CONTENTS

3

1OVERVIEW __________________________________________________________5

1.1 Introduction............................................................................................................................................................... 5

What is the difference between these two Approvals? ........................................................................................... 5

1.2 System Technical Details ......................................................................................................................................... 5

1.3 Calibration................................................................................................................................................................. 6

1.4 Weighing Units.......................................................................................................................................................... 6

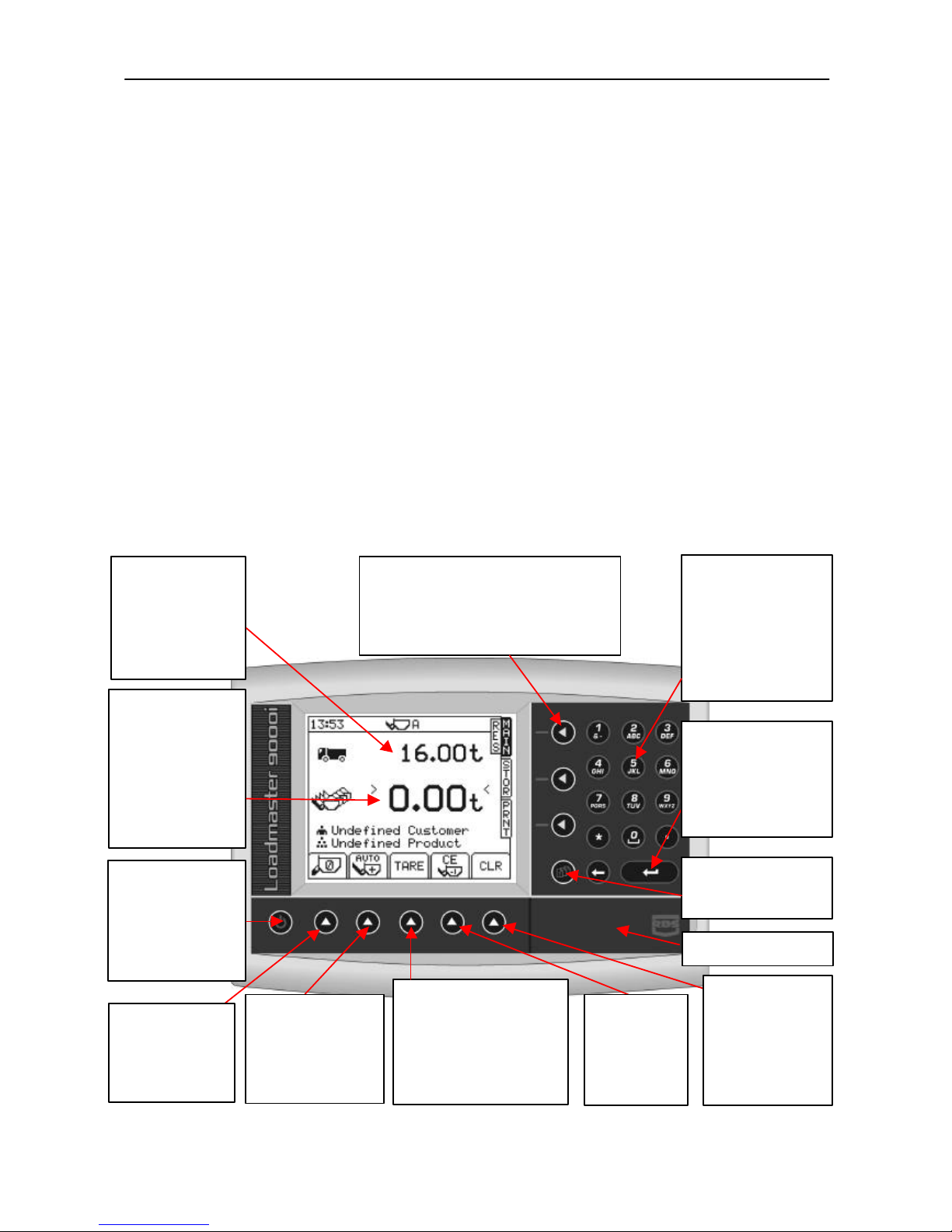

1.5 The Head Unit........................................................................................................................................................... 6

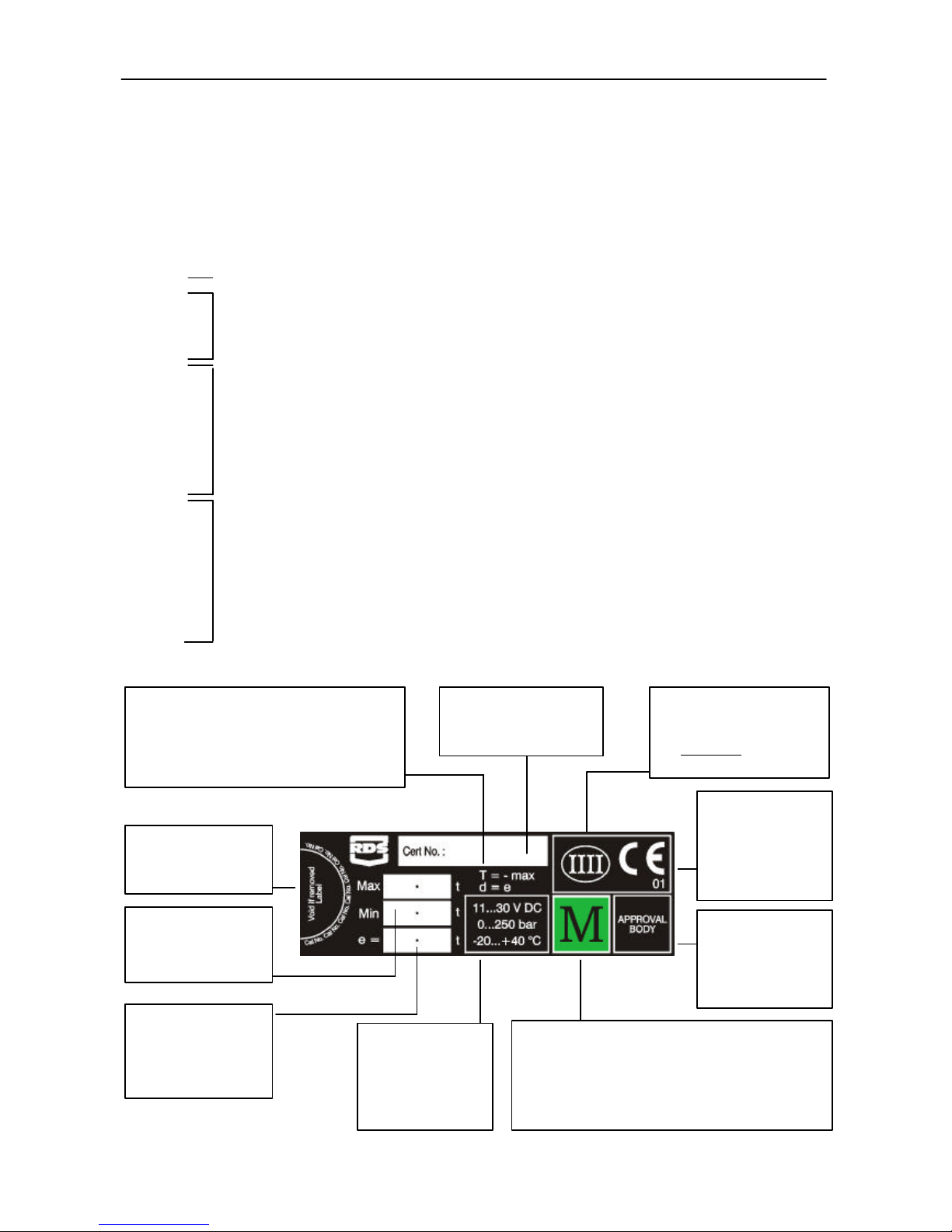

1.6 Approved Weighing Mode Certification................................................................................................................... 7

1.7 Loading Attachments................................................................................................................................................ 8

1.8 Menu keys................................................................................................................................................................. 8

1.9 Data Entry.................................................................................................................................................................. 8

2STARTUP ___________________________________________________________9

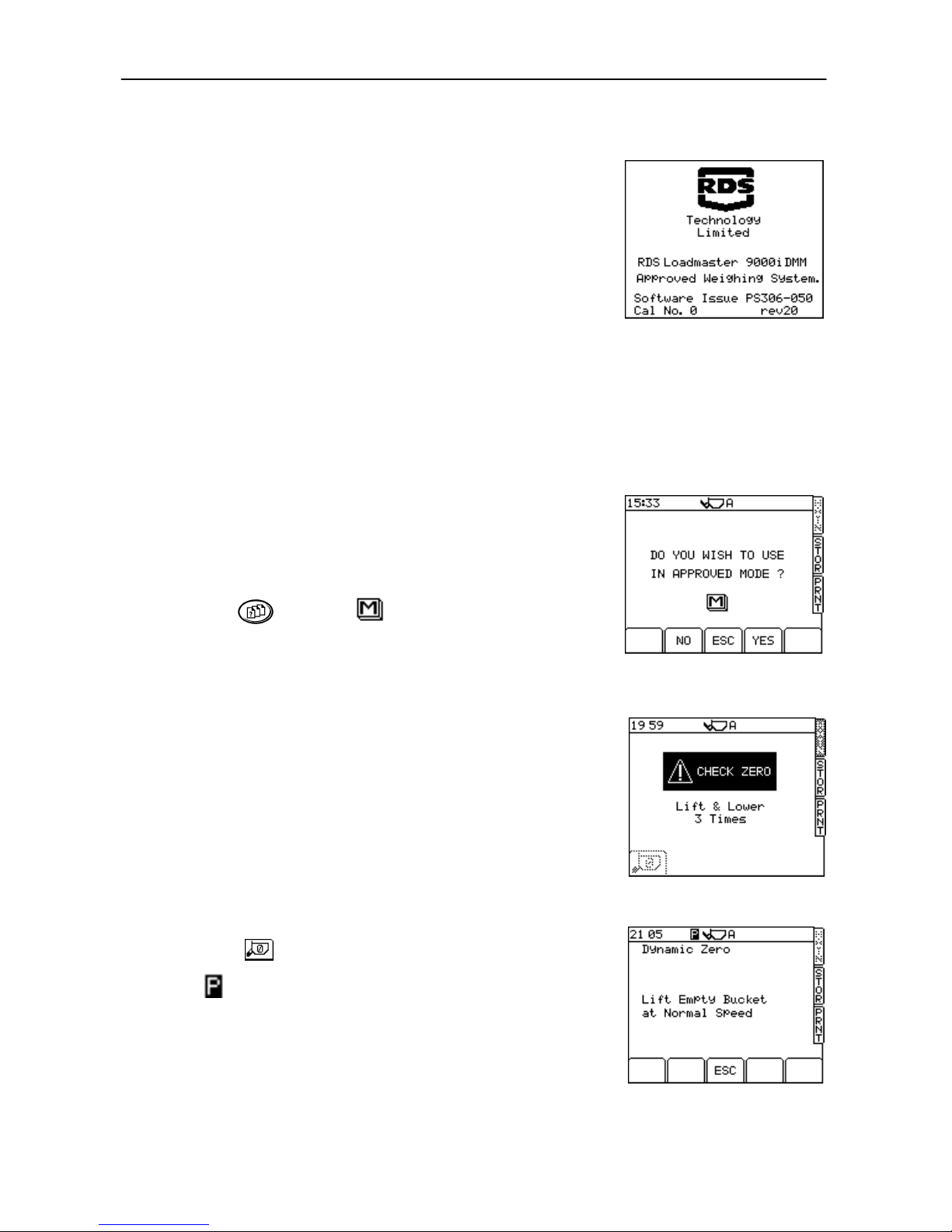

2.1 Switch On.................................................................................................................................................................. 9

2.2 Set Weighing Mode.................................................................................................................................................. 9

2.3 Zero Prompt .............................................................................................................................................................. 9

2.4 Zero ........................................................................................................................................................................... 10

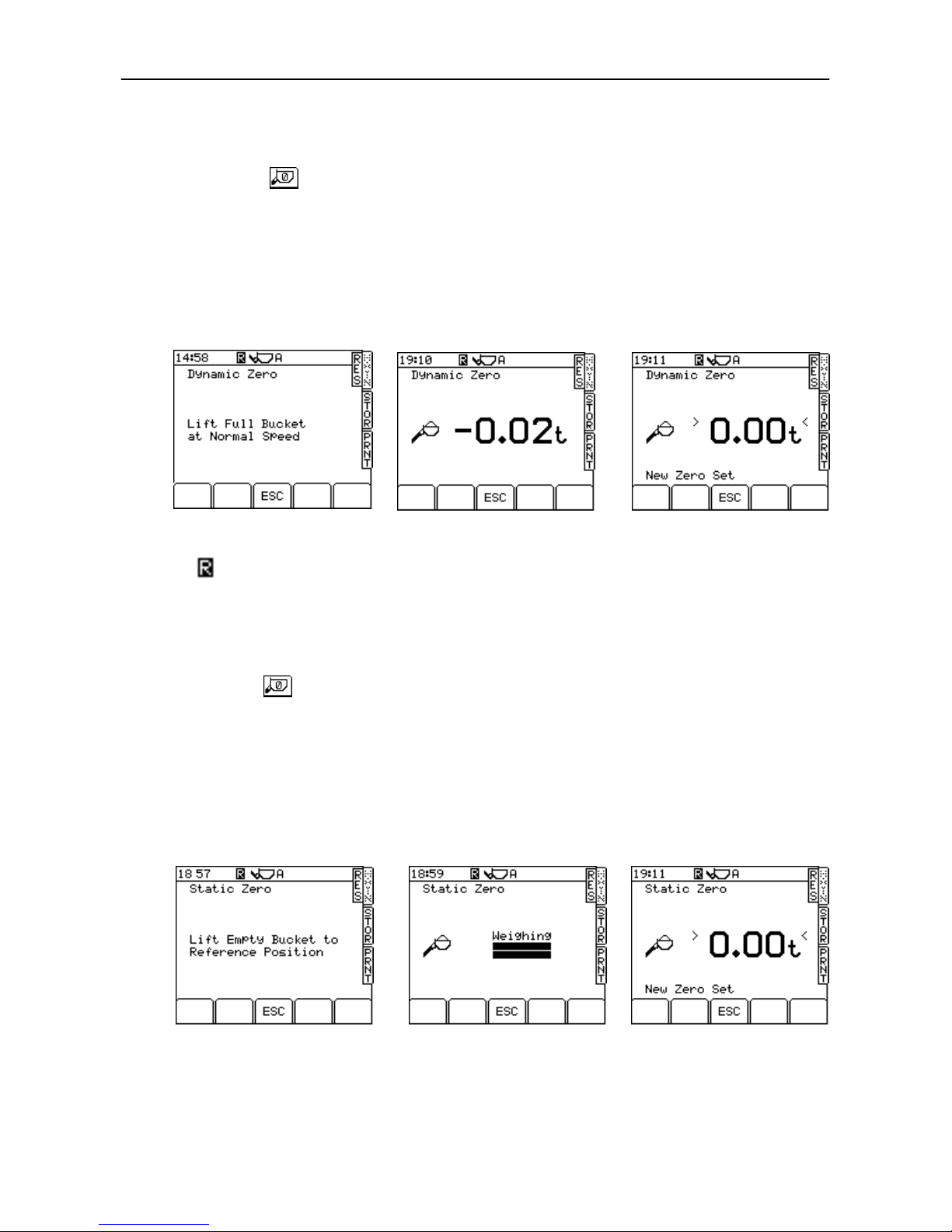

2.4.1 Dynamic Zero (Dynamic Mode)................................................................................................................ 10

2.4.2 Static Zero (NAWI Mode)........................................................................................................................... 10

2.4.3 Error Messages.......................................................................................................................................... 11

(i) Angle of Slope............................................................................................................................................ 11

(ii) Low Oil Temperature / Sensor Faults ....................................................................................................... 11

(iii) Crowd Bucket............................................................................................................................................ 11

(iv) Boom Sensor (Telehandlers only)............................................................................................................ 11

2.5 Set Target Load......................................................................................................................................................... 11

2.6 Set Preset Tare.......................................................................................................................................................... 11

2.6.1 Cancel Preset Tare .................................................................................................................................... 11

2.6.2 Re-weigh function (Tare –1)...................................................................................................................... 12

2.7 Set the Load Enter mode (AWI only)....................................................................................................................... 12

3WEIGHING IN APPROVED MODE ______________________________________13

3.1 Dynamic Weighing ................................................................................................................................................... 13

3.2 "Live Last Bucket" Weighing (Dynamic only).......................................................................................................... 13

3.3 Static Weighing......................................................................................................................................................... 14

3.4 Selecting Stores Index.............................................................................................................................................. 15

3.4.1 Store Index Search Function .................................................................................................................... 15

3.4.2 Set Target Weight ...................................................................................................................................... 16

3.5 Error Messages......................................................................................................................................................... 16

3.5.1 Angle of Slope............................................................................................................................................ 16

3.5.2 Low Oil Temperature / Sensor Faults ....................................................................................................... 16

3.5.3 Anti-bounce................................................................................................................................................ 16

3.5.4 Maximum Weight Exceeded ..................................................................................................................... 16

3.6 Zero Alarms............................................................................................................................................................... 16

Zero Limit Exceeded (more than ±2% drift)............................................................................................................ 16

Zero Error (more than ±10%) ................................................................................................................... 17

3.7 Clear Last Entry......................................................................................................................................................... 17

3.8 Reset for next load.................................................................................................................................................... 17