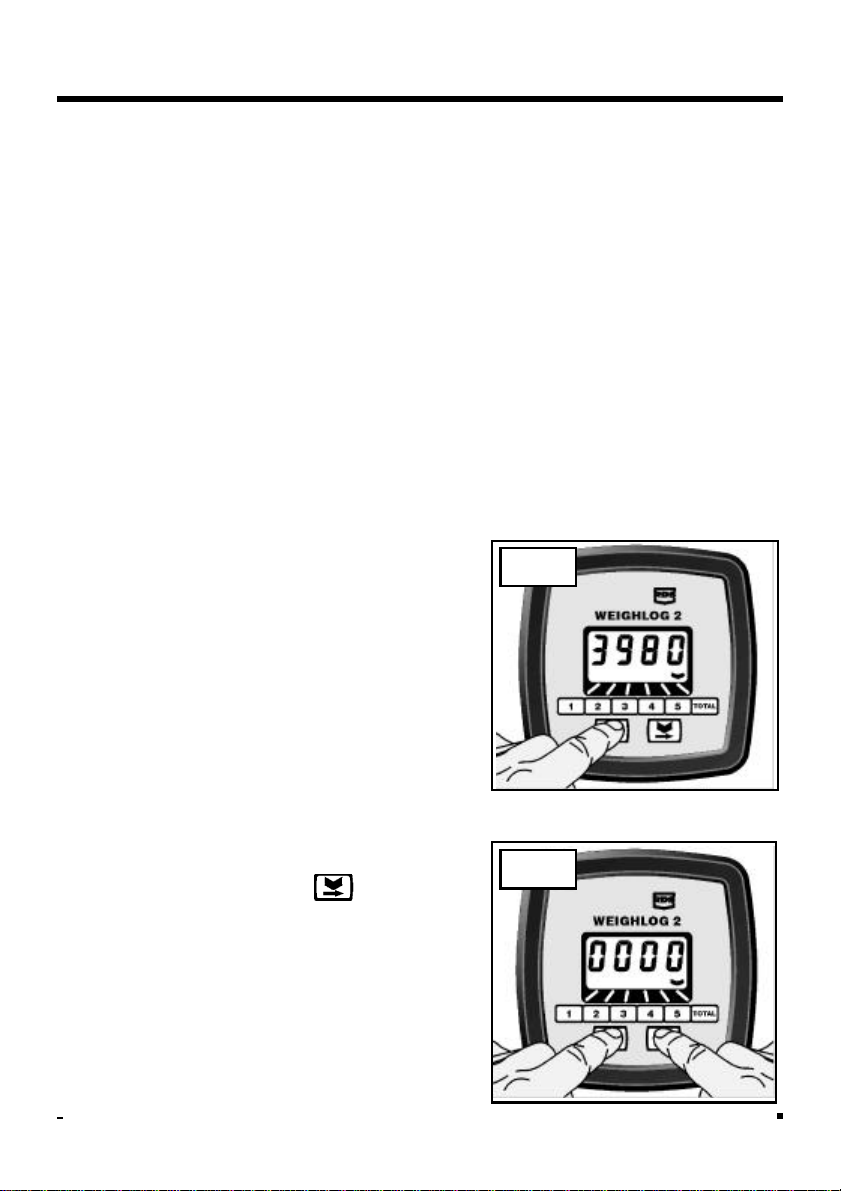

4. If the display reads more than ±0.02

(20 kgs) or in "USA" units ±40 (40 lbs)

(fig. 8), then you should zero the

weight (see 3.4).

OK

Not OK

Static mode - Load too high

Fig. 8

Fig. 7

Fig. 6