OVERVIEW

4

1. Overview

The Weighlog 200 is intended for se on ind strial and agric lt ral loading

shovels, fore-end loaders, back-hoe loaders, (loader side only), tipping

trailers and tipping tr cks.

It meas res, displays and records the net weight lifted, normally based on

sensing the lift system hydra lic press re. Press re sensing is problematic

on certain types of eq ipment d e to the design of the hydra lic system. In

these instances strain sensing technology may be sed instead. The

Weighlog 200 also has lift speed compensation to improve acc racy when

weighing dynamically.

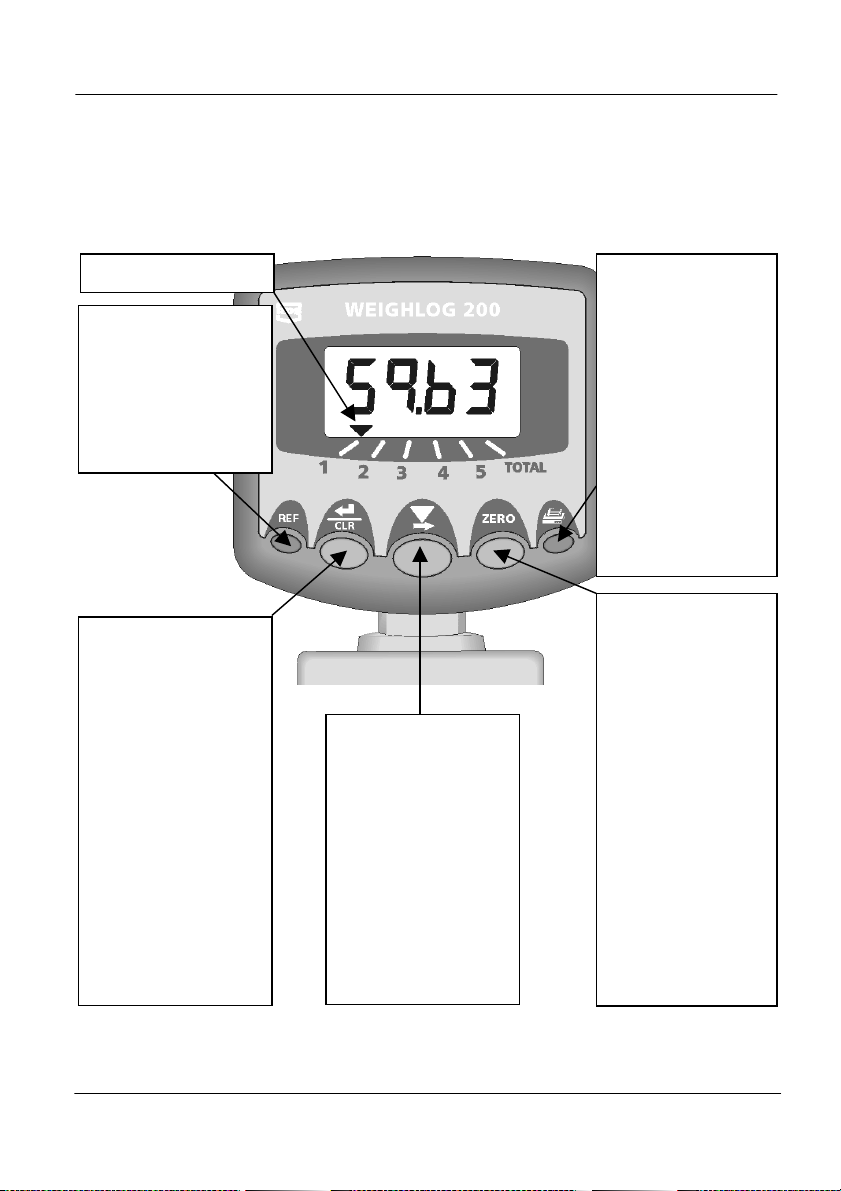

The instr ment has an ill minated 4-digit LCD display, 5 front panel switches,

an external Load Enter B tton, and an internal a dible alarm. An external

a dible alarm is optional. The instr ment is normally powered on via the

ignition circ it and recalls the f nction selected when last sed.

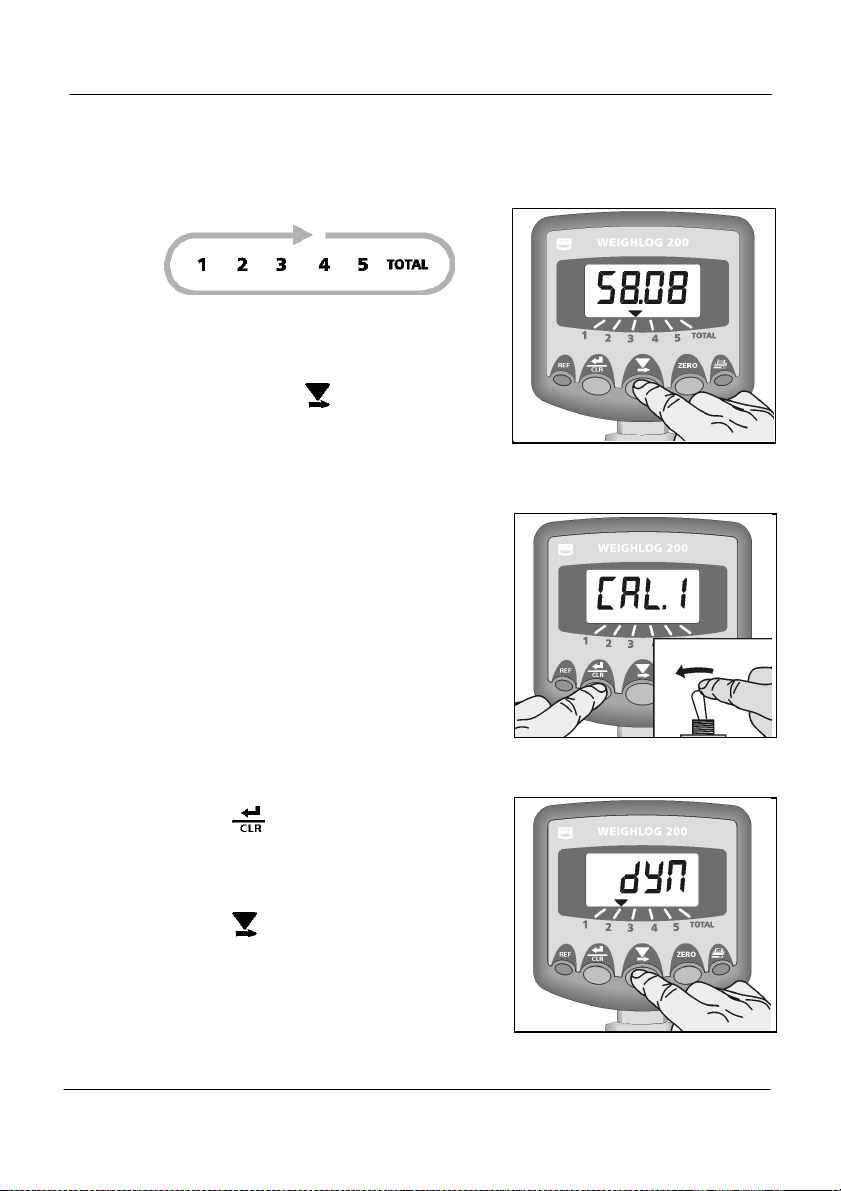

There are 5 individ al display channels available. These can be calibrated for

p to 5 different loader attachments, different trailers or different

commodities. Each channel will display the net b cket weight lifted at any

time. If req ired the b cket weight can be added to the total for the channel

in se and will also be added to the TOTAL channel, which acc m lates

weight from all of the five channels.

The instr ment has a Load Alarm f nction. If the load exceeds a preset

fig re, an a dible alarm is triggered and the weight display will flash.

The instr ment can be config red to a tomatically print each b cket weight

entered, or individ al load total when the instr ment is zeroed for the next

load. Also, yo can at any time print o t the acc m lated total for channel 1

to 5, and the Grand Total (channel 6).

For each channel yo can :

• Adj st the Weight Calibration Factor

• Set either Static or Dynamic Weighing Mode.

• Set the Zero Weight.

• Display and add the b cket weight to the s b-total.

• Receive a dible alarm confirmation of the zero and load entering.

• Print the last b cket weight a tomatically

• Print an acc m lated total

• Reset the acc m lated total (and a tomatically print a s mmary)

• Compensation for variable lift speed (dynamic weighing only)